A feeding device for an extrusion extruder

A technology of extrusion extruder and feeding device, which is applied in the direction of feed, food science, application, etc., can solve the problems of uneven feeding, device bridging and blocking, etc., achieve the anti-blocking function, prevent material accumulation, and solve the problem of feeding uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

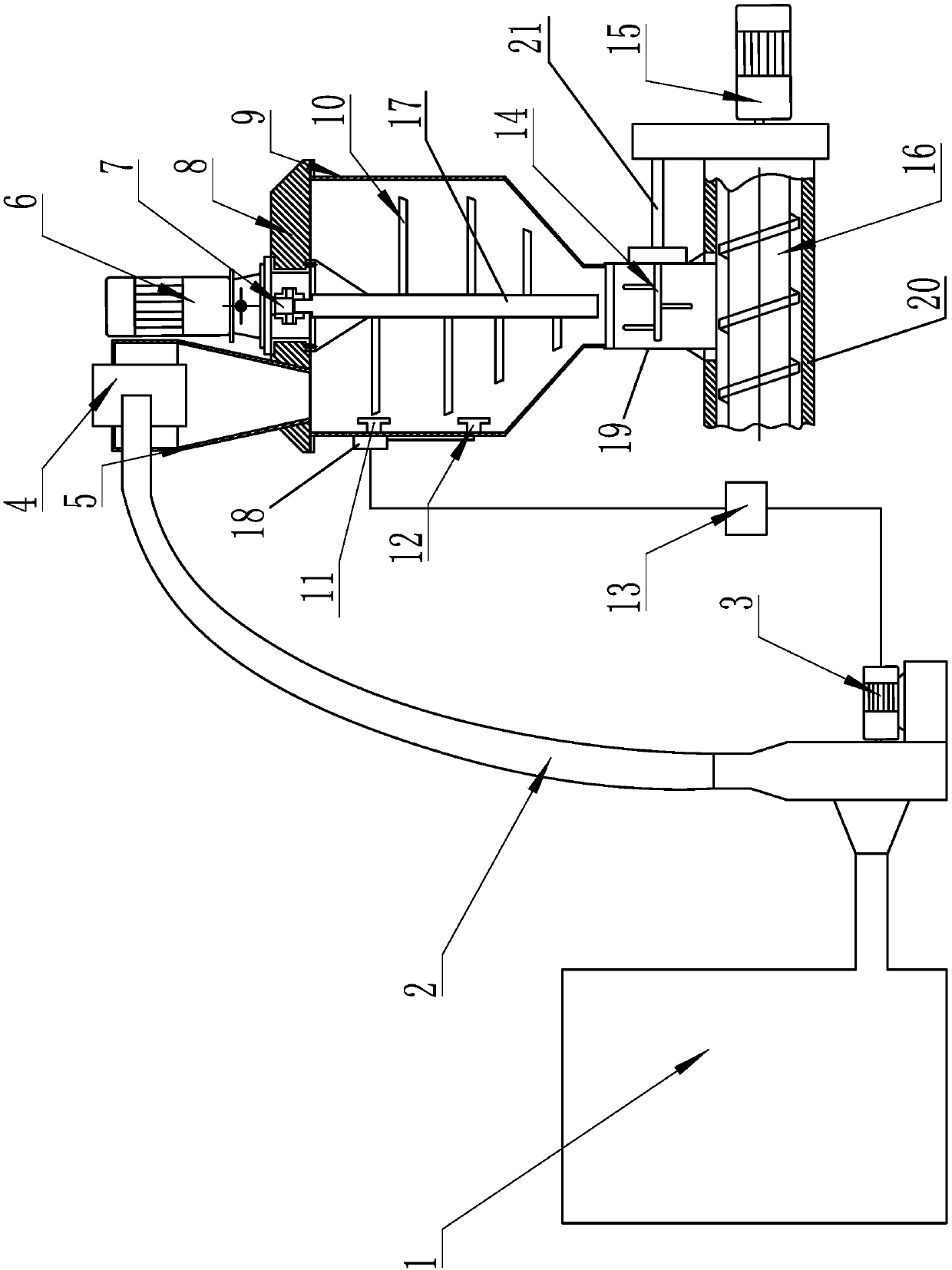

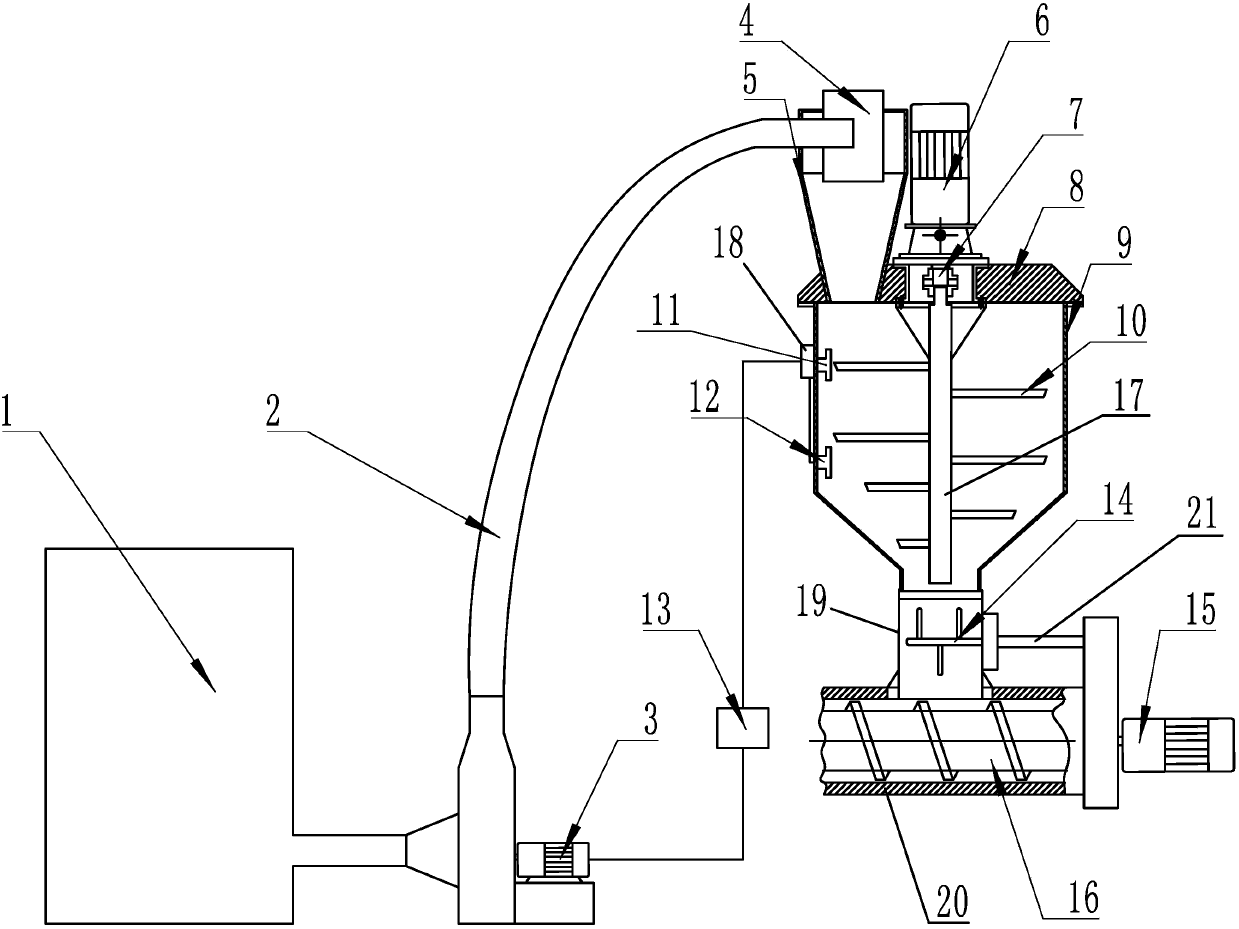

[0019] The present invention will be further explained below in conjunction with the drawings:

[0020] Such as figure 1 As shown, a feeding device for an extrusion extruder, the feeding device is composed of a feeding device, a stirring device, an anti-blocking device and a feeding device;

[0021] Such as figure 1 As shown, an extruder feeding device is composed of a material box 1, a feeding motor 3, a feeding pipe 2, a material splitter 4, and a hopper 5; the material box 1 is fixed on the ground, and the material box 1 It is connected to the material diverter 4 through the feeding pipe 2, the feeding motor 3 is arranged at the outlet of the material box 1, and the hopper 5 is connected and arranged below the material diverter 4;

[0022] Such as figure 1 As shown, a feeding device for an extruder is shown. The stirring device is composed of a stirring motor 6, a barrel 9, a stirring shaft 17 and a stirring blade 10. The top of the barrel 9 is provided with a fixed cover 8 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com