Testing method of single-pile multi-directional horizontal bearing force under combined loading effect

A technology of horizontal bearing capacity and test method, which is applied in the test of foundation structure, construction, infrastructure engineering and other directions, can solve the problem of inability to effectively test the multi-directional horizontal bearing capacity of a single pile, and achieves the solution of field test problems, low cost, long-term effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

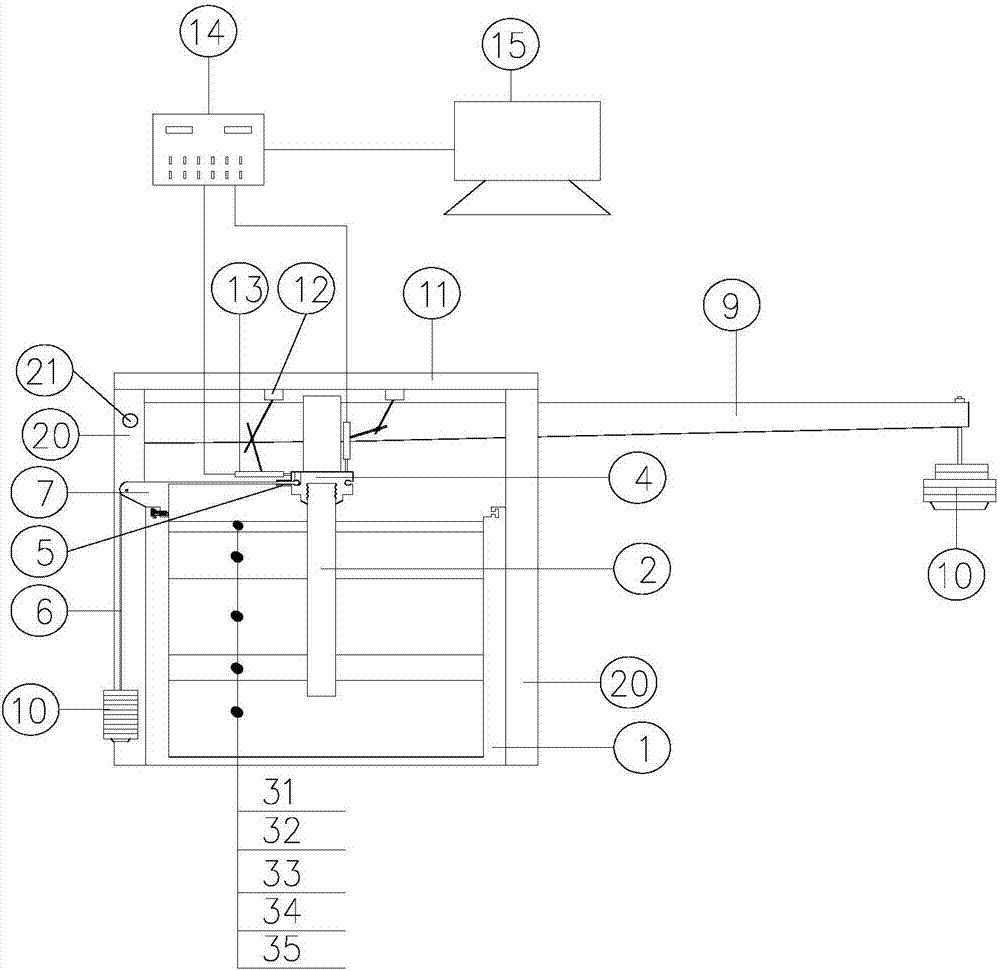

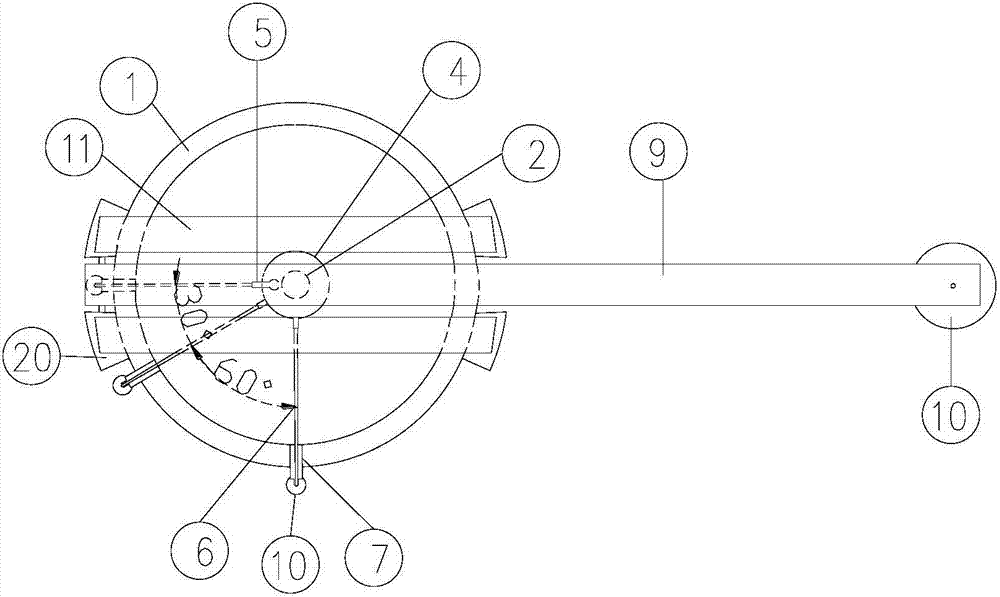

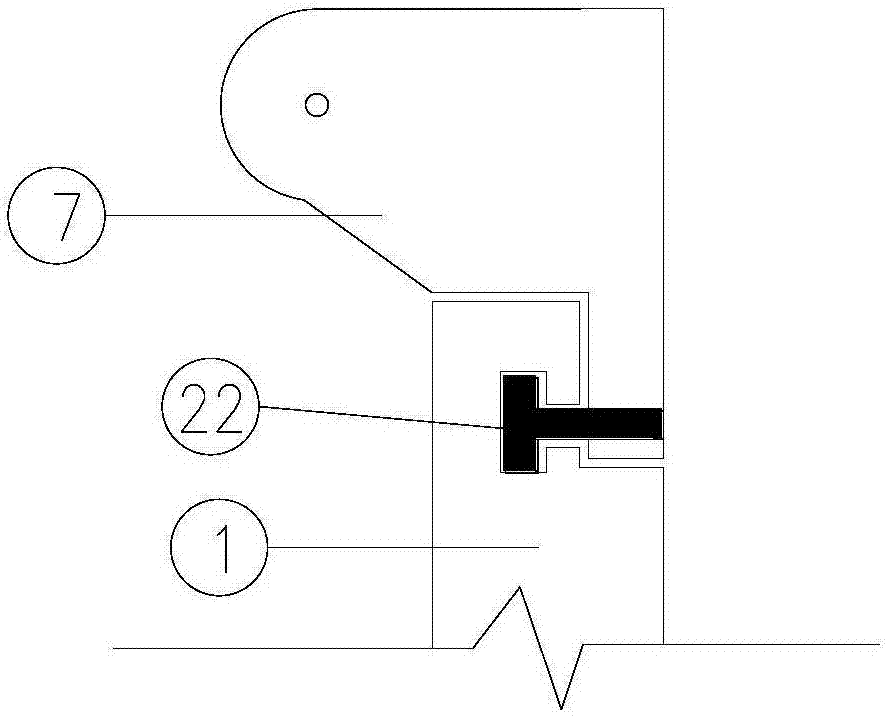

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] refer to Figure 1 to Figure 6 , a method for testing the multi-directional horizontal bearing capacity of single piles under the action of composite loads, the device for realizing the test method includes a model box, a vertical loading system, a horizontal loading system and a data acquisition system, and laying simulation in the model box The soil in the box of the site, the test single pile is embedded in the soil in the box, the vertical loading system includes a column, a beam, a lever, a vertical loader and a vertical loading weight, and one end of the lever is hinged on two On the rotating shaft between the upright columns, a vertical loader is installed in the middle of the lever, and the vertical loader is located at the top of the test single pile, and the other end of the lever is connected with a vertical load weight; the horizontal The loading sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com