Industrial continuous ore crushing device

A crushing device, industrial technology, applied in solid separation, filter screen, grid, etc., can solve the problems of difficult maintenance, large volume, difficult to move, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

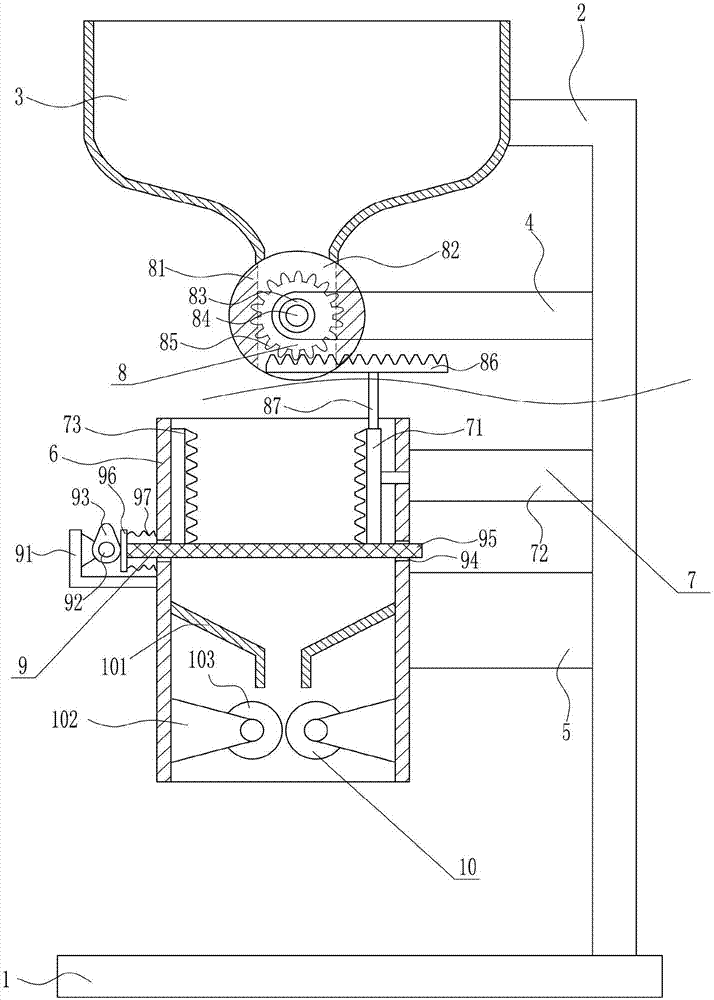

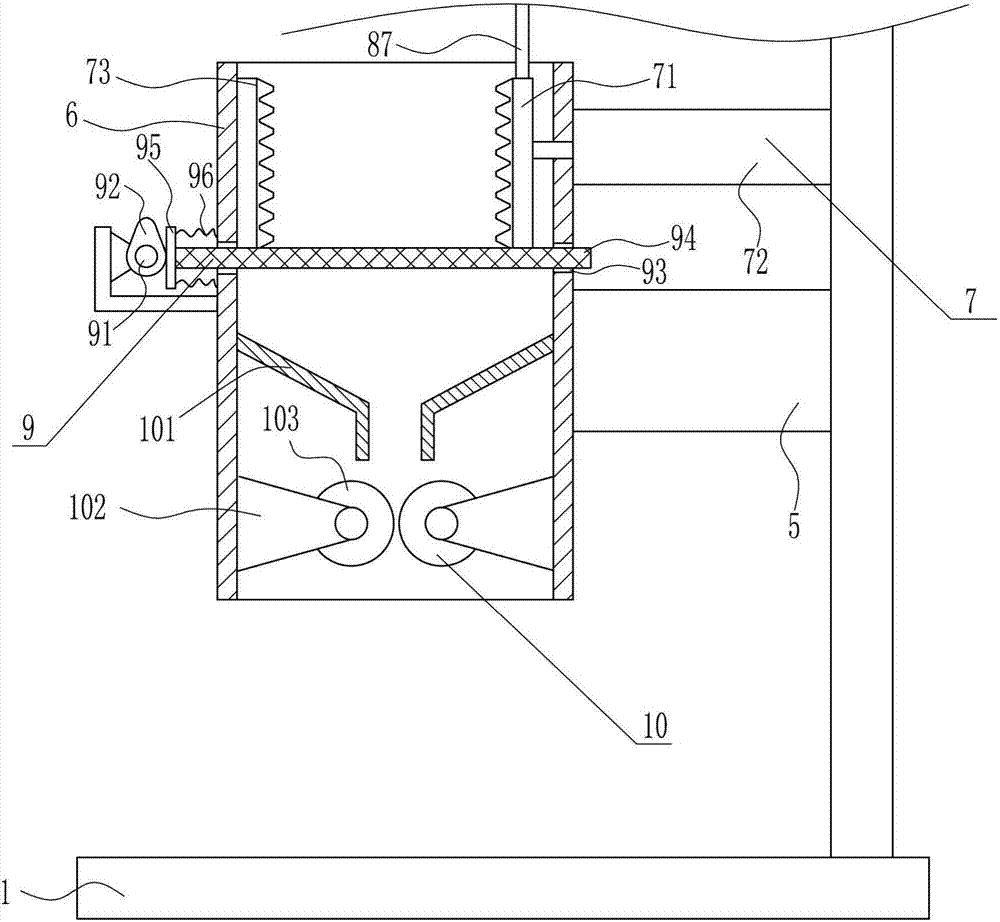

[0027] An industrial ore continuous crushing device, such as Figure 1-2 As shown, it includes a bottom plate 1, an L-shaped bracket 2, a feed hopper 3, a first pole 4, a second pole 5, a crushing cylinder 6, a crushing device 7, a feeding device 8, a screening device 9 and a crushing device 10 The right side of the top of the bottom plate 1 is connected with an L-shaped bracket 2 by means of bolt connection, the top of the L-shaped bracket 2 is provided with a feed hopper 3, and the inner side of the L-shaped bracket 2 is provided with a first pole 4 and a second pole 5, the second A rod 4 is located above the second rod 5, the left end of the first rod 4 is provided with a feeding device 8, and a crushing tube 6 is provided directly below the feeding device 8, and the right end of the crushing tube 6 is connected to the second rod. The left end of 5 is connected, and the crushing device 7 is arranged on the inner upper part of the crushing cylinder 6, and the screening devic...

Embodiment 2

[0029] An industrial ore continuous crushing device, such as Figure 1-2 As shown, it includes a bottom plate 1, an L-shaped bracket 2, a feed hopper 3, a first pole 4, a second pole 5, a crushing cylinder 6, a crushing device 7, a feeding device 8, a screening device 9 and a crushing device 10 The right side of the top of the bottom plate 1 