Squeeze and turn child resistant closure attachment

A technology for child-safe, closed components, applied in the direction of closures, caps, closures, etc., which can solve problems such as difficult alignment of outer parts and inner closure parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

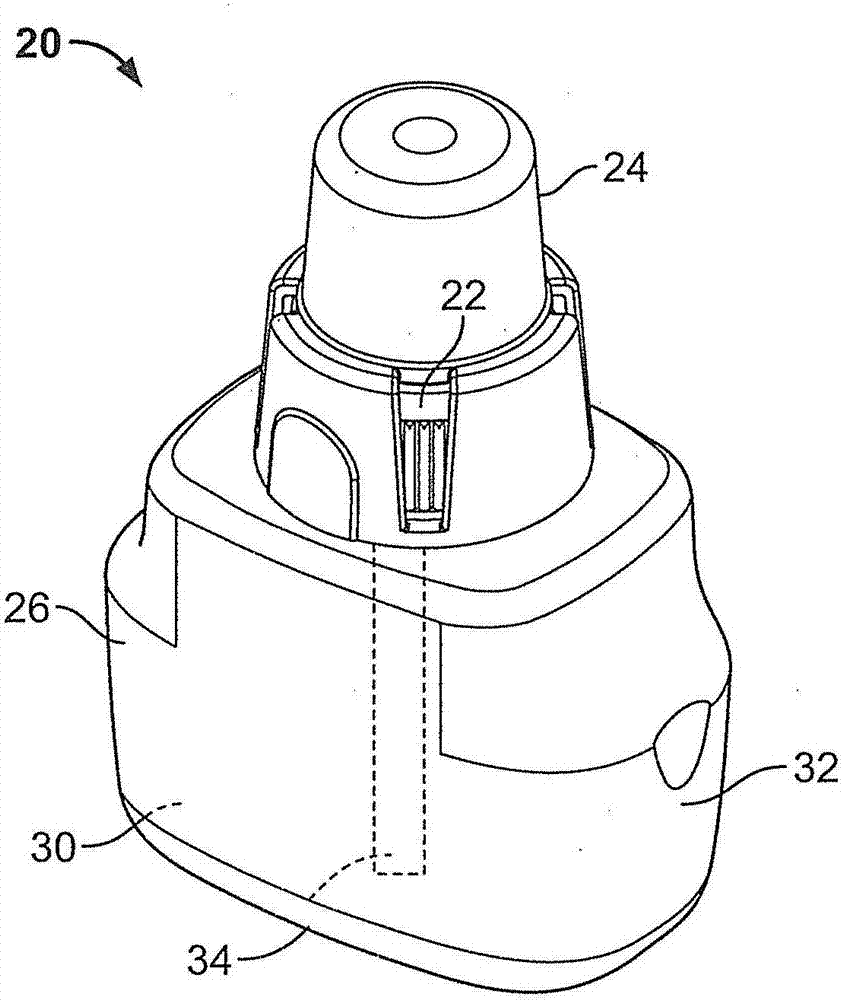

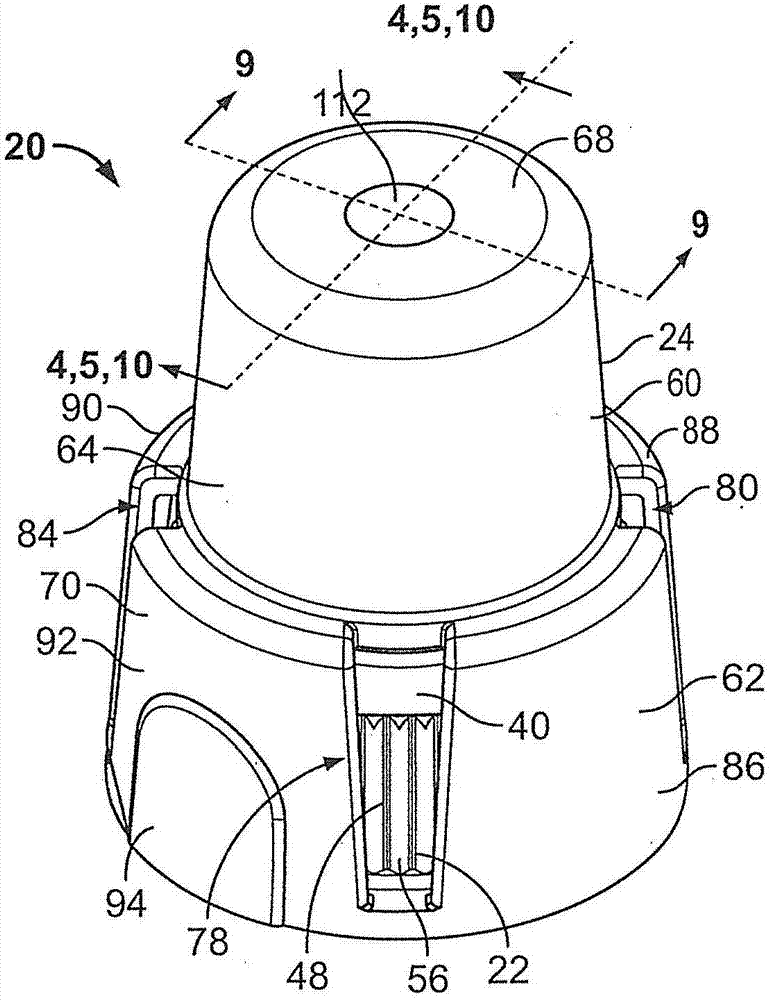

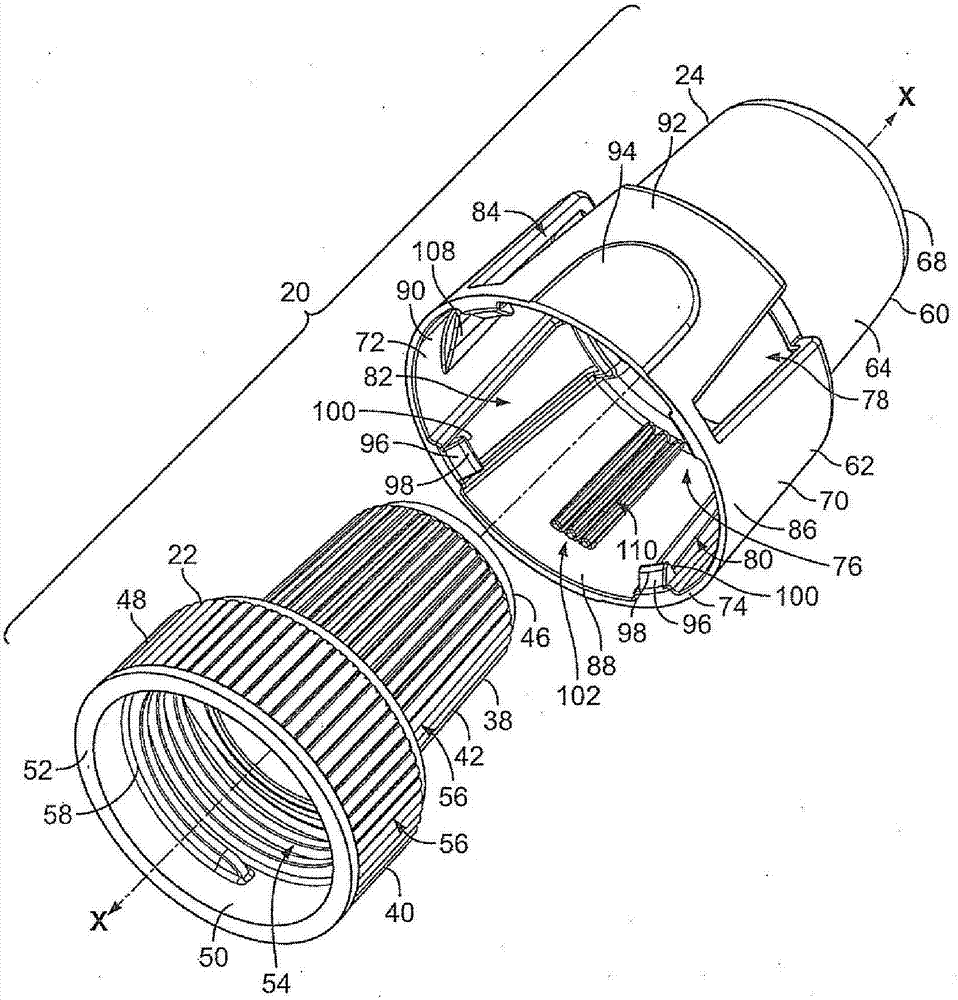

[0025] Figure 1-10 A child resistant cover lock assembly 20 is shown. The cover locking assembly 20 includes an inner cover 22 and an outer locking cover 24 . The cap lock assembly 20 is adapted to be screwed into a container 26 that includes a threaded neck 28 and a volatile liquid 30 disposed within a reservoir 32 . In this embodiment, the container 26 further includes a core 34 and a core adapter 36 mated to the threaded neck 28 (see Figure 4 )Inside. Core 34 extends through reservoir 32 , up through core joint 36 , and finally into inner cap 22 . In order for the wick 34 to wick the volatile liquid 30 out of the container 26, it is preferred that the wick 34 is formed from a conventional wicking material. Suitable wicking materials include porous / sintered plastics such as UHDPE and polypropylene; bonded fibers such as polyester and polypropylene; glass sintered fibers; porous ceramics; carbon fibers; sintered carbon; compressed wood composites ; Bundled or woven nat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap