Pipe welding outward galvanization device

A technology of welded pipe and zinc pot, which is applied in hot-dip galvanizing process, coating, metal material coating process, etc. It can solve the problems of welded pipe shutdown, low efficiency of welded pipe galvanizing, welded pipe superposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is realized through the following technical solutions:

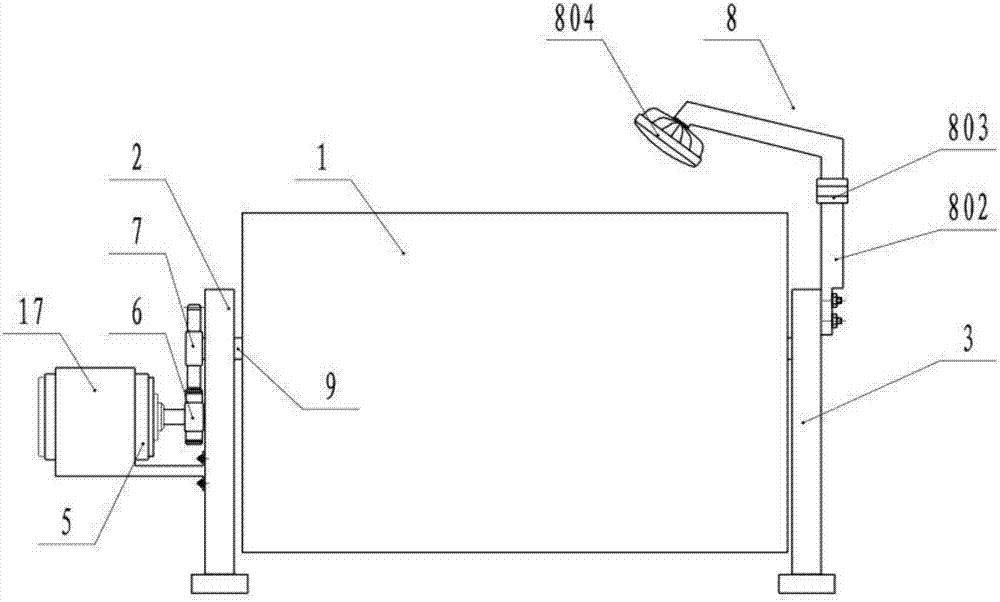

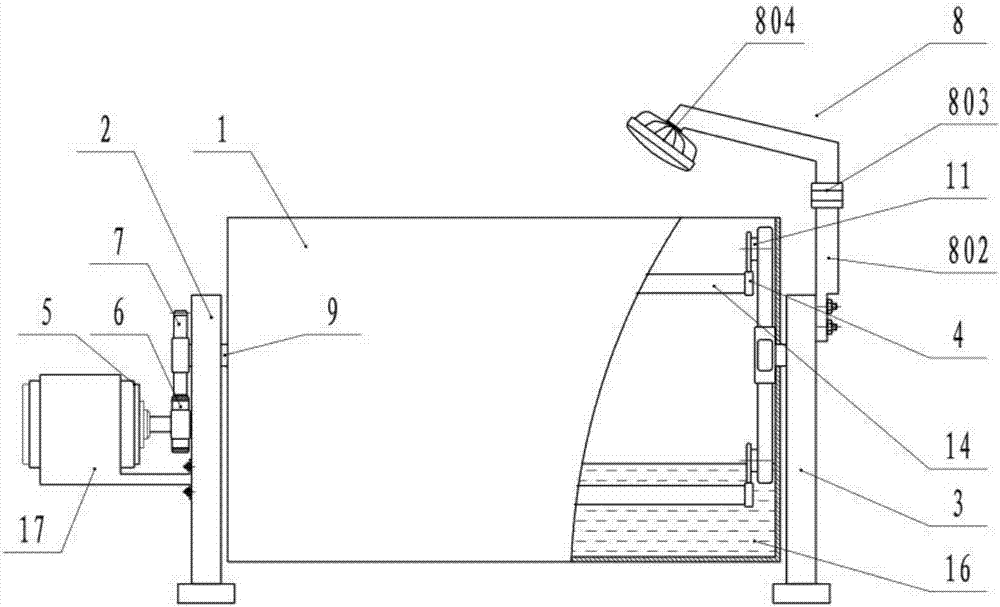

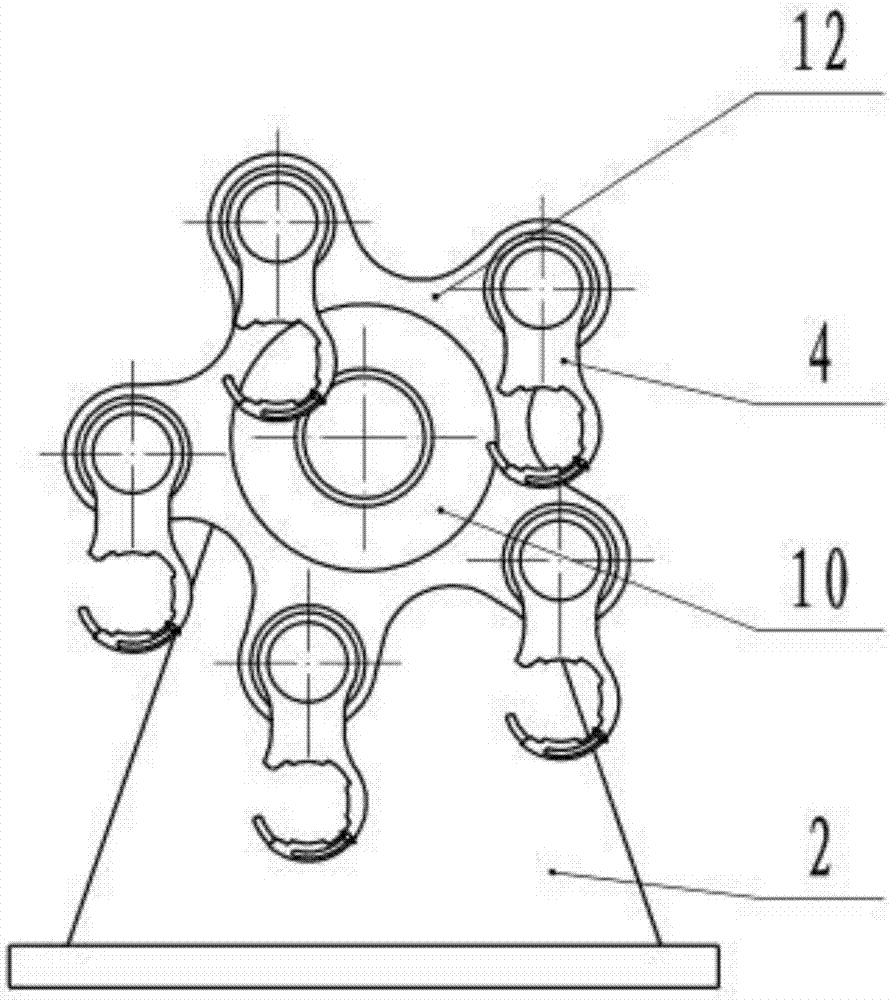

[0020] An external galvanizing device for welded pipes, comprising a zinc pot 1, a first fixing seat 2, a second fixing seat 3, a pipe hanging device 4, a motor 5, a driving gear 6, a driven gear 7, a zinc blowing device 8, and a connecting shaft 9. The tooth plate 10, the rotating shaft 11 and the gear teeth 12 are characterized in that: the first fixing seat 2 and the second fixing seat 3 are respectively arranged on both sides of the zinc pot 1 to support and fix the zinc pot 1, and the The zinc pot 1 is in the shape of a cuboid; the motor 5 is installed and fixed on the outside of the first fixed seat 1, the driving gear 6 is arranged on the power output end of the motor 5, the driving gear 6 is meshed with the driven gear 7, and the driving gear 6 is engaged with the driven gear 7. The driven gear 7 is arranged on the outside of the first fixed seat 2 through the connecting shaft 9, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com