Composite wire twisting and bending tester

A bending testing machine and composite technology, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, measuring devices, instruments, etc., can solve the problems that cannot meet the accuracy requirements of the detection data and the detection effect is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

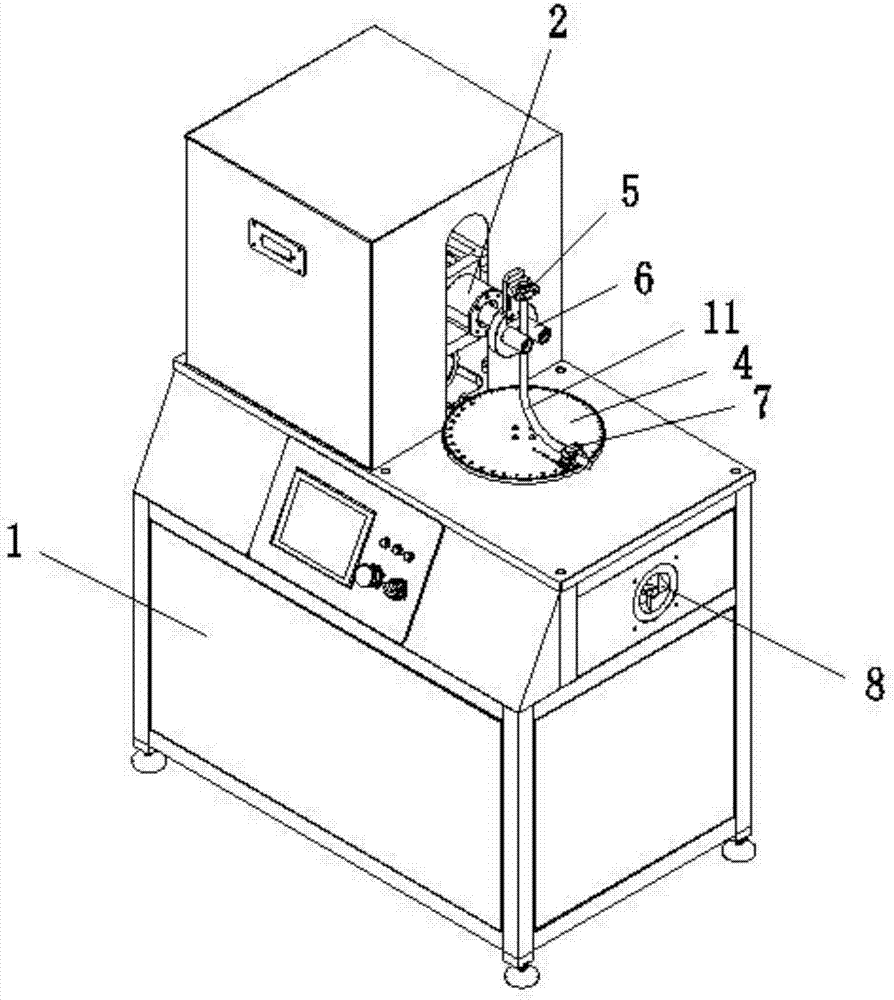

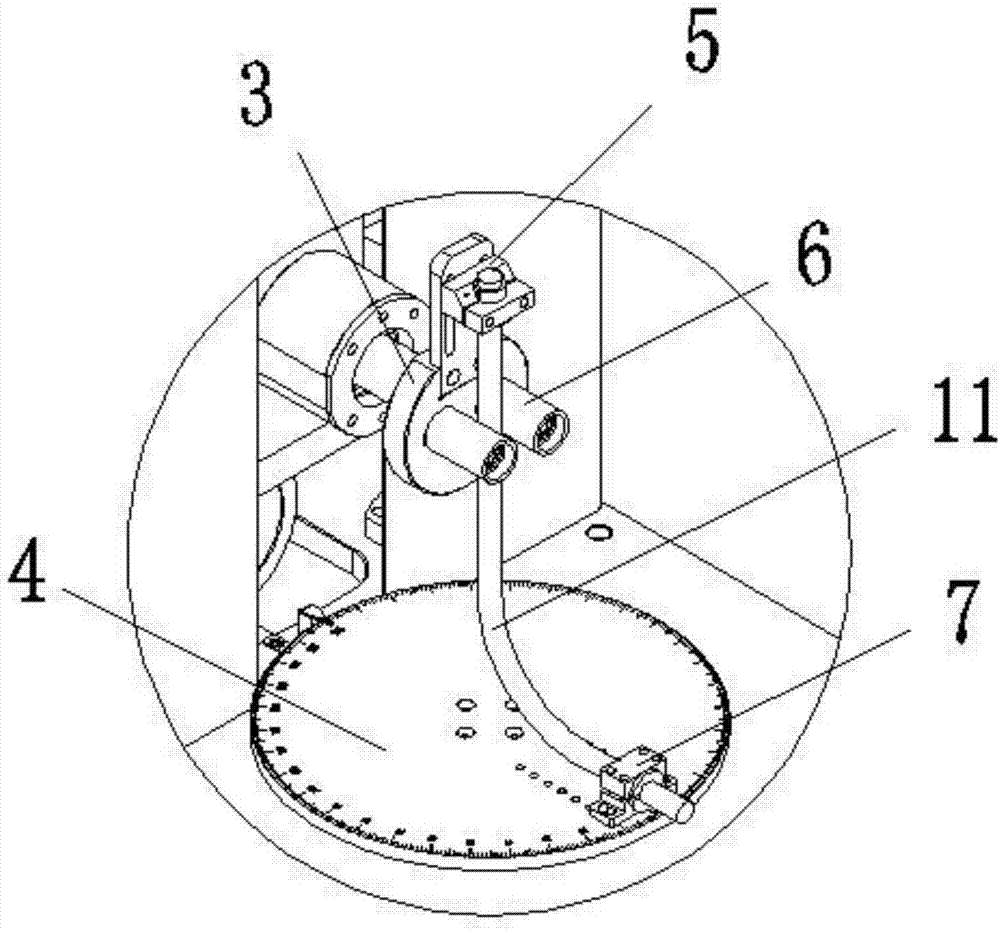

[0015] as attached Figure 1-2 As shown, a composite electric wire torsional bending testing machine according to the present invention includes a frame 1 on which a control system, a bending transmission assembly 2, a torsion transmission assembly and a cooling fan 8 are arranged; the bending transmission assembly 2. It is set on the frame 1 through the lifting structure, and the height of the bending transmission assembly 2 is controlled by the control system. The bending transmission assembly 2 is connected with a rotating part 3, and the twisting transmission assembly is provided with a turntable 4. The rotation axis of the rotating part 3 is in line with the turntable. The axis of rotation of 4 is vertical; the rotating part 3 is provided with an upper fixture 5 and two curvature rollers 6, and the upper end of the tested electric wire 11 passes between the two curvature rollers 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com