Rapid mounting method for flexible transmission device of large sintering machine

A technology of flexible transmission and installation methods, which is applied to transmission parts, transmission boxes, mechanical equipment, etc., can solve the problems of inconvenient installation, large weight and volume, complex structure, etc., and achieve the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

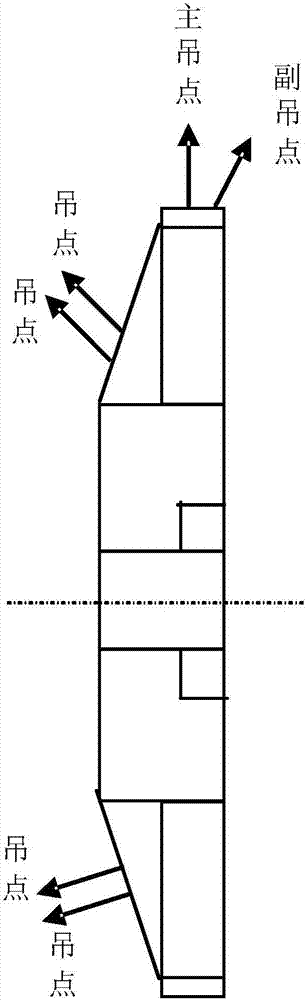

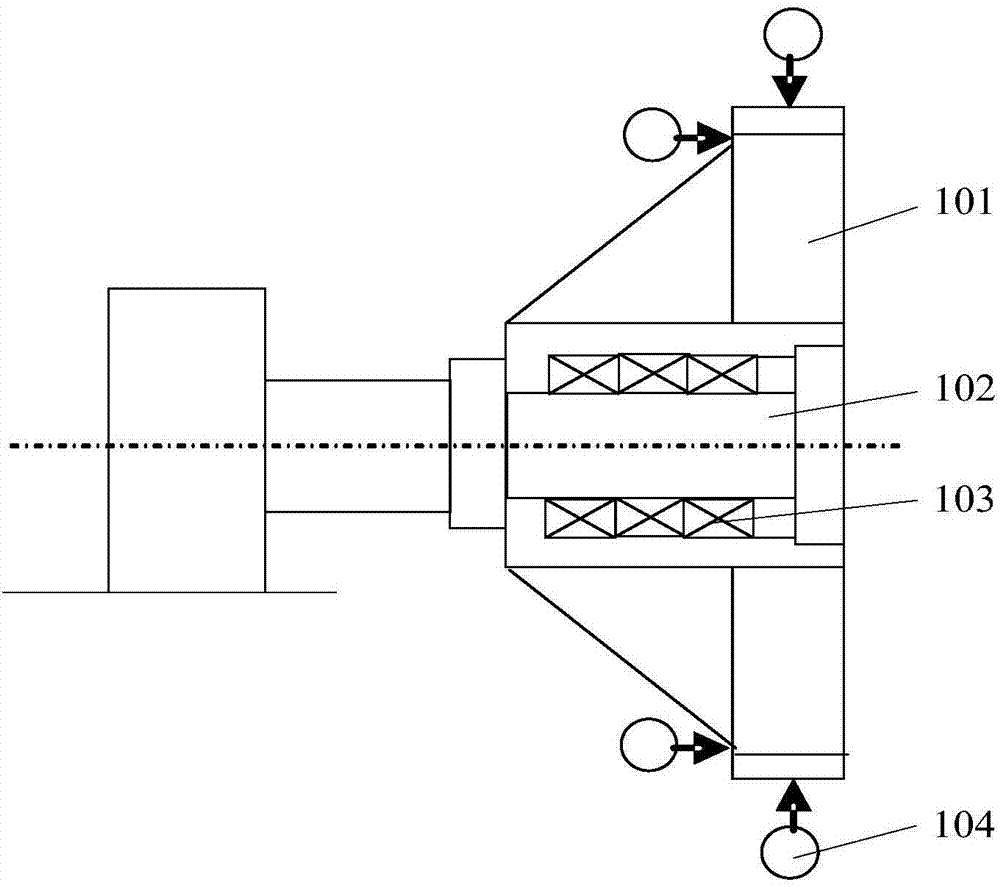

[0051] The process of assembling the large gear to the main shaft in the above step 1) is as follows:

[0052] 1) Clean the journal of the large gear 101 and the main shaft 102 for assembling the large gear 101; 2) Check whether the assembly size tolerance of the mounting hole of the large gear 101 and the main shaft 102 is within the preset fit tolerance range, if so, proceed to the following Step; 3) hoisting the large gear 101 to the above journal of the main shaft 102 .

