Automatic packing machine of fruit paper bags

An automatic packaging machine and fruit technology, applied in packaging, food packaging, transportation packaging, etc., can solve the problems of bags with many stains, only manual packaging, and poor appearance, so as to improve the aesthetics and grades, and improve the packaging production. Efficiency, the effect of realizing automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

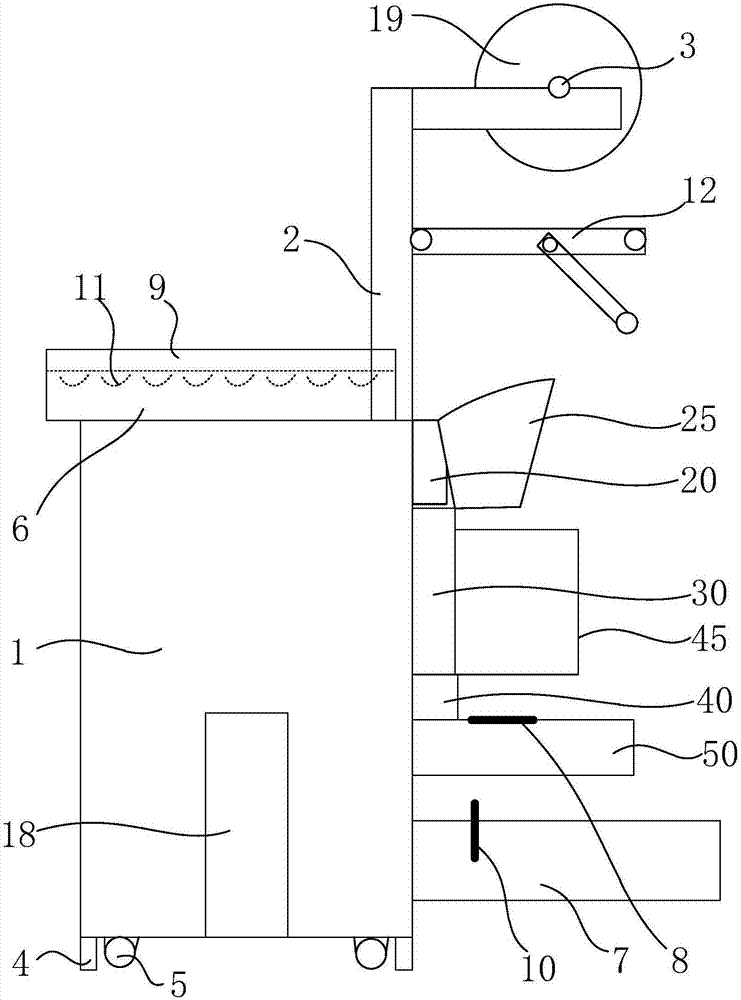

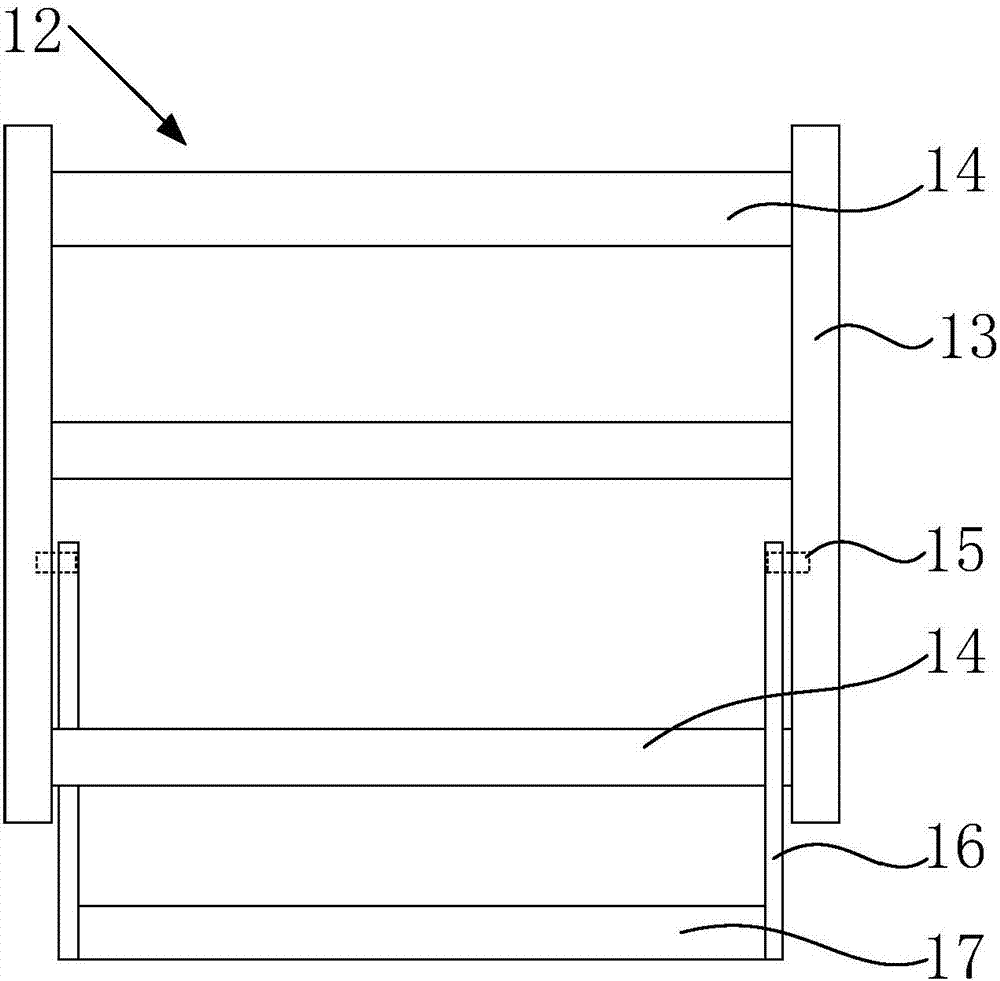

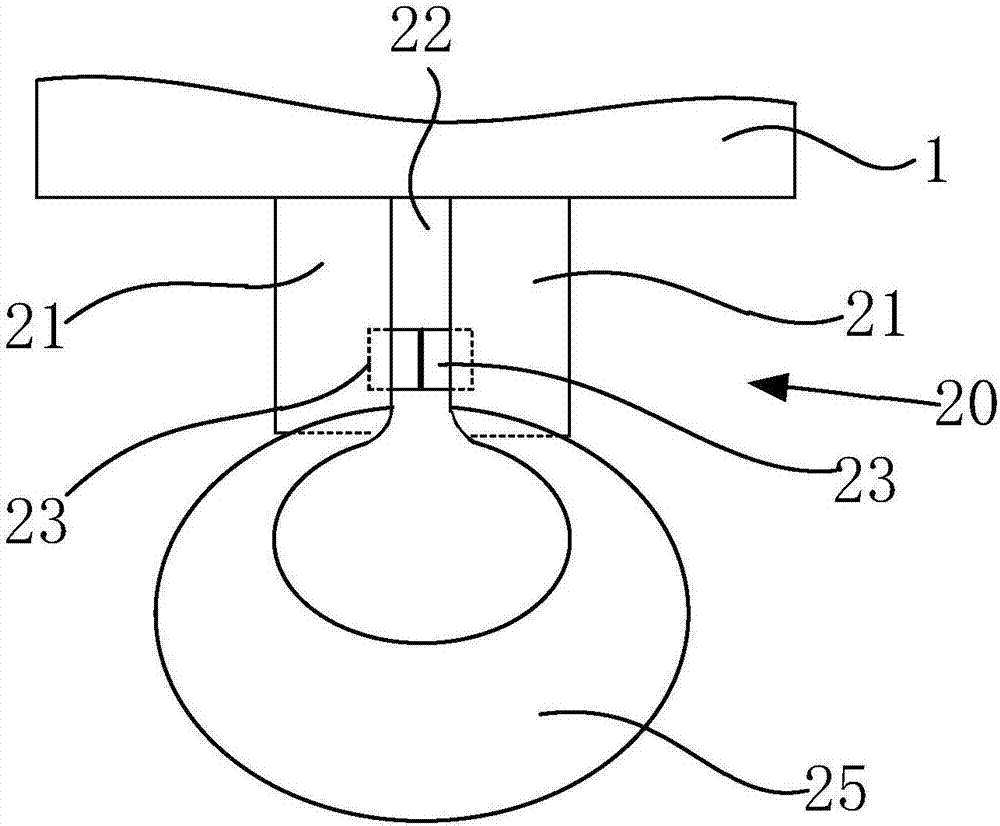

[0032] like Figure 1 to Figure 6 As shown, the fruit paper bag automatic packaging machine includes a frame 1 with a table top on the upper part, a paper feeding support 2 arranged on the frame, and a paper feeding roller 3 arranged on the upper part of the paper feeding support for placing the wrapping paper rolls. The paper feeding mechanism 12 under the paper feeding roller on the paper feeding bracket, the paper collecting frame 20 located below the paper feeding mechanism on the frame, and the tapered paper collecting bucket 25 installed on the paper collecting frame and connected to the frame And the side heat sealing mechanism 30 located at the lower part of the paper gathering frame, the paper puller 40 arranged at the lower part of the side heat sealing mechanism, and the side heat sealing mechanism are arranged side by side on the lower part of the paper gathering frame and opposite to the paper collecting bucket. The end heat-sealing mechanism 50, which is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com