Intelligentized machining system

A processing system and performance technology, applied in sorting and other directions, can solve problems such as waste of resources, increased production costs, product performance testing, etc., to avoid program confusion, improve accuracy, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

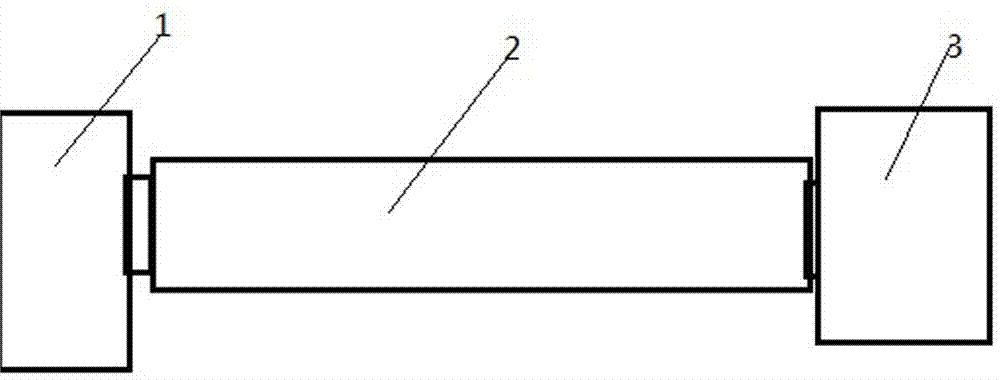

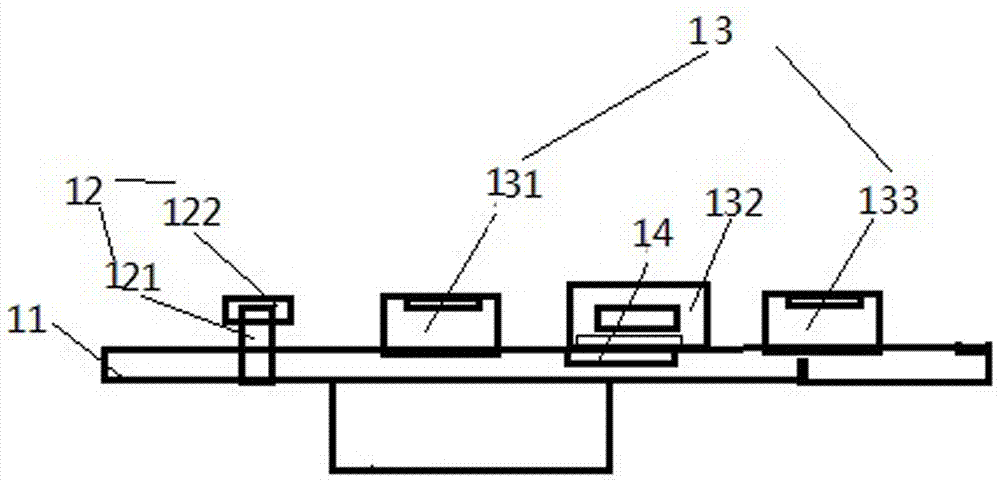

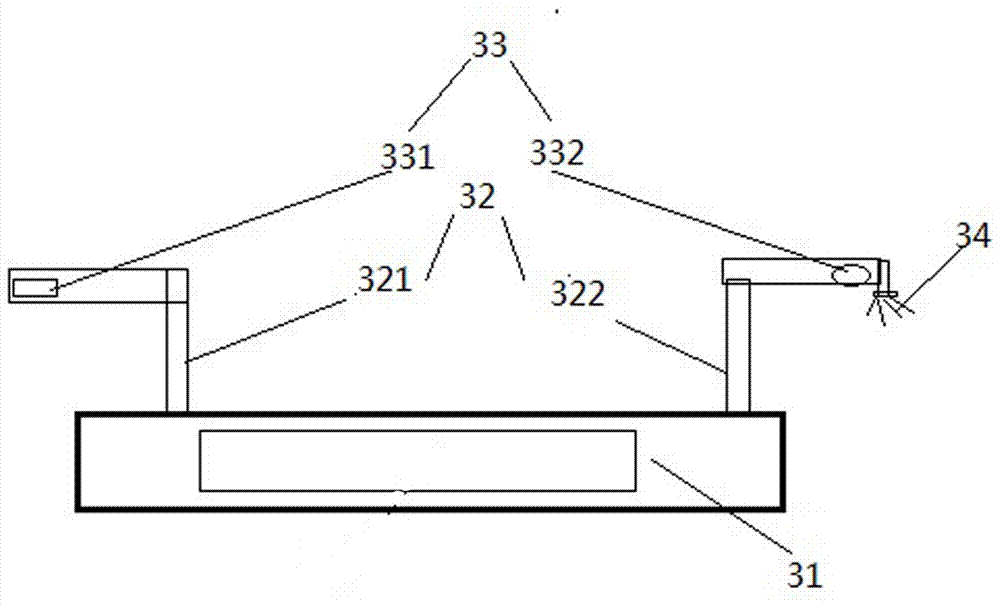

[0030] An intelligent processing system as shown in the figure includes: an automatic feeding mechanism 1, a production line 2 and an automatic unloading mechanism 3, the automatic feeding mechanism 1 and the automatic unloading mechanism 3 are arranged at both ends of the production line 2, so Both the automatic feeding mechanism 1 and the automatic unloading mechanism 3 are connected to the control device of the production line 2, wherein, the automatic feeding mechanism 1 is provided with a transport platform 11, and the transport platform 11 is provided with a group of product placement areas and A position adjustment mechanism 12 for adjusting the position of the product. The position adjustment mechanism 12 is provided with a loading mechanical arm 121, and the loading mechanical arm 121 is arranged on both sides of the transport platform 11, and the loading mechanical arm 121 A feeding manipulator 122 is provided on the top, and a product detection device 13 is provided ...

Embodiment 2

[0043] An intelligent processing system as shown in the figure includes: an automatic feeding mechanism 1, a production line 2 and an automatic unloading mechanism 3, the automatic feeding mechanism 1 and the automatic unloading mechanism 3 are arranged at both ends of the production line 2, so Both the automatic feeding mechanism 1 and the automatic unloading mechanism 3 are connected to the control device of the production line 2, wherein, the automatic feeding mechanism 1 is provided with a transport platform 11, and the transport platform 11 is provided with a group of product placement areas and A position adjustment mechanism 12 for adjusting the position of the product. The position adjustment mechanism 12 is provided with a loading mechanical arm 121, and the loading mechanical arm 121 is arranged on both sides of the transport platform 11, and the loading mechanical arm 121 A feeding manipulator 122 is provided on the top, and a product detection device 13 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com