Automobile seat headrest unlocking assembly

A technology for car seats and headrests, which is applied to vehicle seats, vehicle parts, special positions of vehicles, etc., and can solve the problem of limiting the stroke of headrest lift and front and rear adjustment, the small range of headrest lift and front and rear adjustment, and the problem of headrest Problems such as limited internal space, to achieve the effect of increased range, good reliability, improved practicability and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

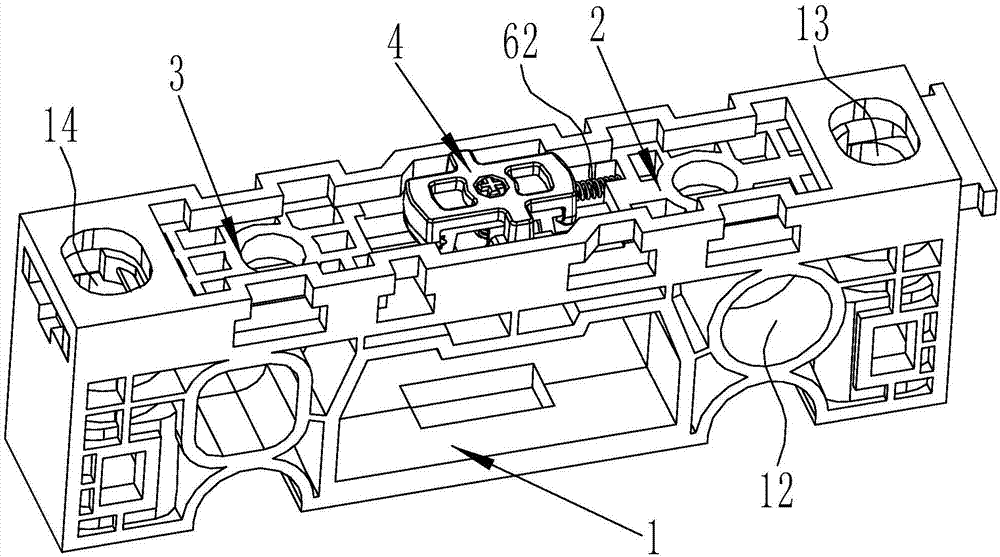

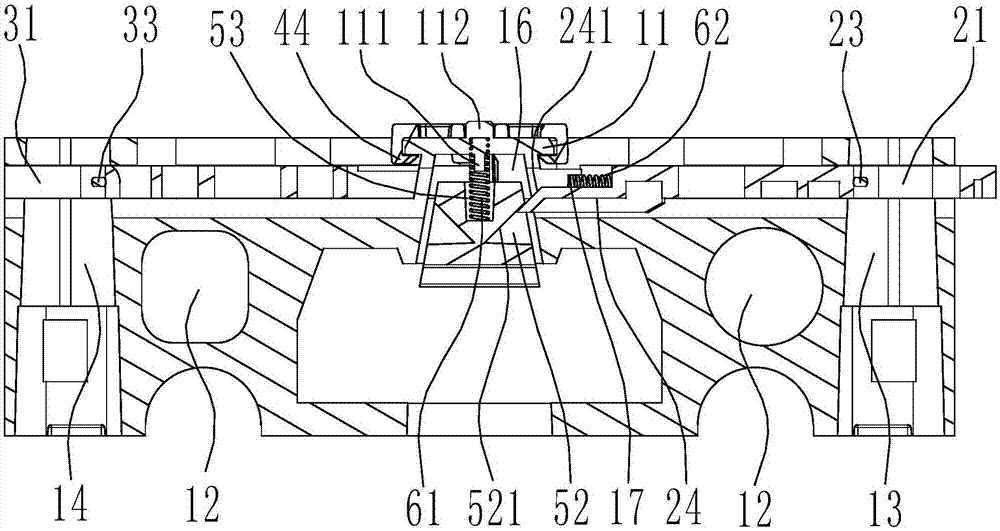

[0027] Such as figure 1 with Figure 5 As shown, a car seat headrest unlocking assembly includes a base body 1, a driving push block 2, a driven push block 3, a rotor 4 and a tab 5, and the base body 1, a driving push block 2, and a driven push block 3 , the rotor 4 and the tongue 5 are all formed as one piece, so as to improve their structural strength and facilitate assembly. The base body 1, the driving push block 2, the driven push block 3, the rotor 4 and the tab 5 all have weight-reducing holes to meet the requirements of light weight of automobiles.

[0028] See Figure 1 ~ Figure 4 with Figure 7 , the base body 1 has a first installation opening 13 and a second installation opening 14 penetrating up and down and two guide holes 12 penetrating front and rear, wherein the headrest rod 8 of the seat headrest respectively passes through the first ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com