Rolling machine

A technology of roller compactor and roller, which is applied in grain processing, application, grain depodization, etc., can solve the problems of insufficient rolling, ineffectiveness, and dust pollution of the environment, so as to achieve sufficient rolling, good effect, and high efficiency. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with specific embodiments.

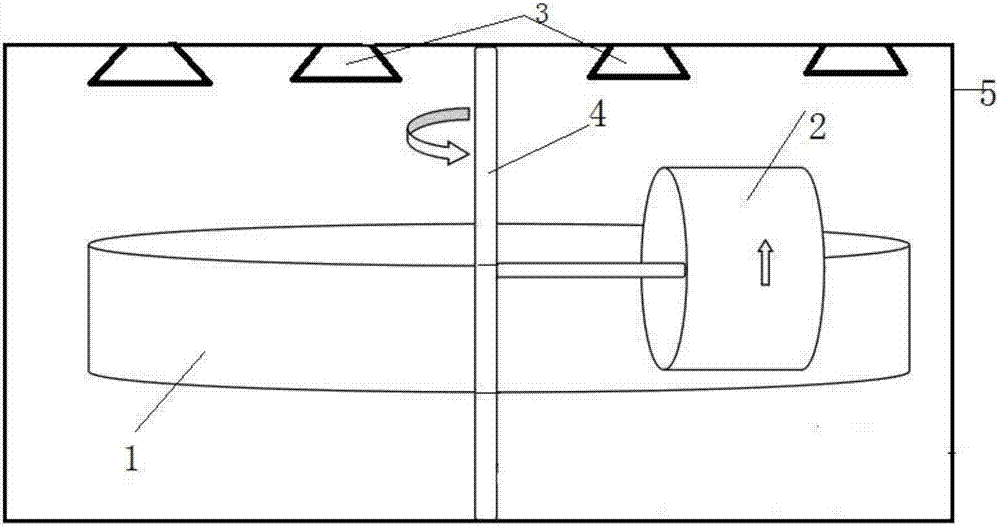

[0014] Such as figure 1 The rolling machine shown includes a disc body 1, a grinding wheel 2, a blower fan 3 and a casing 5, a rotating shaft 4 is arranged in the middle of the disc body 1, and the rolling wheel 2 is installed on the rotating shaft 4; the fan 3 It is installed on the top inside the shell 1; the bottom surface of the disc body 1 is mesh-shaped. Grinding wheel 2 is fixedly installed on the rotating shaft 4 by steel bar. Fan 3 is 4. The casing 5 is a sealing body.

[0015] The size of the mesh aperture on the bottom surface of the disc body is adjusted according to the actual rolling product, but it is enough to allow the blowing air of the fan to pass through the net to achieve the effect of flow and driving. When in use, the fan blows air downward from the upper end of the disc body, so that the rolled product can be tumbling. On the one hand, it can p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com