A magnetic levitation train track and its joint device

A technology for maglev trains and joint devices, applied in the field of maglev, can solve problems such as increased project cost, limited expansion and contraction, and increased construction difficulty, so as to prevent excessive rail gaps, ensure reliability and safety of use, and increase the range of change Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

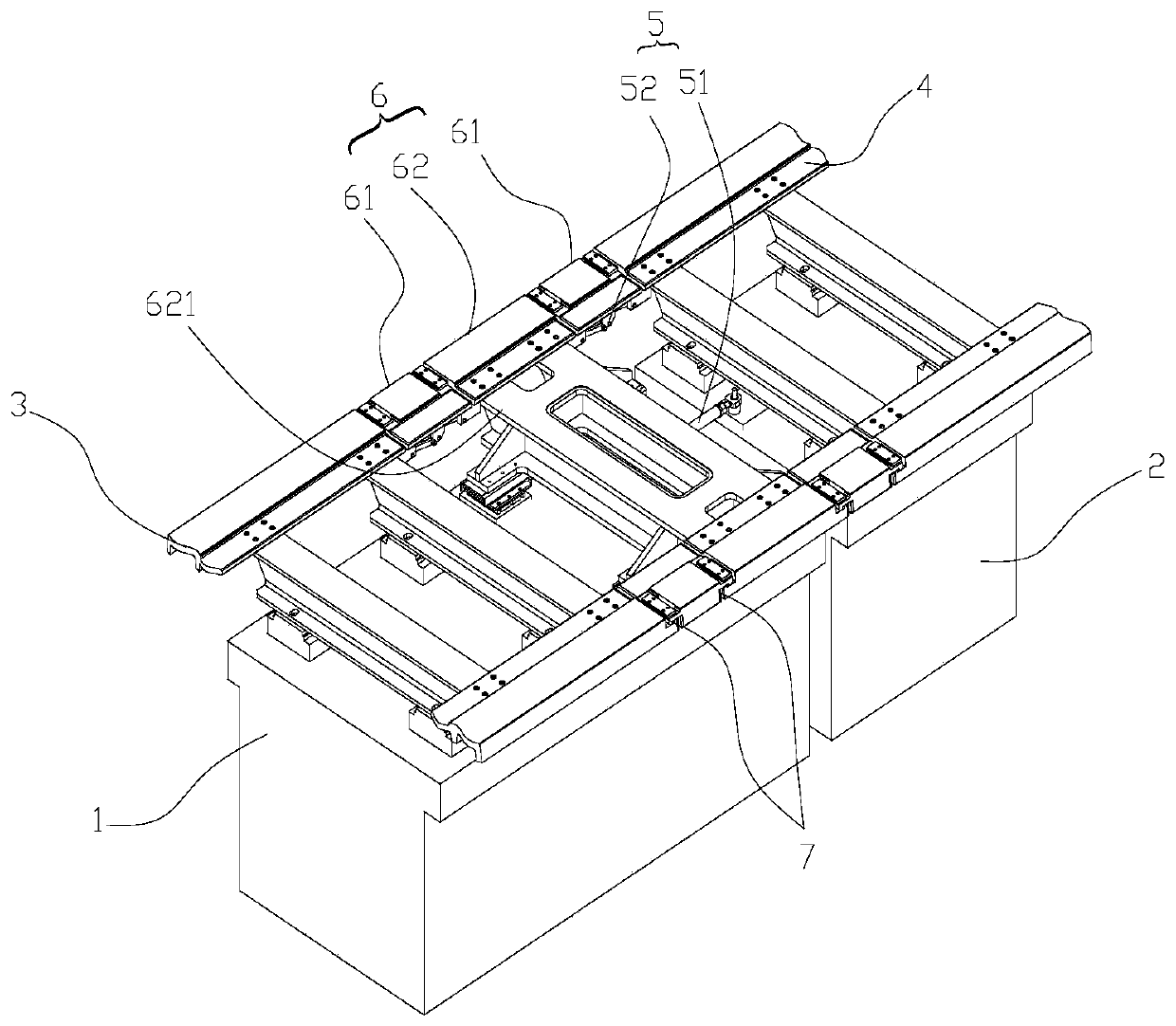

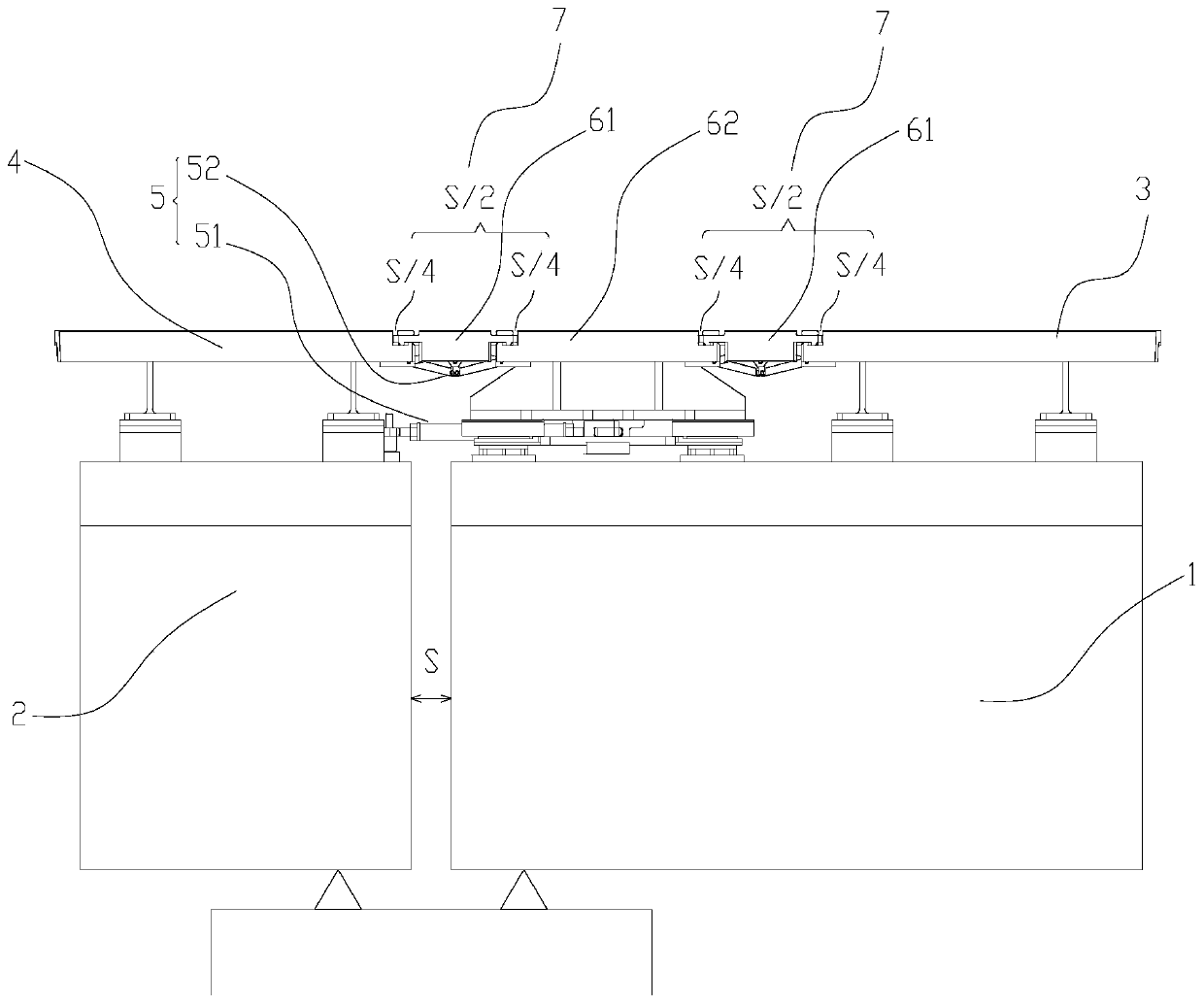

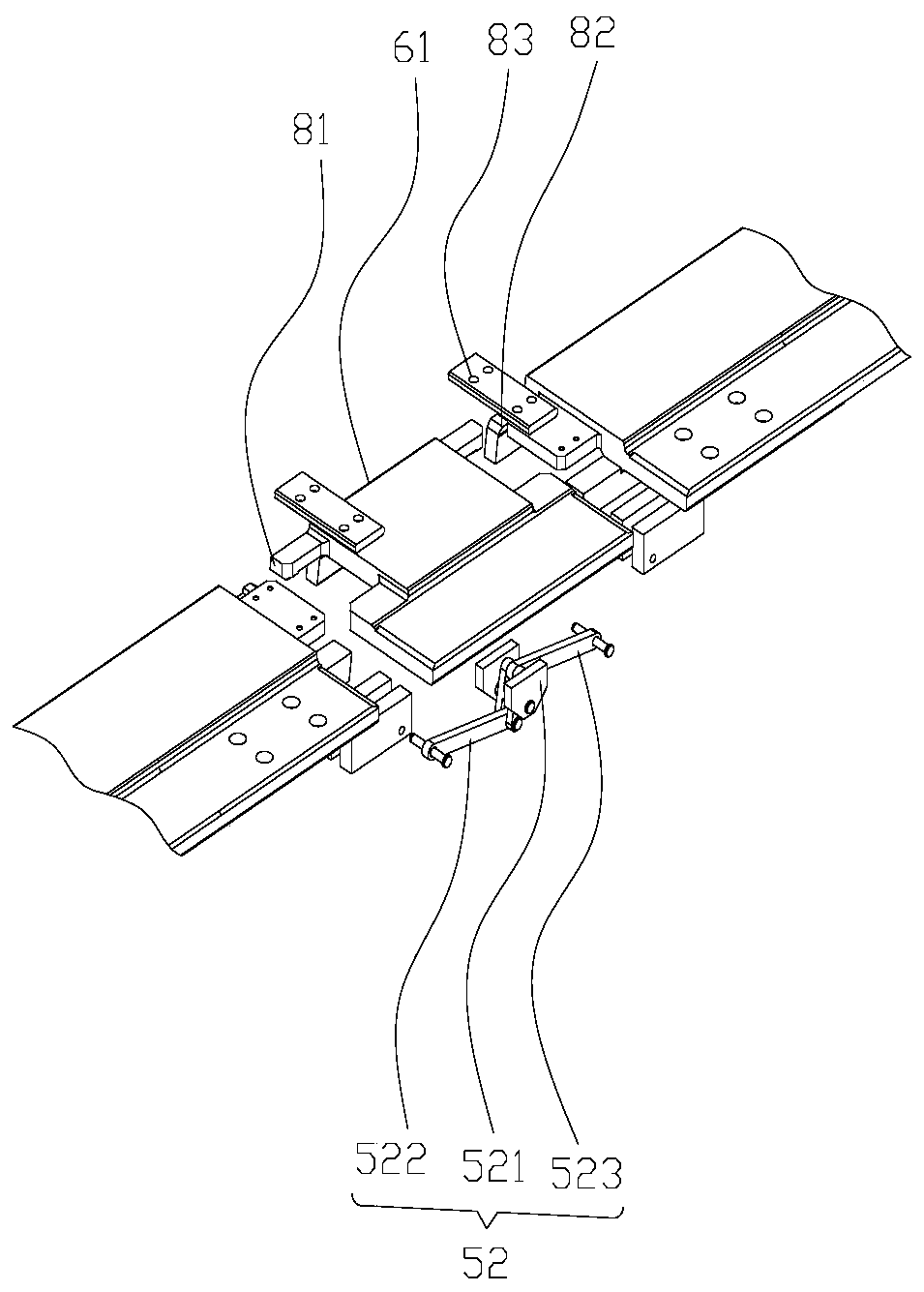

[0055] like figure 1 and figure 2 As shown, in the first specific embodiment, the connecting rail 6 includes a moving rail 62 and joints 61 longitudinally movably connected to the two ends of the moving rail 62, and the joints 61 at both ends are connected to the first guide rail 3 and the second guide rail 4 