U-shaped laser surface microscopic carving overlapping curve air cylinder sleeve and preparation method thereof

A cylinder liner and mesh technology, which is applied in the field of U-shaped laser surface micro-engraved mesh cylinder liner and its preparation, can solve the problems of poor mesh consistency and poor effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

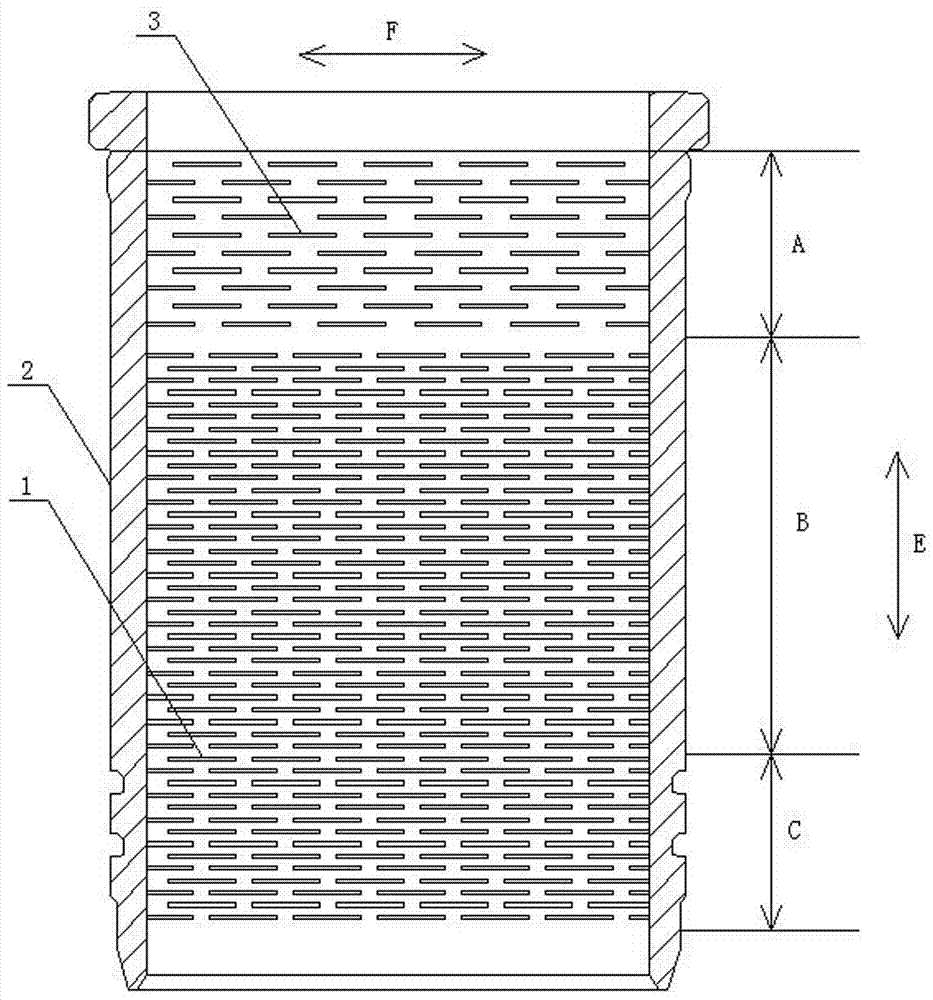

[0021] Such as figure 1 As shown, a U-shaped laser surface micro-engraved reticulated cylinder liner includes a cylinder liner 2. According to the degree of friction and wear, the cylinder liner 2 is divided into A zone, B zone and C zone sequentially from top to bottom, wherein A zone friction , the degree of wear is the largest, the degree of friction and wear in area C is next, and the degree of friction and wear in area B is the smallest. On the inner wall of area A, along the axial direction E of the cylinder liner 2, there are evenly arranged multi-layer first anilox rings, and each layer The first anilox ring includes a plurality of first U-shaped anilox grooves 3 evenly arranged around the circumferential direction F of the cylinder liner 2, and multiple layers of second anilox grooves are uniformly arranged along the axial direction E of the cylinder liner 2 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com