Dual-purpose fixture

A fixture and dual-purpose technology, applied in the field of processing fixtures, can solve the problems of external surface damage of parts, increased production costs, and large number of fixtures, and achieves the effect of saving fixture costs, processing time, and labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

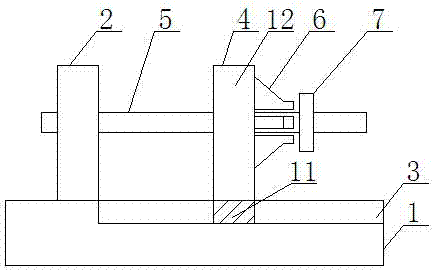

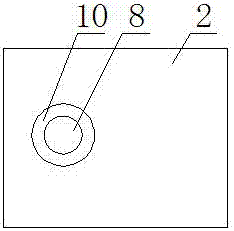

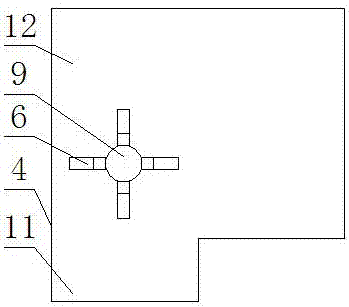

[0016] like Figure 1~3 Shown, a kind of dual-purpose fixture, it comprises base plate 1, and base plate 1 is provided with vertical plate 2, and vertical plate 2 is provided with adjustable screw rod 5, and vertical plate 2 is provided with through hole 8, and through hole 8 is provided with Bearing 10, the end of bearing 10 and adjustable screw rod 5 cooperates. The bottom plate 1 is provided with a chute 3, the chute 3 is provided with a slide plate 4, the slide plate 4 is provided with a screw hole 9 which cooperates with the adjustable screw rod 5, and the adjustable screw rod 5 on the right side of the slide plate 4 is provided with a nut 7 , The nut 7 is threadedly connected with the adjustable screw rod 5 . One side of the slide plate 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com