Fast assembly type ceiling lamp

A chandelier, fast technology, applied in the direction of lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of strengthening the position of solder joints, potential safety hazards of weak welding, and complicated chandelier assembly, etc., to achieve high position Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

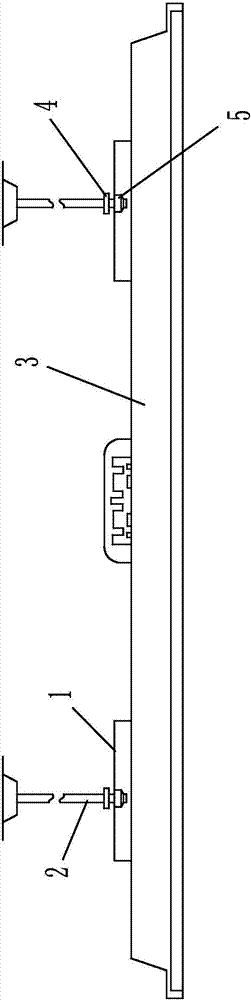

[0021] Embodiment 1: as figure 1 As shown, a quick-install pendant lamp includes a lamp body 3 and a suspender 2. Several lamp stands 1 are arranged on the upper surface of the lamp body. slot, the axis of the boom is provided with a positioning hole, the bottom of the boom is provided with an upper limit nut 4, the boom is detachably connected to the light stand through a limit connector, the limit connector includes a connecting column, and one end of the connecting column is provided with a The diameter of the limit plate is larger than that of the connecting column. The bottom of the limit plate is provided with a lower limit nut 5. The lower limit nut is fixedly connected with the limit plate. The connecting column and the limit plate are connected in one piece. The connection is in the positioning hole of the suspender and is threadedly connected with the suspender, and the diameter of the connecting column matches the width of the fixing groove.

[0022] A lamp holder ...

