Double-shaft swinging and rotating mechanism based on driving gear ring structure

A transmission gear and gear shaft technology, which is applied in the field of electric control technology and aerodynamics, can solve the problems of increased servo mechanism volume, reduced system reliability, and increased maintenance costs, so as to improve reliability, work performance, and work Effects of Environmental Improvement, Mass and Inertia Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

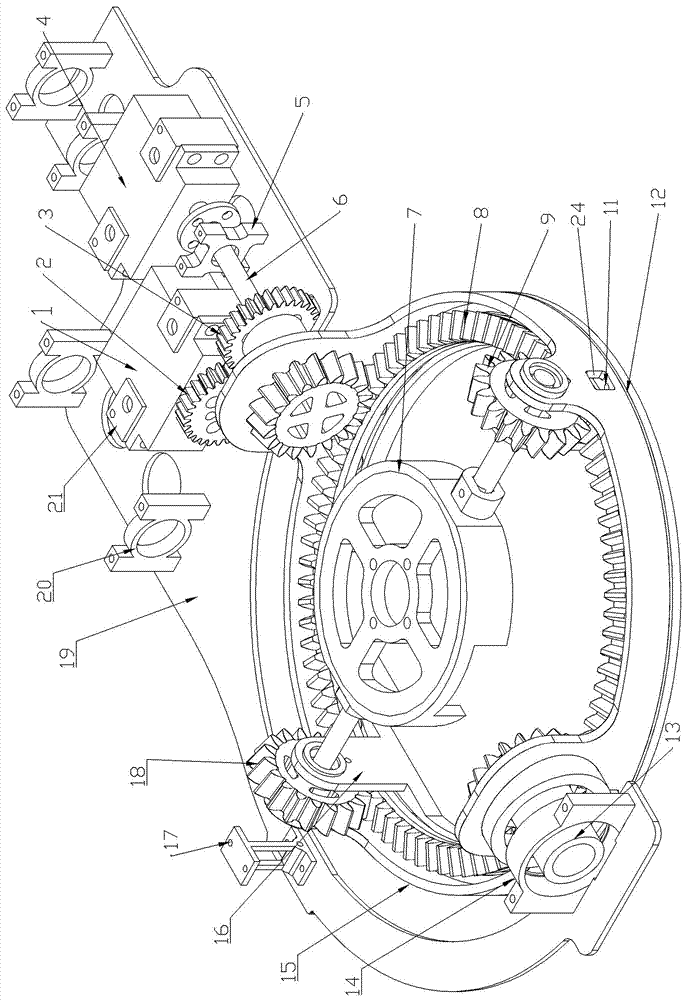

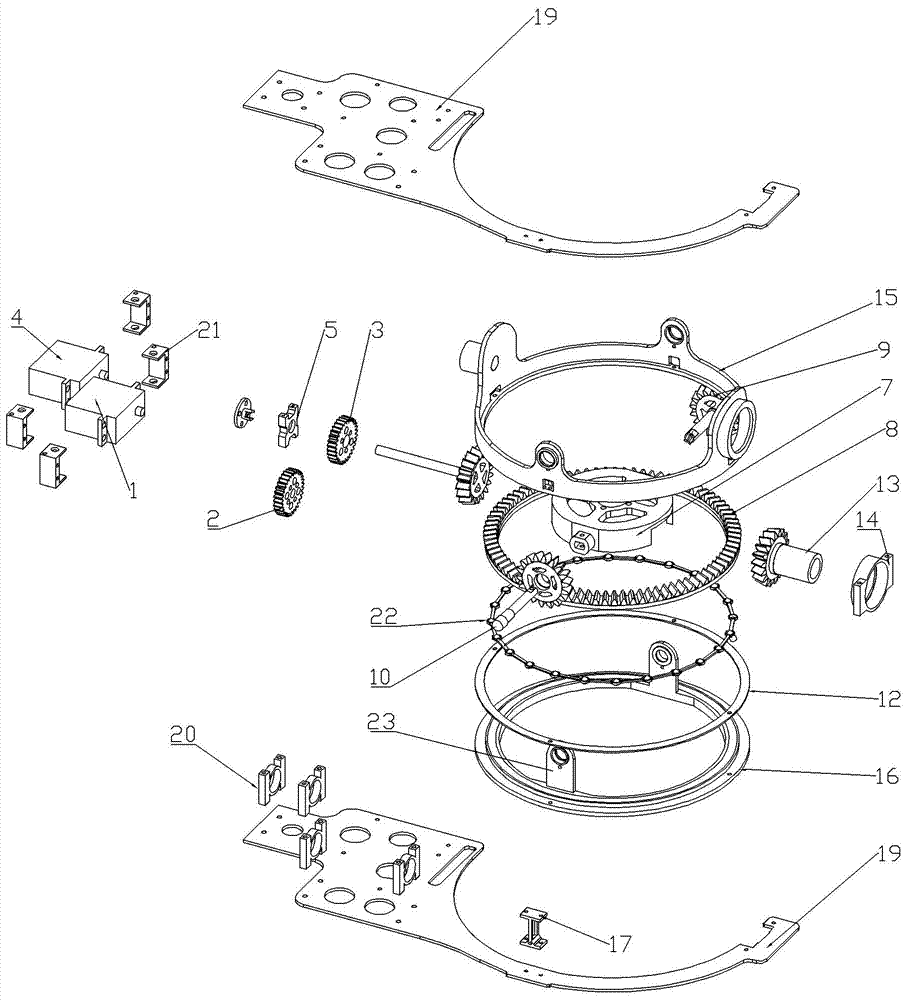

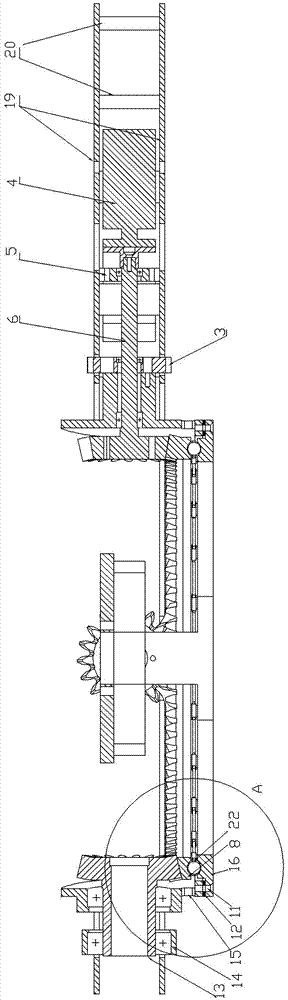

[0031] As shown in the figure, the present invention includes a first servo motor 1, a second servo motor, a first cylindrical gear 2, a first bevel gear, a second cylindrical gear 3 and a housing, and a bevel gear ring 8 is arranged in the housing, and the housing A third bevel gear 18 is arranged on it.

[0032] The center of the first spur gear 2 is connected with the rotating shaft of the first servo motor 1 , the central shaft of the second spur gear 3 is fixedly connected with the housing, and the first spur gear 2 meshes with the second spur gear 3 .

[0033] The first bevel gear shaft 6 is connected to the rotating shaft of the second servo motor 4, and the first bevel gear shaft 6 passes through the central axis of the second spur gear 3 and is connected to the center of the first bevel gear on the housing.

[0034] Both the first bevel gear and the third bevel gear mesh with the bevel gear ring 8 , and the third bevel gear shaft is connected with the engine base 7 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com