Open-pit bench blasting hole distributing method

A technology of step blasting and open-pit mines, which is applied in the direction of blasting, etc., can solve the problems that are not conducive to the standardized operation of drilling rigs and explosives mixed trucks, reduce the efficiency of drilling and charging operations, and the difficulty of implementing hole layout methods, so as to improve the drilling efficiency. Hole and charge efficiency, simple and fast hole layout, and the effect of improving the blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

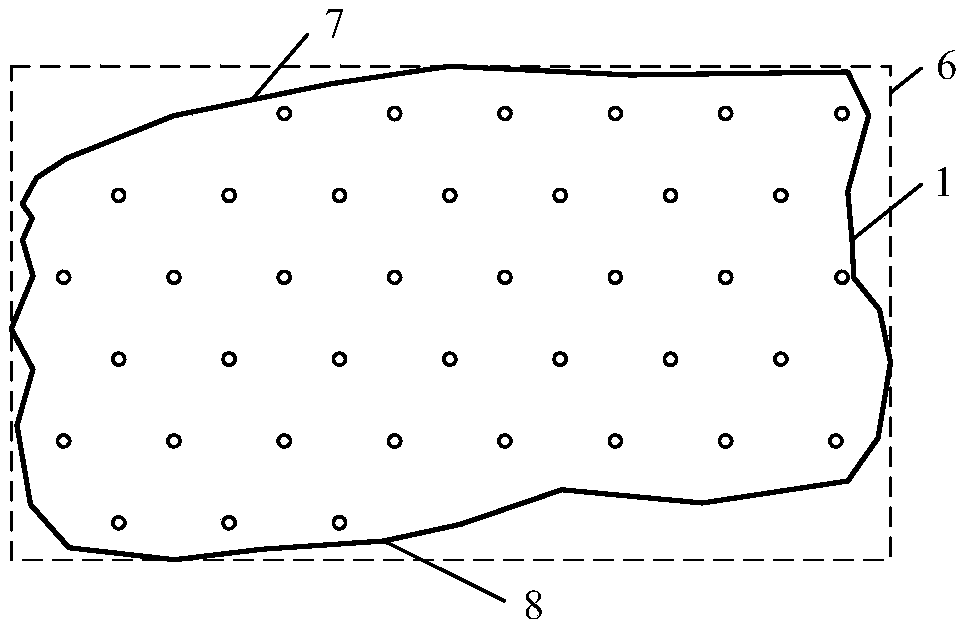

[0033] Below in conjunction with the accompanying drawings, the present invention will be further described by taking the step blasting hole layout of a certain open-pit mine as an example.

