An electromagnetic heating type electromagnetic forming device and method for warm plate

An electromagnetic forming and heating technology, which is applied in the field of warm forming and processing of metal plates and electromagnetic forming devices for electromagnetic heating warm plates, achieves the effects of high heating efficiency, improving forming plasticity and increasing electromagnetic heating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

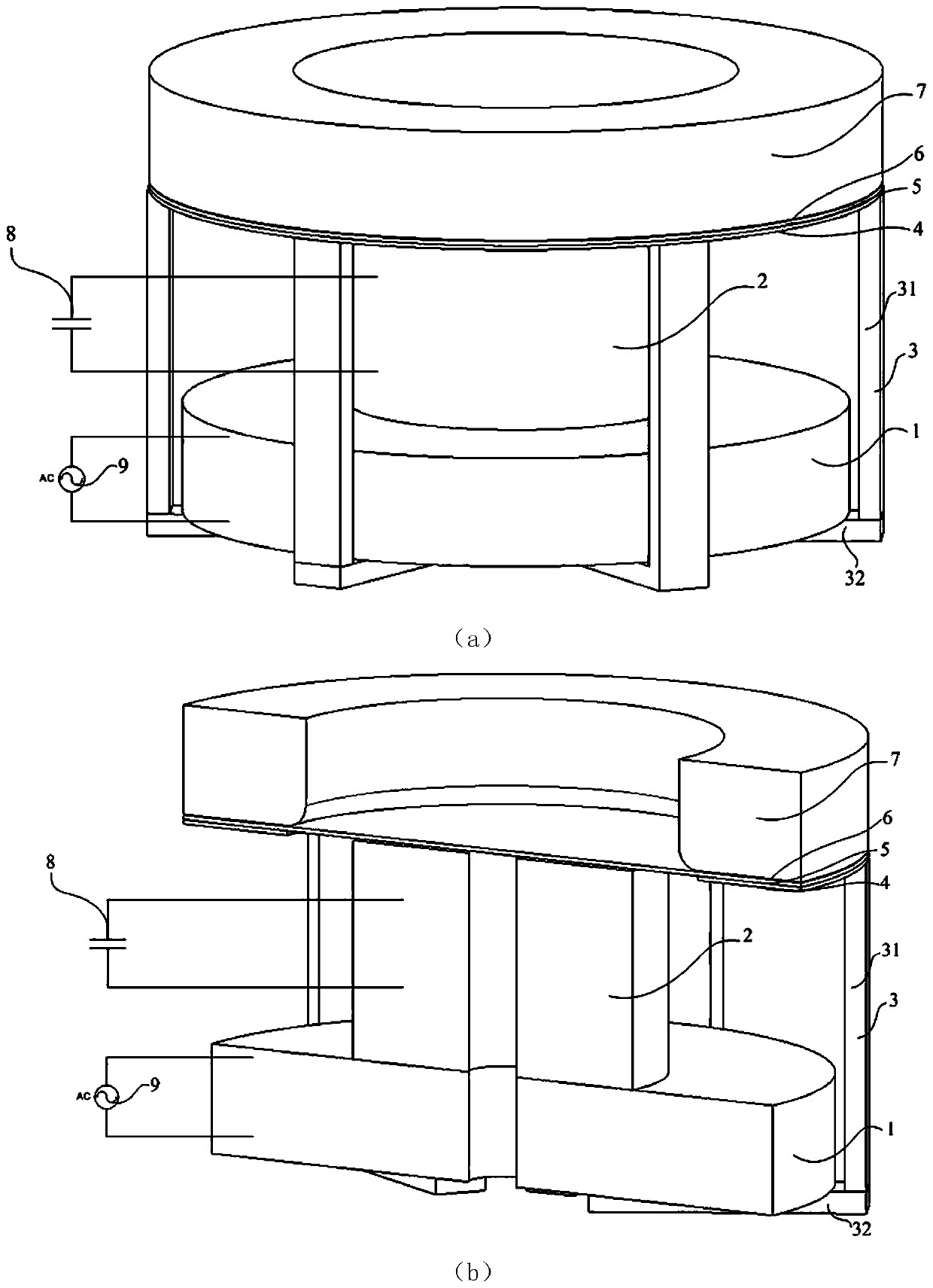

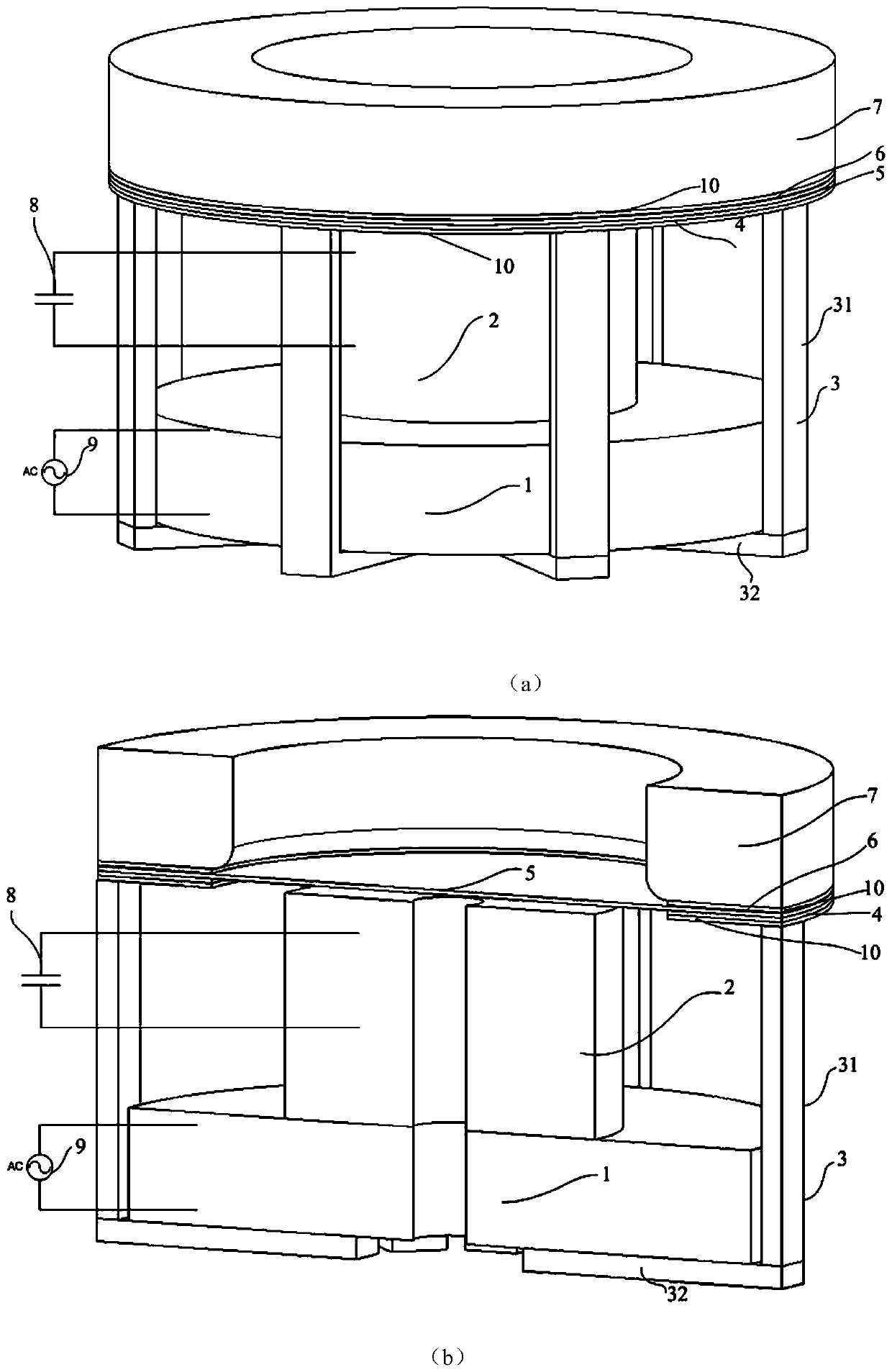

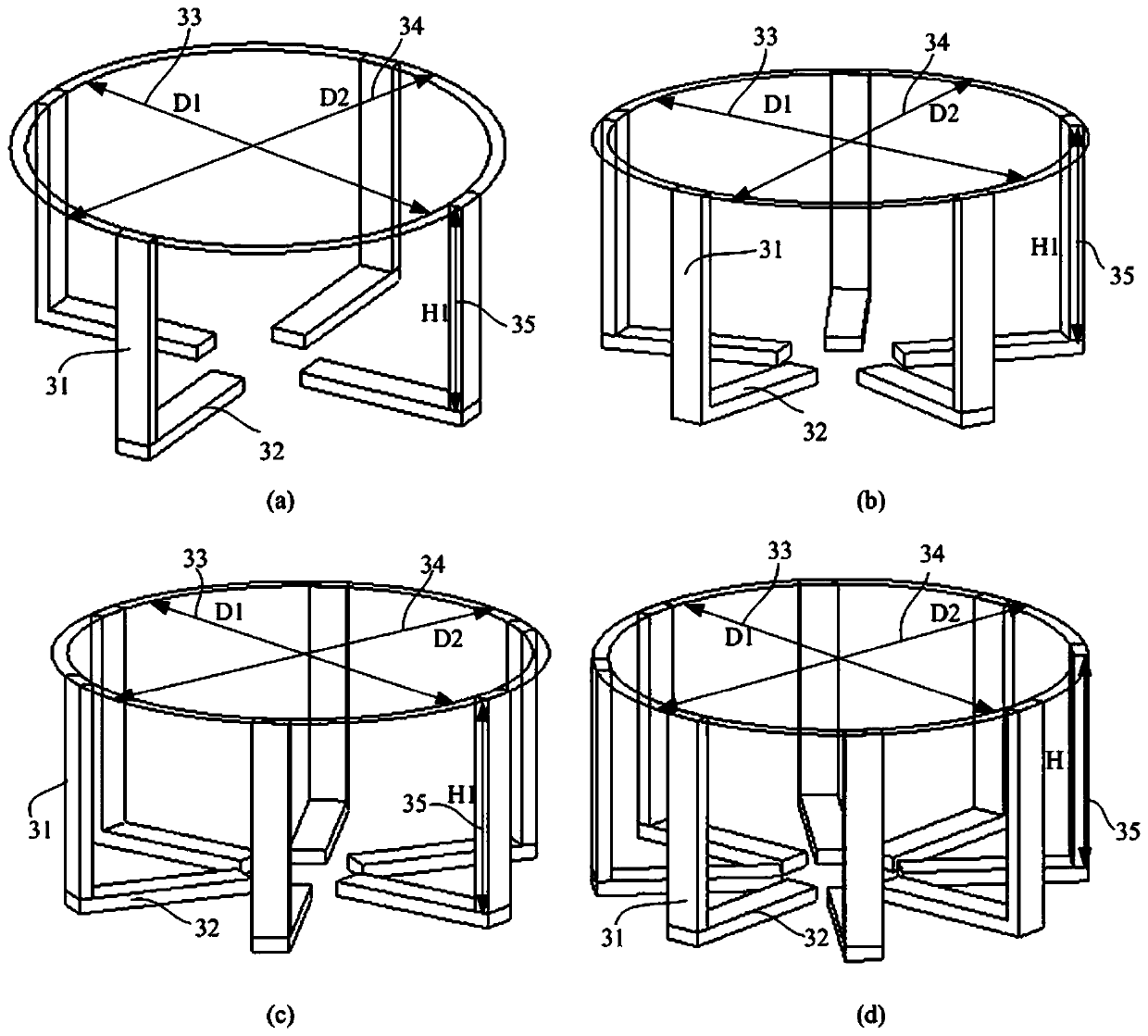

[0082] Step 1: Follow the image 3 (c) Arrange six L-shaped soft ferrite core materials evenly according to the circumference, so that one side (vertical side) of the L-shaped soft ferrite core material is parallel to the axis of symmetry, and the other side (horizontal side) ) point to