is connected with an L-shaped bracket 2 by means of bolt connection, the top of the L-shaped bracket 2 is provided with a feed hopper 3, and the inner side of the L-shaped bracket 2 is provided with a first pole 4 and a second pole 5, the second A rod 4 is located above the second rod 5, the left end of the first rod 4 is provided with a feeding device 8, and a crushing tube 6 is provided directly below the feeding device 8, and the right end of the crushing tube 6 is connected to the second rod. The left end of 5 is connected, and the crushing device 7 is arranged on the inner upper part of the crushing cylinder 6, and the screening devic...

Embodiment 3

[0032] An industrial ore continuous crushing device, such as Figure 1-2As shown, it includes a bottom plate 1, an L-shaped bracket 2, a feed hopper 3, a first pole 4, a second pole 5, a crushing cylinder 6, a crushing device 7, a feeding device 8, a screening device 9 and a crushing device 10 The right side of the top of the bottom plate 1 is connected with an L-shaped bracket 2 by means of bolt connection, the top of the L-shaped bracket 2 is provided with a feed hopper 3, and the inner side of the L-shaped bracket 2 is provided with a first pole 4 and a second pole 5, the second A rod 4 is located above the second rod 5, the left end of the first rod 4 is provided with a feeding device 8, and a crushing tube 6 is provided directly below the feeding device 8, and the right end of the crushing tube 6 is connected to the second rod. The left end of 5 is connected, and the crushing device 7 is arranged on the inner upper part of the crushing cylinder 6, and the screening device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com