[0053] Apparently, in the quick installation method provided by the embodiment of the present invention, the large gear 101 is installed to the journal of the main shaft 102 by means of hoisting, so as to avoid impact on the large gear 101 and help protect the end face of the large gear 101 from damage.

[0054] Specifically, the above step 1) is:

[0055] Grinding the burrs and sharp corners of the bull gear 101 and the journal, cleaning the bull gear 101 and the journal, and degreasing the bull gear 10...

Embodiment 2

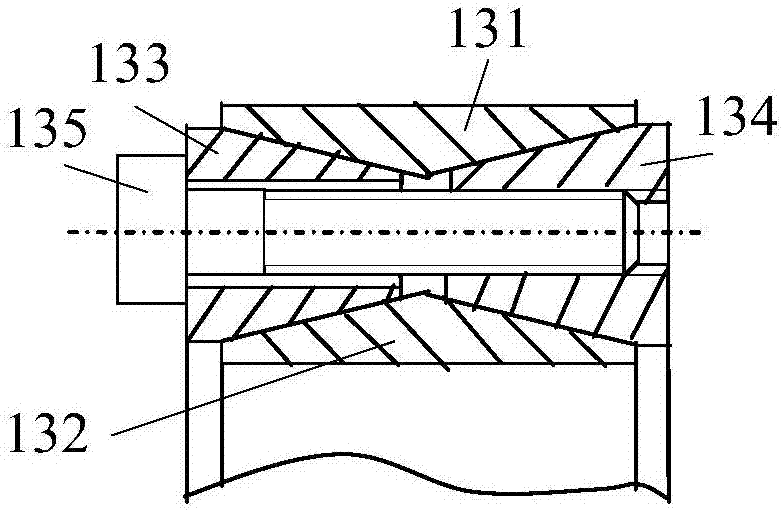

[0071] The step 2) of the quick installation method for the flexible transmission device of the large-scale sintering machine provided by the above embodiment specifically includes:

[0072] 1) Clean the inner ring 132, outer ring 131, front cone ring 133 and rear cone ring 134 of the tension ring 103; 2) assemble each ring of the tension ring 103; 3) set the tension ring 103 on the main shaft 102, And move the tensioning ring 103 to the innermost side of the mounting hole along the main shaft 102; the mounting hole is the annular gap between the main shaft 102 and the large gear 101; 4) Tighten the locking bolt 135 of the tensioning ring 103 so that the locking bolt 135 Reliably connect the above-mentioned front cone ring 133 and rear cone ring 134 .

[0073] In the quick installation method provided by the embodiment of the present invention, the inner ring 132, the outer ring 131, the front cone ring 133 and the rear cone ring 134 of the tension ring 103 are cleaned first, ...

Embodiment 3

[0105] The step 3) of the quick installation method for the large-scale sintering machine flexible transmission device provided in the above embodiment specifically includes:

[0106] 31) Based on the center of the gear wheel 101, determine the elevation of the bearing seat of the torsion bar 108, and the limit deviation of the elevation is 0.5mm;

[0107] 32) Install the torsion bar 108 on the torsion bar bearing seat, and align the torsion bar 108;

[0108] After the alignment, the levelness of the middle position of the torsion bar 108 should be less than 0.5 / 1000.

[0109] Before performing the above step 32), the vertical and horizontal deviation of the central position of the torsion bar 108 should be smaller than the preset limit deviation, and the preset limit deviation is 0.5mm.

[0110] The step 4) of the quick installation method for the large-scale sintering machine flexible transmission device provided in the above embodiment specifically includes:

[0111] 41) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com