Conveyer belt test device and method for loading and unloading samples on annular conveyer belt

A technology for test devices and conveyor belts, applied in conveyors, measuring devices, transportation and packaging, etc., can solve the problems of reducing device accuracy, time-consuming loading and unloading samples, and increasing equipment manufacturing costs, so as to reduce the number of disassembly and assembly and maintain accuracy , the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

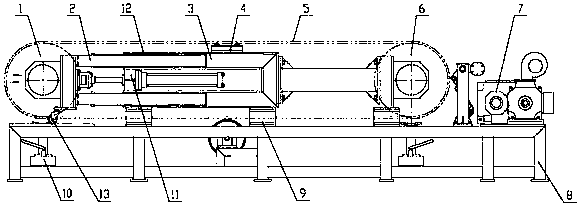

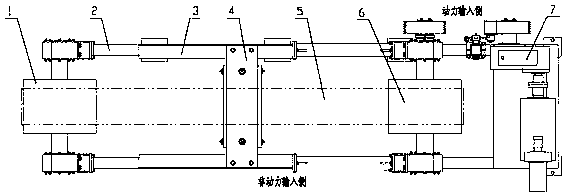

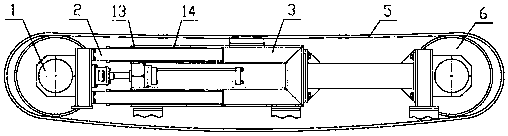

[0031] Such as figure 1 , figure 2 As shown, the conveyor belt energy-saving test device of the present invention includes a driven roller 1 installed on the moving part 2 of the telescopic frame on both sides, and a driving roller installed on the frame fixed part 3 of the telescopic frame on both sides. Drum 6, driving device 7 installed on base 8, conveyor belt sample 5 installed on driving roller 6 and driven roller 1, testing system 4 installed between two straight sections of conveying sample and installed on The driving roller and the hydraulic jack 10 below the driven roller are composed of. The fixed parts 3 of the telescopic brackets on both sides of the base 8 are supported by three pads 9, and the driving roller 6 is driven by the driving device 7 to rotate at a certain speed, and the rotating speed of the driving roller 6 is adjustable; The moving part 2 of the support extends or retracts along the linear slide rail 12, so that the distance between the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com