Flexible light bar connector structure

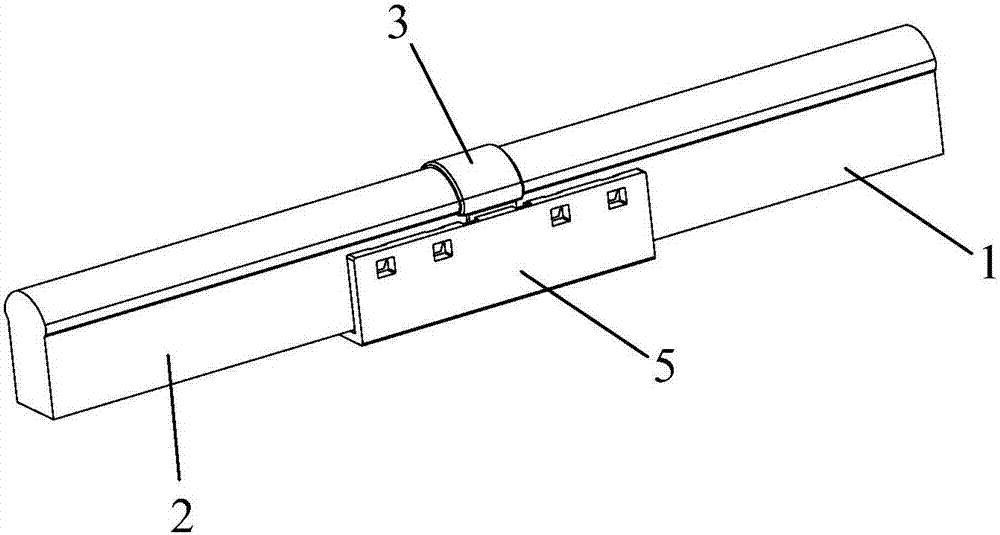

A technology of flexible light bar and joint structure, applied in the field of decorative lights, can solve the problems of complex structure and complicated installation method, and achieve the effect of eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

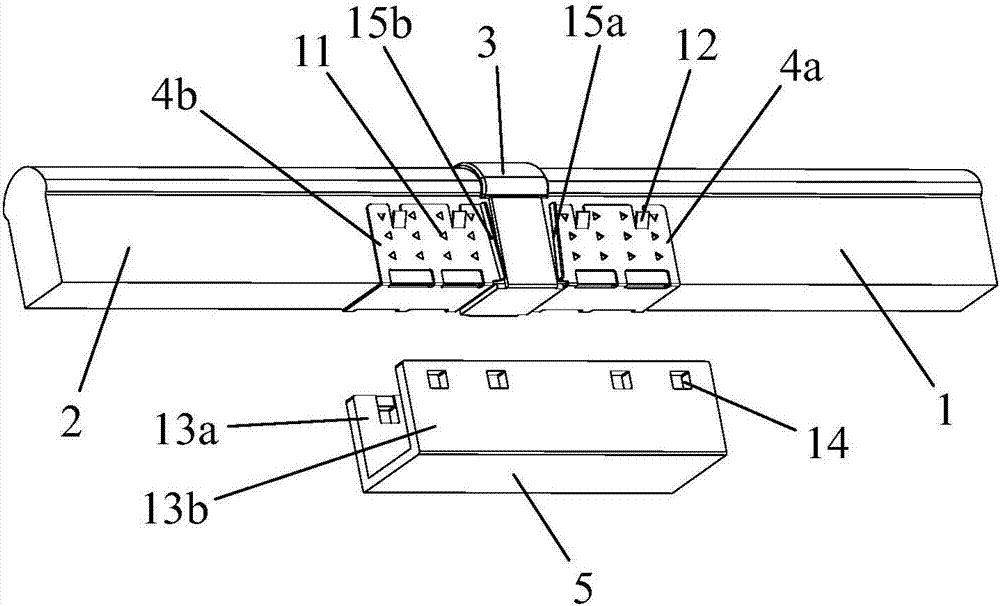

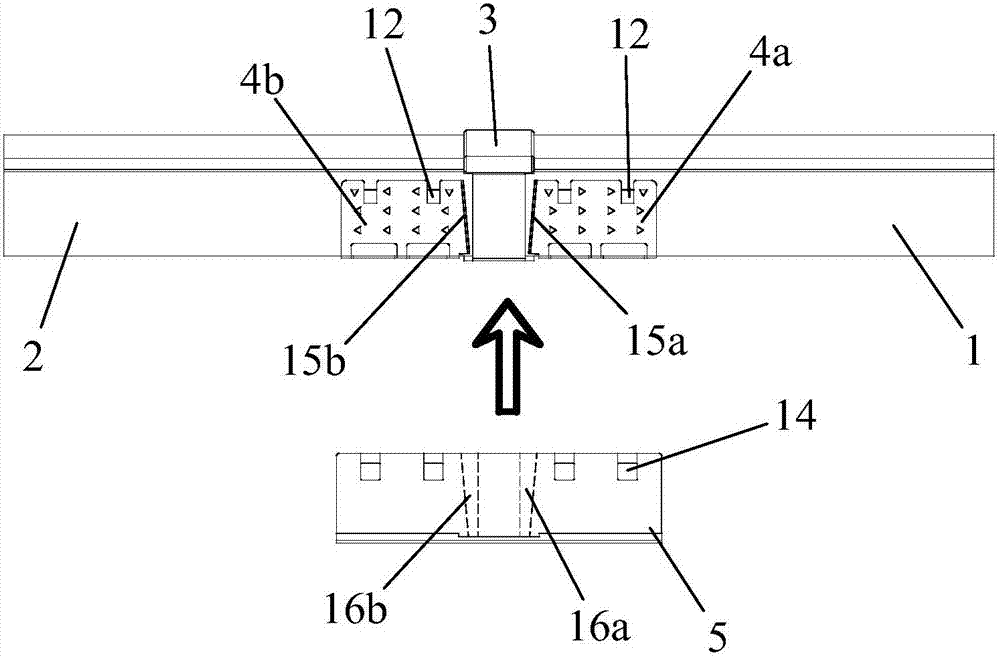

[0044] refer to Figure 9 to Figure 12 The third preferred embodiment of the present invention is a front joint structure of a flexible light bar, including:

[0045] A power connector 17, the two sides of the power connector 17 are made of hard material and are provided with a second buckle part 18;

[0046] The concave spine 4a, the two sides 10a, 10b of the concave spine 4a are closely attached to the two sides of the first light bar 1, and the side of the spine 4a facing the first light bar 1 is provided with a spike 11, It is used to press against or pierce the side of the first light bar 1; the side of the spine 4a facing away from the first light bar 1 is provided with a first buckle part 12;

[0047] The hard set 5, the hard set 5 is provided with two clamping walls 13a, 13b, clamps the power connector 17 and the first light bar 1 and presses the spine piece 4a tightly on the side of the first light bar 1 The clamping walls 13a, 13b are provided with a first fastenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com