Emergency and precise load shedding control system and method based on distributed feeder line automation

A feeder automation and control system technology, used in information technology support systems, emergency protection circuit devices, power network operating system integration, etc., can solve problems such as active power shortage, grid frequency drop, and large grid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

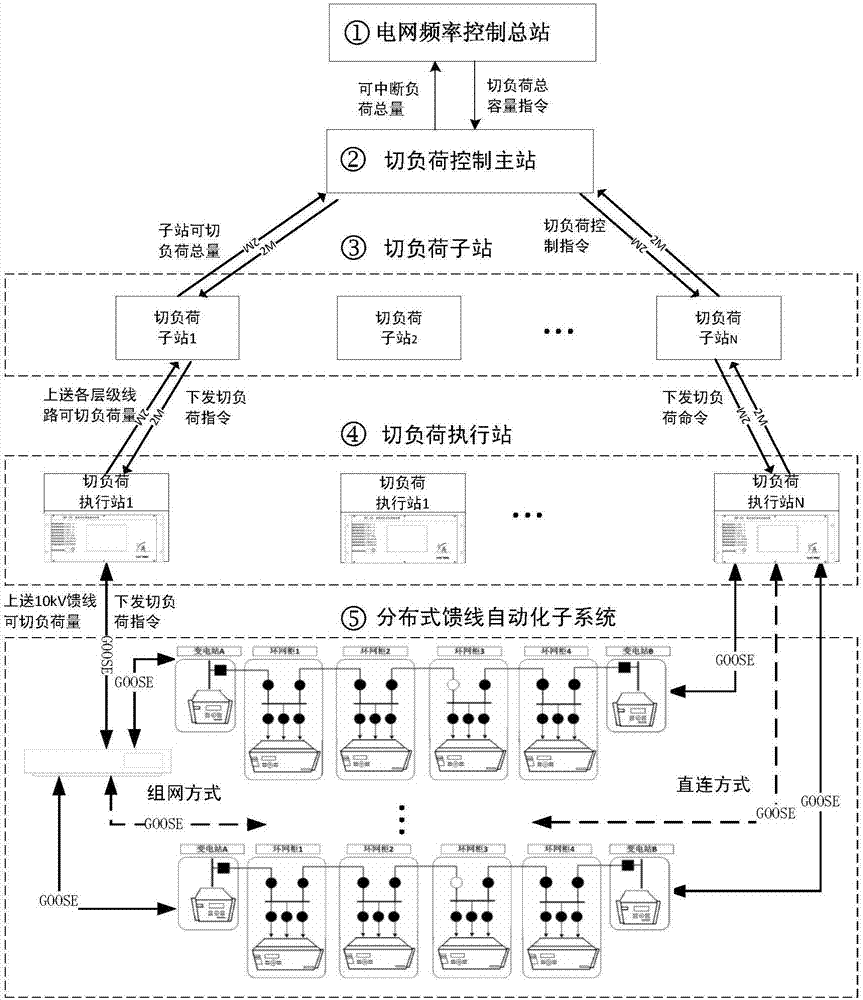

[0107] Such as figure 1 As shown, the system is designed according to the five-layer architecture of the regional power grid frequency control main station, load shedding control master station, load shedding control substation, load shedding execution station and distributed feeder automation subsystem. The specific functions are as follows:

[0108] Regional power grid frequency control central station: The grid frequency control central station can be set up in the UHV converter station. After the high-power DC power loss, the grid frequency control central station is responsible for formulating control strategies according to the amount of DC power loss. According to multi-DC coordinated control and pumped storage The priority of unit control and fast load shedding control is to issue load shedding total capacity commands to the load shedding control master station.

[0109] Load shedding control master station: The load shedding control master station can be installed in ...