Embodiment 2

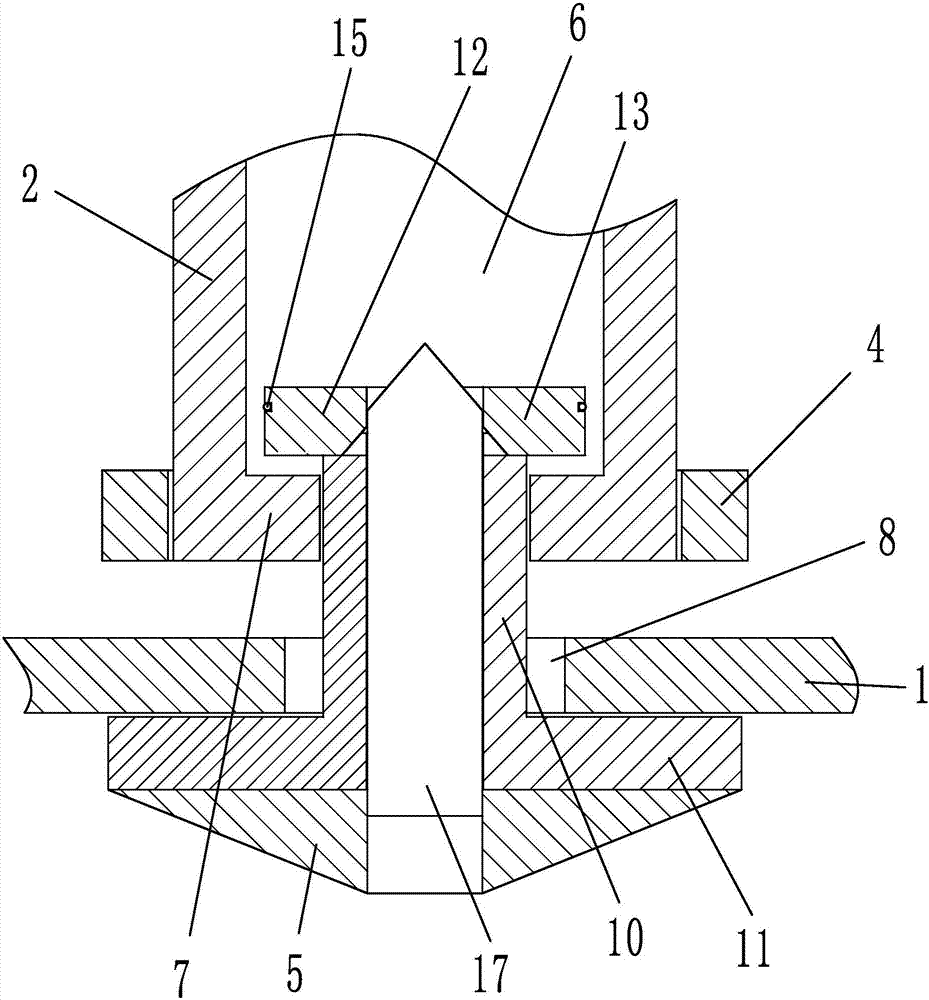

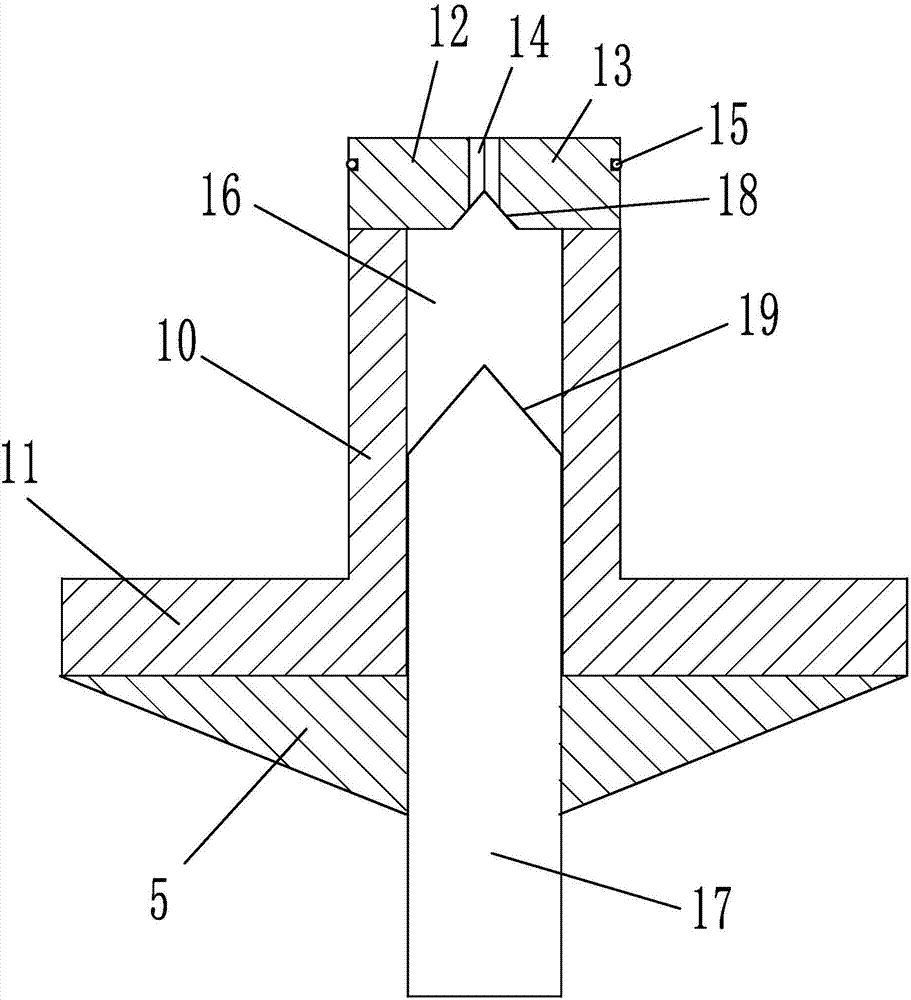

[0023] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as figure 2 , 3 , 4, 5, the bottom of the boom extends to the axial direction with a positioning ring 7, the inner diameter of the positioning ring is smaller than the diameter of the positioning hole; the end of the connecting column 10 away from the limit plate is provided with a ring-shaped turning block, the turning block A fixed groove around the axis of the rotary block is provided on the outer wall of the rotary block, and a tightening ring 15 sleeved on the outside of the rotary block is arranged in the fixed groove. A guide hole 14 is provided at the axis of the rotary block. The rotary block includes a left rotary block 12 and a right rotary block. Block 13, the bottom of left turn block and right turn block are all provided with bump 20, and the end face of connecting column is provided with the chute 21 that matches with bump, and chute is d...

Embodiment 3

[0025] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 2, the difference is that, as Figure 8 As shown, a guide groove 24 is provided at the axis of the sliding chamber, and the guide groove is parallel to the axis direction of the connecting column. A vibrating spring 25 is arranged in the guide groove. The axis of the vibrating spring is parallel to the axis of the connecting column and supports the ball. When the ball is subjected to When the pressure of the left turn block and the right turn block is applied, the vibration spring can push the ball to exert an external force on the bump, and use the external force to resist gravity, avoiding excessive extrusion of the ball by the bump, and further reducing the connection between the left turn block and the right turn block and the connecting column Swipe between. At the same time, when the adjusting column squeezes into the guide hole, the direction of the extrusion force on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com