Calcium-enriched compound fertilizer and preparation method thereof

A compound fertilizer and calcium-rich technology, applied in urea compound fertilizer, nitrogen fertilizer, potash fertilizer, etc., can solve the problems of low calcium sulfate solubility, high concentration, and inability to realize the coexistence of acyl nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

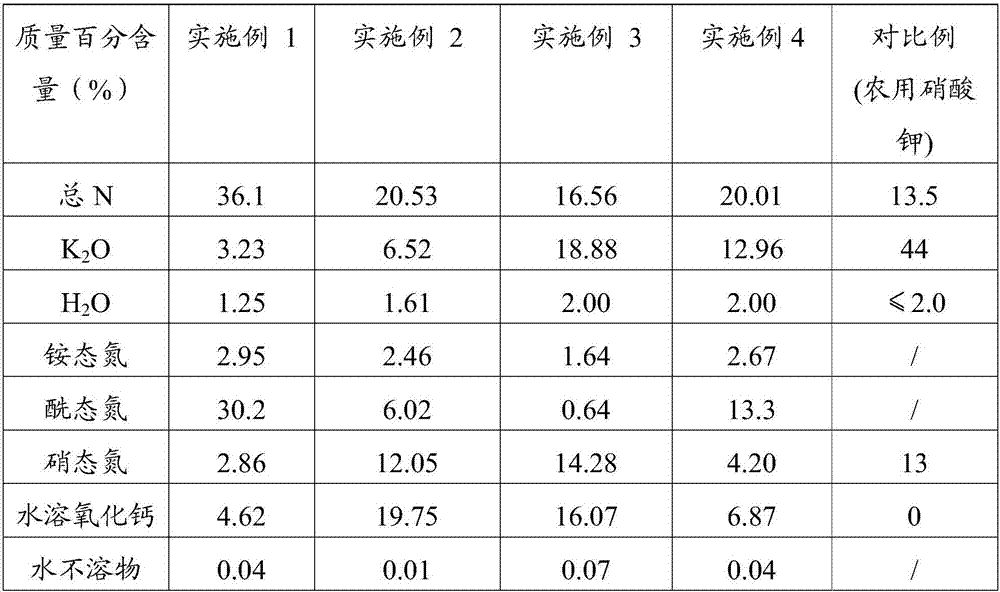

Examples

preparation example Construction

[0034] The preparation method of above-mentioned calcium-enriched compound fertilizer comprises the following steps:

[0035] Step S110, evaporating and concentrating the dilute urine to obtain urine.

[0036] Preferably, the mass concentration of dilute urine is 70%-80%, and the mass concentration of urine is 95%-99.75%.

[0037] Preferably, the temperature of the dilute urine is 80°C to 90°C.

[0038] It can be understood that the purpose of the urine is to provide urea. If solid urea is used in the subsequent steps, step S110 can be omitted, or if the raw material is urine with a mass concentration of 95% to 99.75%, no concentration is required. Steps can also be omitted.

[0039] Step S120, mixing urea with calcium source and potassium source to prepare slurry.

[0040] Urea may exist in the state of solid urea or in the state of urine. The mass concentration of urine is 95%-99.75%.

[0041] In one embodiment, the urea is mixed and melted with the calcium source and t...

Embodiment 1

[0051] The preparation method of the calcium-enriched compound fertilizer of embodiment 1 may further comprise the steps:

[0052]The dilute urine with a temperature of 80°C and a concentration of 80wt% from the urea workshop is pumped to the urea evaporation device on the prilling tower, and the urine is obtained through evaporation and concentration. The mass concentration of the urine is 99.75%; the urine enters The mixing tank of the pulping device on the tower is mixed with ammoniated calcium nitrate and potassium chloride solution in a weight ratio of 80:15:5; after mixing, it flows into the emulsifier of the pulping device on the tower and mixes evenly to obtain slurry; The slurry is passed into the granulator on the tower for granulation to obtain calcium-rich compound fertilizer with a particle size of 1 mm to 4 mm.

Embodiment 2

[0054] The preparation method of the calcium-enriched compound fertilizer of embodiment 2 may further comprise the steps:

[0055] The dilute urine with a temperature of 80°C and a concentration of 80wt% from the urea workshop is pumped to the urea evaporation device on the prilling tower, and the urine is obtained through evaporation and concentration. The mass concentration of the urine is 99.75%; the urine enters The mixing tank of the pulping device on the tower is mixed with ammoniated calcium nitrate and potassium chloride solution in a weight ratio of 15:75:10; after mixing, it flows into the emulsifier of the pulping device on the tower and mixes evenly to obtain slurry; The slurry is passed into the granulator on the tower for granulation to obtain calcium-rich compound fertilizer with a particle size of 1 mm to 4 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com