Visual high-speed train roadbed granule vibration-subsidence recapitulation model test system

A model test, high-speed railway-based technology, applied in the direction of individual particle analysis, particle and settlement analysis, measuring devices, etc., can solve the problems of increasing uneven deformation, affecting the safety of train operation, and failure to detect deterioration in time, so as to achieve an intuitive test process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

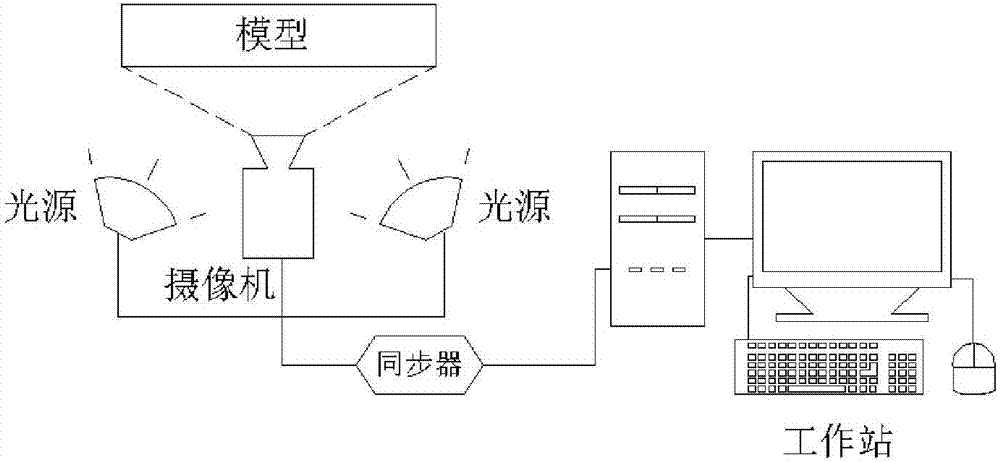

[0041] The following is a detailed description of the simulated test as an example.

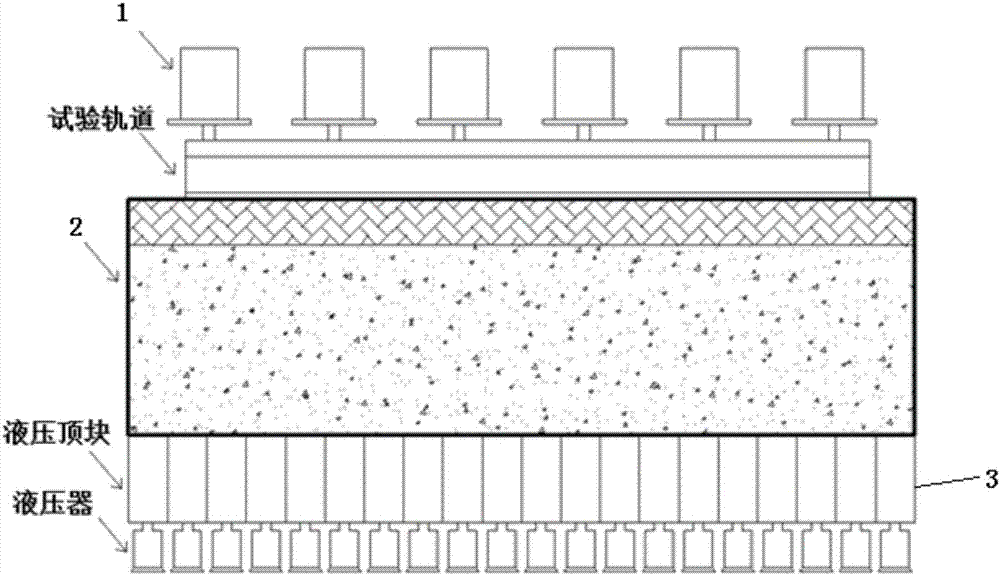

[0042] (1) Prepare the subgrade model: fill the test model in the test box with a size of 1000mm×600mm×300mm according to the laying form of the ballasted track subgrade, and the compactness of each layer of material shall be compacted according to the "High-speed Railway Design Code" TB10621-2009. Reality.

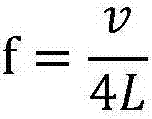

[0043] (2) The amplitude of the loading force of the exciter is 2.2kN according to the similarity ratio, and the waveform is a custom M-shaped wave. Calculation of the control parameters of the vibrator: assuming that the distance between adjacent fasteners in the model is L, the train speed is V, the loading frequency of the vibrator is f, and the phase difference of the vibration waveform of the adjacent vibrator is It is known that a wheel axle load is borne by 5 fasteners, then the exciter frequency is calculated according to the following formula:

[0044]

[0045] Adjacent ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com