Device and method for detecting bearing capacity of unilateral type tunnel fan support structure

A technology of supporting structure and detection device, which is applied in the testing of machine/structural components, measuring device, elasticity testing, etc., can solve problems such as test method regulations, and achieve the effects of short test time, simple structure and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

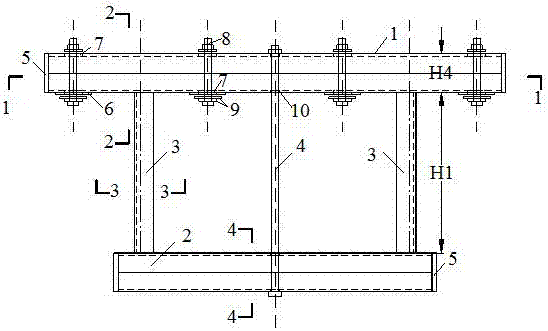

[0032] Introduce technical solution of the present invention in detail below in conjunction with accompanying drawing

[0033] Such as Figure 1-9 As shown, a single-sided tunnel fan support structure bearing capacity testing device includes a Type I test frame and a Type II test frame. The Type I test frame includes an upper beam 1, a lower beam 2, a connecting column 3 and a long screw rod 4. The beam 1 is connected to the lower beam 2 through the connecting column 3, and the upper beam 1 and the lower beam 2 are welded with double-leg channel steel to form a mouth shape. The upper beam is provided with a number of oval through holes 7 penetrating up and down, and high-strength bolts 8 The elliptical through hole 7 is connected to the U-shaped groove on the fan base; the lower beam 2 is in contact with the bottom of the hollow jack and bears the downward reaction force; the Type II test frame includes a beam 11 and a column leg 12, and the beam 11 is composed The channel st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com