Rotary distributor

A technology of rotating distributor and distribution plate, applied in rotary conveyors, conveyors, transportation and packaging, etc., can solve problems such as insufficient connection, stringing, poor stability, etc., to achieve stable and reliable device, high positioning accuracy, Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

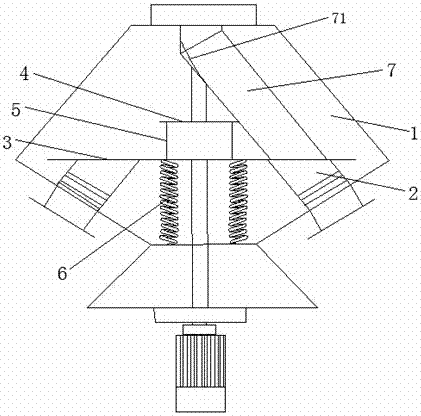

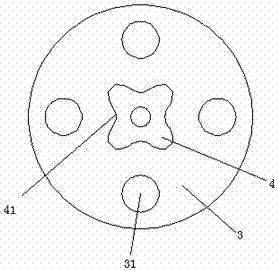

[0021] Such as Figure 1-4 As shown, a rotary distributor includes an upper cone 1, a distribution plate is installed on the lower part of the upper cone 1, and a plurality of evenly distributed distribution chambers are arranged on the distribution disk, and a sealing cover is installed on the lower part of the distribution chamber. A motor is installed on the lower part of the sealing cover, a reducer is installed on the upper end of the motor, and a rotating shaft is installed on the upper end of the reducer. A feeding pipe 7 is installed on the mouth, and the feeding pipe 7 is fixed on the rotating shaft. A flexible hose 2 is installed on each distribution bin, and one end of the flexible hose 2 is fixed on the fixing hole 31 of the inner fixing plate 3 of the upper cone 1. , and the other end protrudes from the upper cone 1 to connect with the feed pipe of the storage bin; the fixed plate 3 is fixed with a pattern plate 4, and the edge of the pattern plate 4 is provided w...

Embodiment 2

[0023] The difference between embodiment 2 and embodiment 1 is that in order to reduce the load on the motor, we set up a pneumatic cylinder on the lower part of the fixed plate 3, and the pneumatic cylinder, reducer, and motor are all connected to the PLC controller. When the feed pipe rotates to the flexible When the hose is in place, the pneumatic cylinder lifts the fixed plate 3, and the feeding pipe 7 is stuck in the arc groove of the pattern plate 4 for accurate positioning. When the feeding is completed, the pneumatic cylinder shrinks the feeding pipe 7 and the flexible soft The tube 2 is detached, and the feeding tube will not touch the fixed plate 3 when it rotates under the driving action of the rotating shaft, which can effectively reduce noise. The rotation of the rotating shaft and how to position the feeding tube belong to the prior art, and will not be described in detail here repeat.

[0024] In order to ensure that the feed pipe 7 and the flexible hose 2 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com