the axis of symmetry; Step 2: according to Figure 5 Indicates that the heating coil is wound with multiple insulated copper wires with a diameter of less than 0.3mm; the shaped coil is wound with a single insulated copper wire and a reinforcement material; figure 1 As shown, the heating coil and the forming coil are placed in the space surrounded by the vertical side of the L-shaped soft ferrite core material in turn, and the axes of the heating coil and the forming coil are symmetrical to the L-shaped soft ferrite core material Axes are collinear; Step 4: According to figure 1 As shown, at the end of the vertical side of the L-shaped soft ferrite core material, place the ring-shaped heating...

Embodiment 2

[0084] Step 1: Follow the image 3 (d) Arrange eight L-shaped soft ferrite core materials evenly according to the circumference, so that one side (vertical side) of the L-shaped soft ferrite core material is parallel to the axis of symmetry, and the other side (horizontal side) ) point to the axis of symmetry; Step 2: according to Figure 5 Indicates that the heating coil is wound with multiple insulated copper wires with a diameter of less than 0.3mm; the shaped coil is wound with a single insulated copper wire and a reinforcement material; figure 2 As shown, the heating coil and the forming coil are placed in the space surrounded by the vertical side of the L-shaped soft ferrite core material in turn, and the axes of the heating coil and the forming coil are symmetrical to the L-shaped soft ferrite core material The axes are collinear; Step 4: Stick the ring-shaped heat insulating sheet on the side of the ring-shaped heating silicon steel sheet away from the formed workpie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com