Fault-tolerant control system and method for manipulator arm actuator based on double-layer structure

A double-layer structure, fault-tolerant control technology, applied in general control systems, control/adjustment systems, test/monitoring control systems, etc. Linearity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to understand the present invention more intuitively, a detailed description of the present invention is given in conjunction with the accompanying drawings.

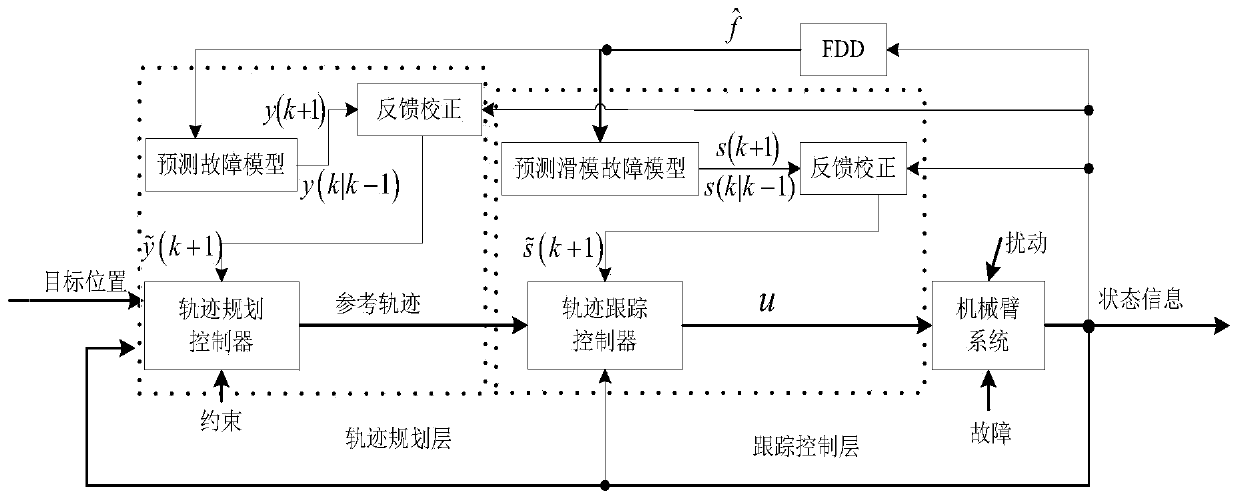

[0070] Such as figure 1 As shown, the present invention is based on the double-layer structure of the manipulator actuator fault-tolerant control system, which uses Taylor series expansion to establish a discrete fault model of the manipulator actuator under the constant deviation fault of the actuator, so as to reduce the amount of calculation and improve the calculation efficiency , to improve real-time performance.

[0071] The fault-tolerant controller of the manipulator includes a trajectory planning layer and a tracking control layer. Information is exchanged between the two layers. According to the different control objectives of each layer, the controller is designed separately, which is more targeted to the problem. Among them, the trajectory planning layer is based on MPC control synthesis Bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com