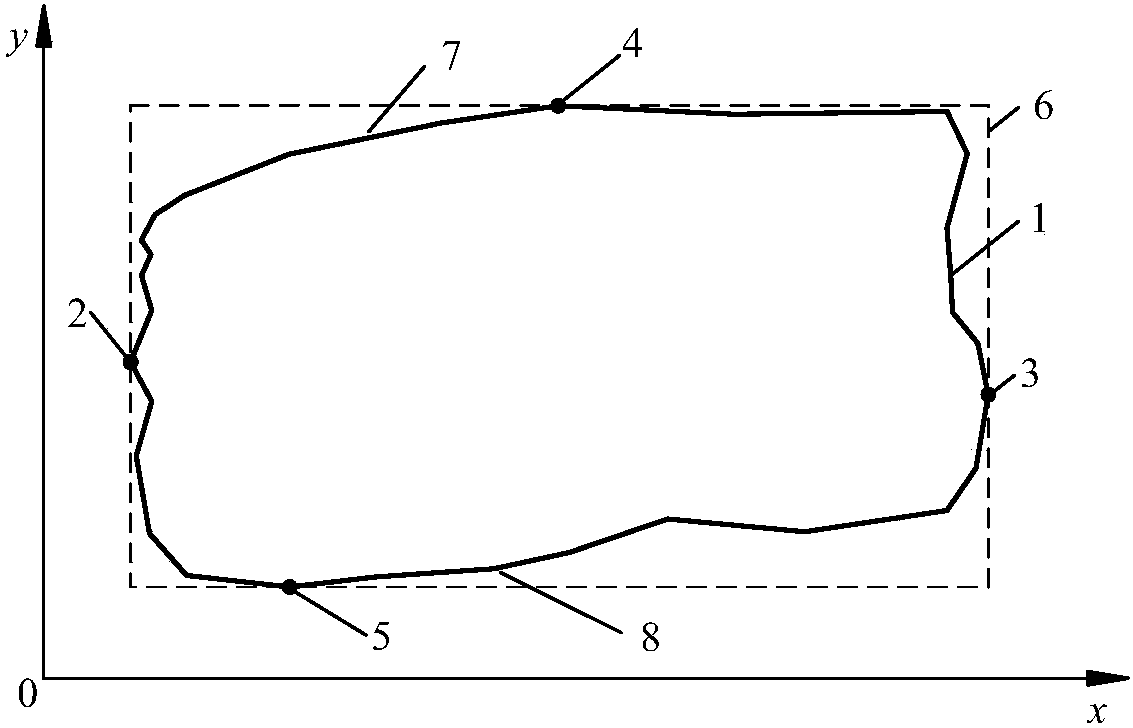

[0034] a. Determine the rectangular area

[0035] A blast zone 1 in the open-pit mine figure 1 As shown, take the abscissa x of the minimum abscissa point 2 and the maximum abscissa point 3 in the explosion zone 1 2 =6.4,x 3 =69.9, the vertical coordinate y of the maximum point of vertical coordinate 4 and the minimum point of vertical coordinate of 5 4 =45.5,y 5 =6.7, with (x 2 ,y 4 ), (x 3 ,y 4 ), (x 3 ,y 5 ), (x 2 ,y 5 ) is the apex, and a rectangular area 6 is formed. The length of the rectangular area is 69.9-6.4=63.5m, and the width is 45.5-6.7=38.8m.

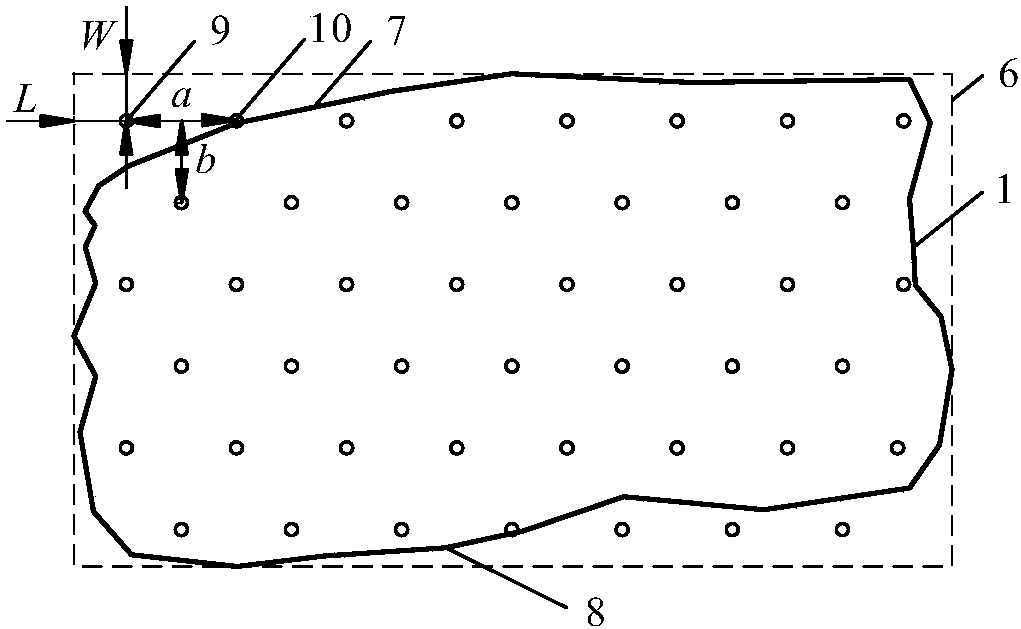

[0036] b. Layout holes in a rectangular area

[0037] b1 determines the direction of the hole layout

[0038] The method for judging whether the slope top line (7) or the rear boundary line (8) of the blast zone is stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com