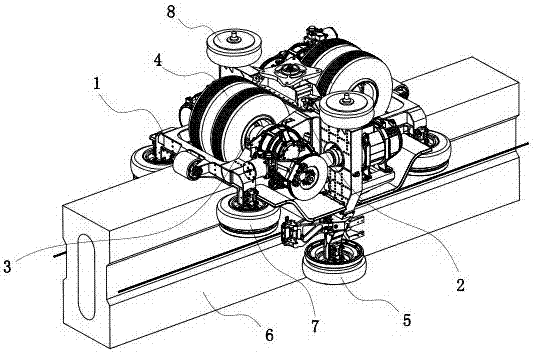

Backbone type double-axle power bogie for straddle type monorail vehicle

A straddle-type monorail, power bogie technology, applied in bogies, railway car body parts, transportation and packaging, etc., can solve the problems of high maintenance costs, high flatness rate of rubber running tires, and high operating costs, reducing the later stage. The effect of maintenance cost, reduction of vertical passage section, and improvement of operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

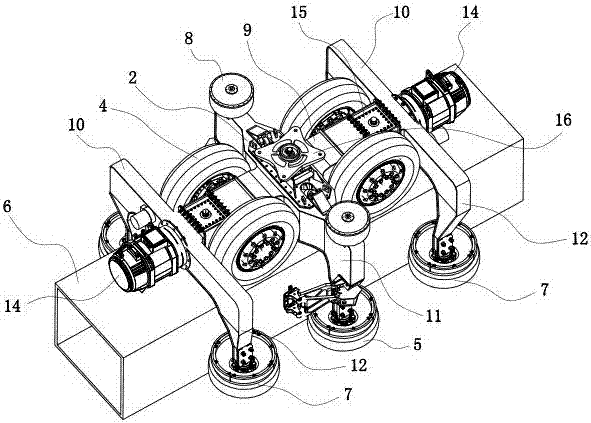

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

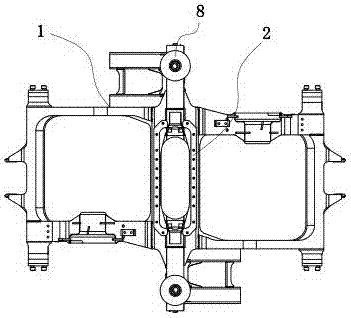

[0021] See attached Figures 3 to 6 , the spine type double-axle power bogie for a straddle-type monorail vehicle in the figure includes a central traction device installation beam 2; wherein: a central traction device installation beam 2 is provided with a Backbone 9, the two ends of this backbone 9 are provided with the guide wheel installation beam 10 that is integrated with backbone 9;

[0022] The two ends of the central traction device installation beam 2 are provided with the stabilizing wheel support arm 11 integrated with the central traction device installation beam 2, and the two ends of the guide wheel installation beam 10 are provided with the guide wheel support arm integrated with the guide wheel installation beam 10 12;

[0023] The central traction device installation beam 2, the spine 9 and the two guide wheel installation beams 10 form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com