Round sewage gate

A gate, circular technology, applied in the field of sewage treatment, can solve the problems of rework, water seepage of the drainage gate, time-consuming and other problems, and achieve the effect of reducing the probability of water seepage, simplifying the installation process, and shortening the installation period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

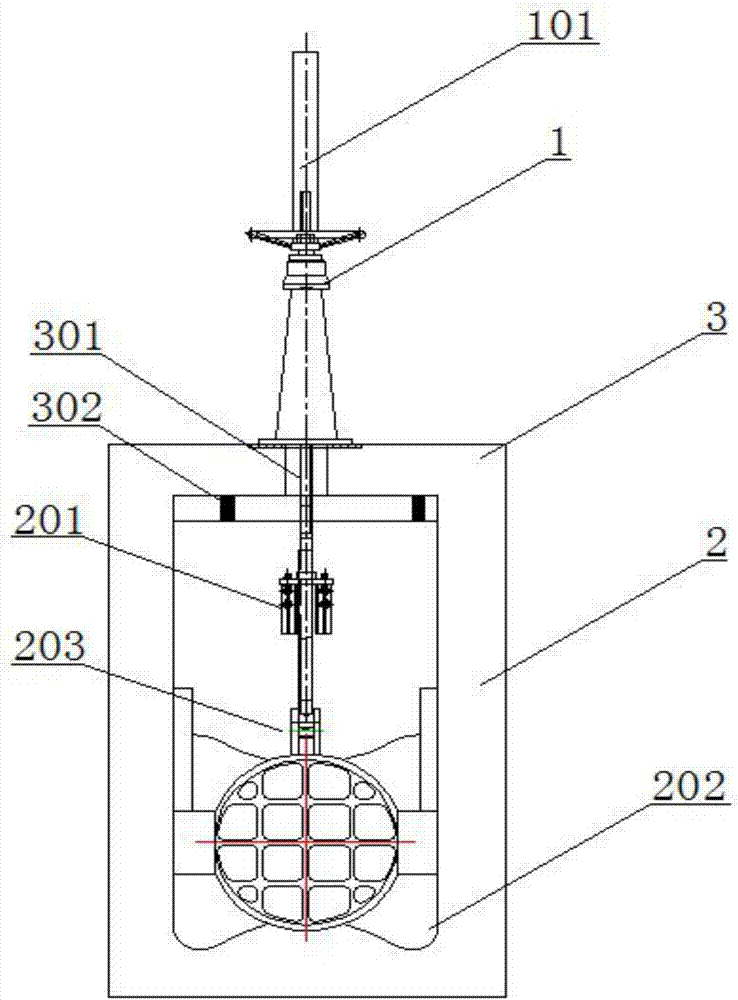

[0020] like figure 1 As shown, a sewage circular gate includes a hoist beam 3, a steel structure screw hole 301 is provided in the middle of the hoist beam 3, and embedded bolts 302 are provided on both sides of the steel structure screw hole 301. The hoist 1 is arranged on the hoist beam 3, the hoist 1 adopts a screw hoist, and the hoist 1 is fixed on the hoist beam 3 by embedded bolts 302.

[0021] A steel structure gate body 2 is provided under the hoist girder 3, and a square drain 201 is provided in the center of the steel structure gate body 2. The steel structure gate body 2 is provided with vertical chute on both sides of the drain 201, and the cast iron gate 4 for closing the sliding connection of the drain 201 is arranged in the chute. The screw 101 of the hoist 1 passes through the steel structure screw hole 301, and the end of the screw 101 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com