respectively. Longitudinal movable connection; there is a gap at both ends of the joint 61 between the first guide rail 3 and the moving rail 62, and the gaps at both ends jointly form the rail gap 7 between the first guide rail 3 and the moving rail 62; between the moving rail 62 There are gaps at both ends of the joint 61 with the second guide rail 4 , and the gaps at both ends together form a rail gap 7 between the moving rail 62 and the second guide rail 4 . When the distance between the first track beam 1 and the second track beam 2 changes, the rail gap distribution mechanism 5 drives the moving rail 62 to move longitudinally, and then adjusts the gap between the ...

Embodiment 2

[0067] like Figure 6 and Figure 7 As shown, in the second specific embodiment, the connecting rail 6 of the present invention may include a joint 61 and at least two moving rails 62, and adjacent moving rails 62 may be connected by joints 61, and the adjacent moving rails A rail gap 7 is formed between the rails 62, that is, the inside of the connecting rail 6 may also have a rail gap 7, or each moving rail 62 may be connected longitudinally and sequentially to form a rail body, as the connecting rail 6; the two ends of the connecting rail 6 pass through the joint 61 are respectively connected with the first guide rail 3 and the second guide rail 4, and the joints corresponding to each joint 61 can adopt longitudinal movable connection, and the gaps at both ends of each joint 61 jointly form the rail seam 7; the rail seam distribution mechanism 5 can drive each moving rail 62 to move longitudinally, to limit each rail gap 7.

[0068] The joint 61 can adopt the structure in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com