Hybrid modules for motor vehicles

A motor vehicle and hybrid technology, which is applied in the direction of motor vehicles, hybrid vehicles, mechanical drive clutches, etc., can solve the problems of unfavorable amplitude and impaired comfort, and achieve the effect of compact structure and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

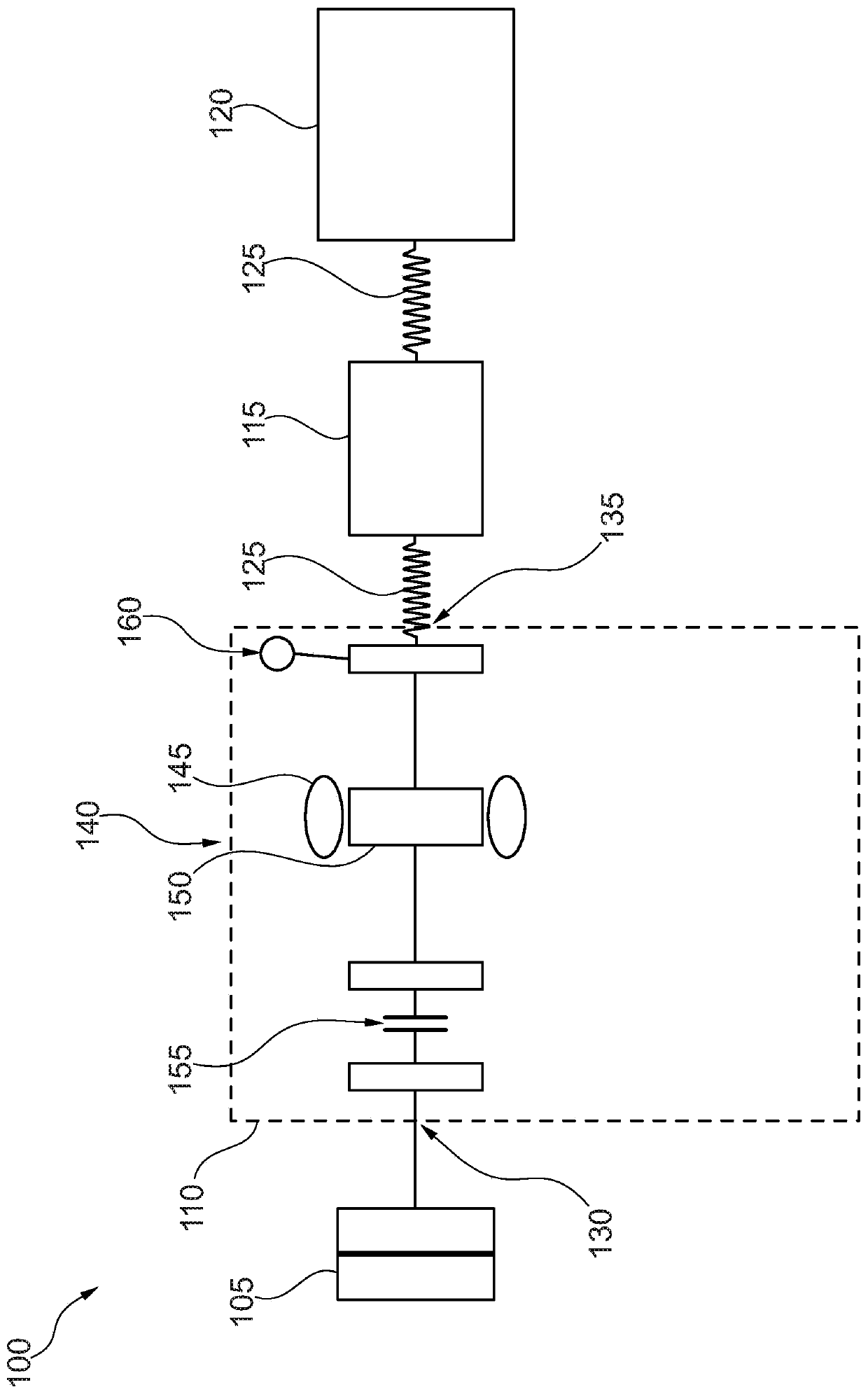

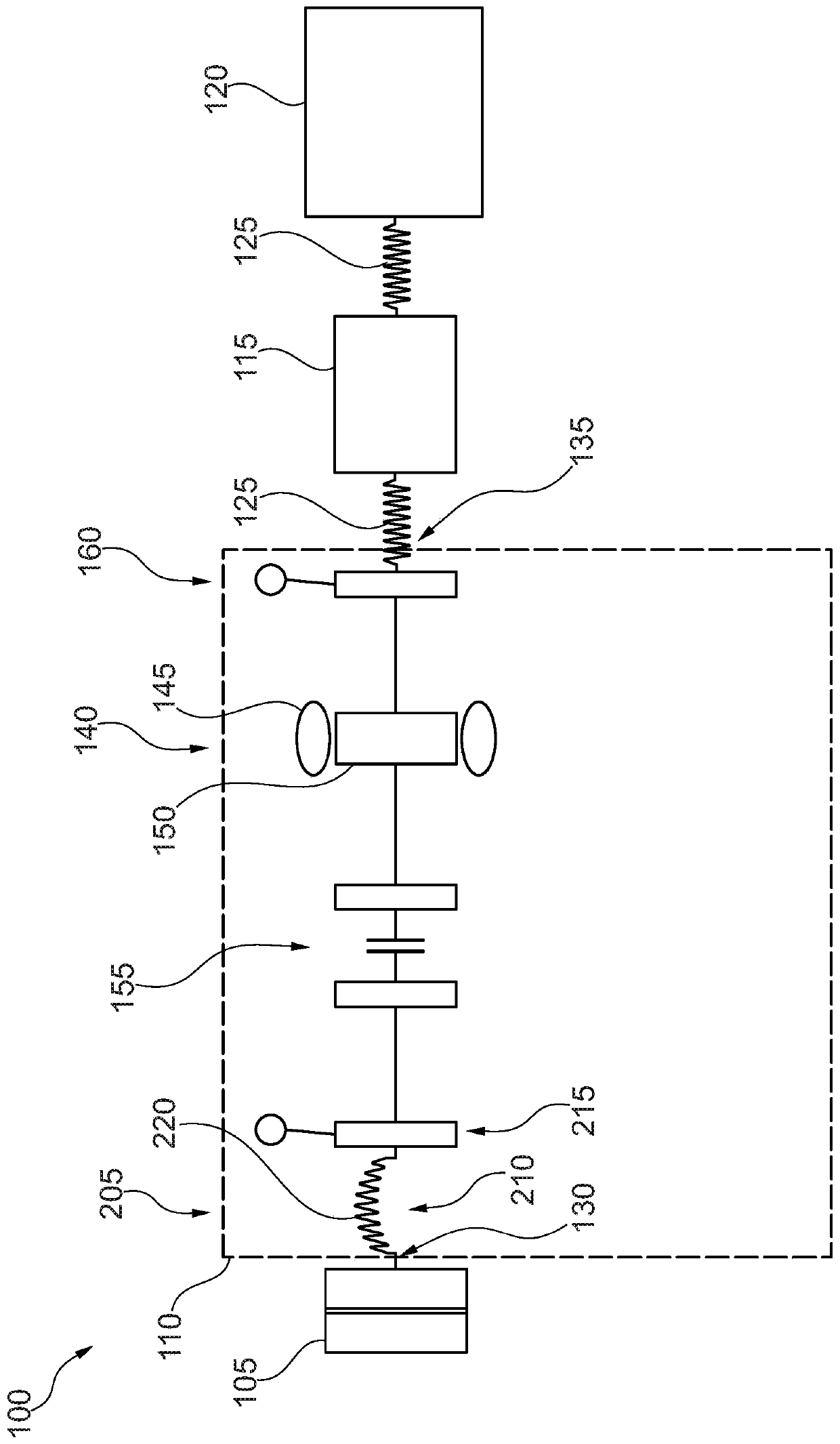

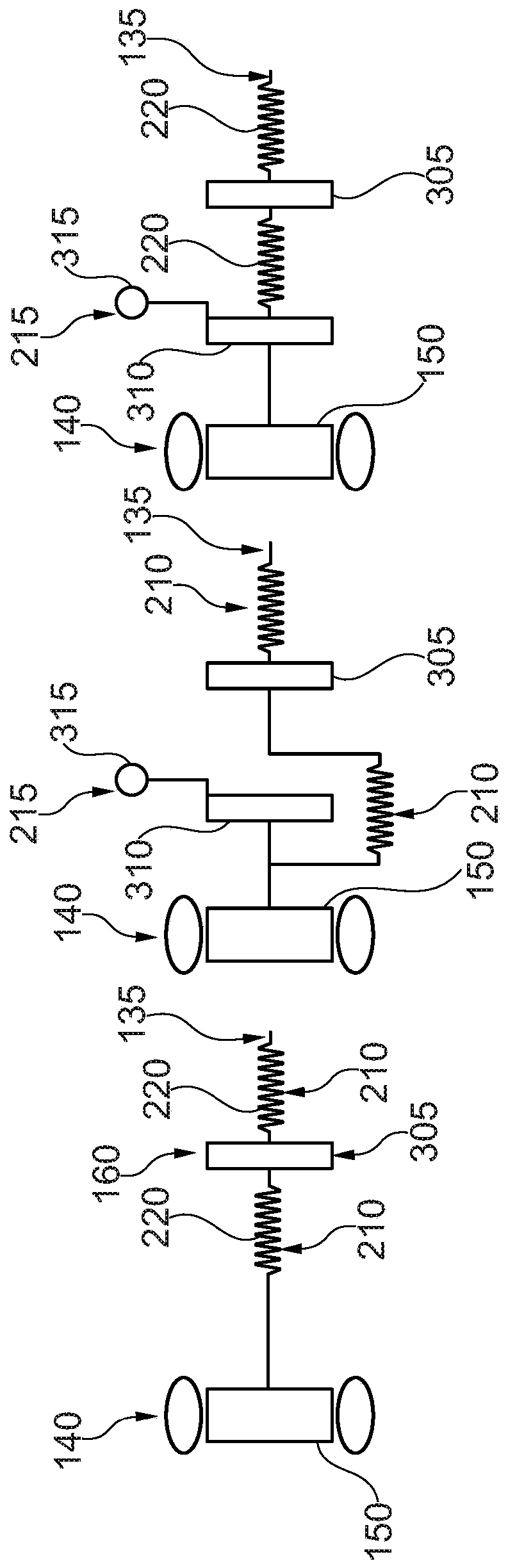

[0029] figure 1 A drive train 100 is shown, for example a drive train in a motor vehicle. Drivetrain 100 includes internal combustion engine 105 , hybrid module 110 , optional transmission 115 , and drive wheels 120 . Preferably, the transmission 115 is a semi-automatic or fully automatic transmission (such as a dual-clutch transmission), a stepped automatic transmission or a transmission with a continuously variable transmission ratio (Continuous Variable Transmission, CVT). Torsional vibration dampers or torsional vibration dampers 125 can be arranged at various points of drive train 100 , in particular between hybrid module 110 and transmission 115 or between transmission 115 and drive wheels 120 .

[0030] Hybrid module 110 includes an input side 130 for connection to internal combustion engine 105 and an output side 135 for connection to the part of drive train 100 leading to drive wheels 120 . An electric motor 140 having a stator 145 and a rotor 150 is provided as a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com