Embodiment 2

[0116] Embodiment 2 Based on the IEC 61850 emergency precise load shedding control system model

[0117] According to the modeling idea of IEC 61850, each terminal device in the distributed feeder automation subsystem includes SERVER object, LD logical device and LN logical node. The modeling includes two service access points: S1 (MMS service) and G1 (GOOSE service). A SERVER class is modeled at the G1 access point, which adopts the subscriber / publisher communication mode for communication between feeder terminals. The distributed feeder automation function establishes a proprietary LD, and the instance name is "FDIR". In addition to the common LLN0 and LPHD LNs of LD, the FDIR object also includes OSFA (distributed feeder automation function), TSFA (test function), MSFA (status information) three logical nodes. In order to realize the emergency precise load shedding control function, a new ALDS (load shedding function) logical node is added.

[0118] Table 1 Logical node...

Embodiment 3

[0121] Embodiment 3 Working Mode of Emergency Precise Load Shedding Control System Based on Distributed Feeder Automation

[0122] The emergency precise load shedding control system based on distributed feeder automation provides two working modes, priority mode and topology mode. The two modes can be used independently or in conjunction with each other.

[0123] 3-1 priority mode

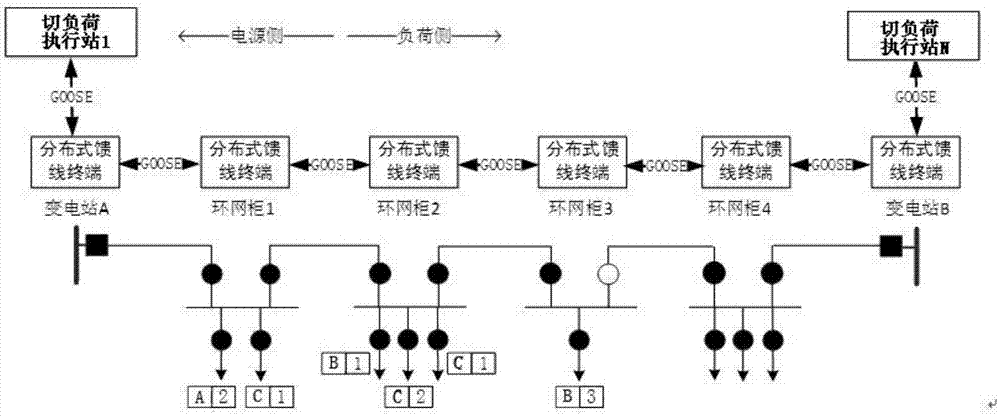

[0124] Priority mode is suitable for 10kV power distribution network including ring main unit nodes. Such as figure 2 As shown, according to the importance of the load carried by the power distribution branch circuit of the ring main unit, the load is divided into multiple levels, such as A-level load, B-level load, and C-level load. This mode can cut off the specified level of load in the power supply area, and realize the precise load shedding based on the load priority.

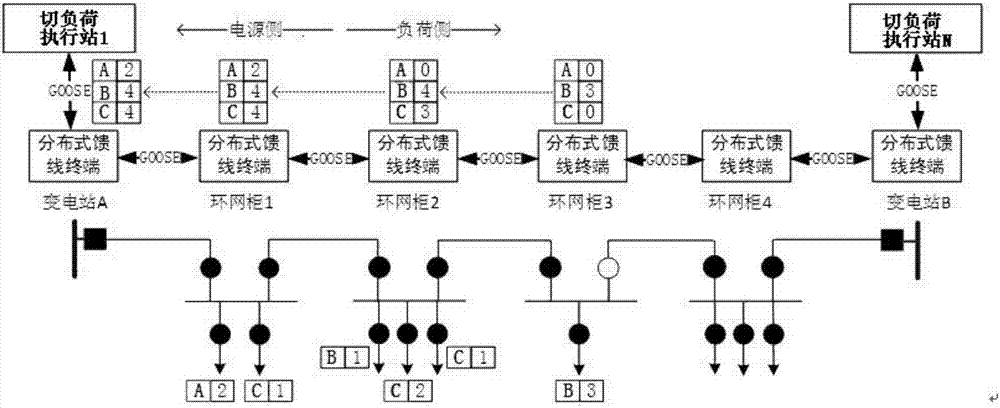

[0125] Such as image 3 As shown, the distributed feeder terminal installed at the ring main unit calculates the load c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com