Centrifugal cone-disk high-speed seeding unit

A cone-disc type, high-speed technology, applied in the direction of seeder parts, etc., can solve the problems of high power consumption, increased missed seeding rate, and difficult seed filling process, etc., to achieve high operating efficiency, low missed seeding rate, and novel structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

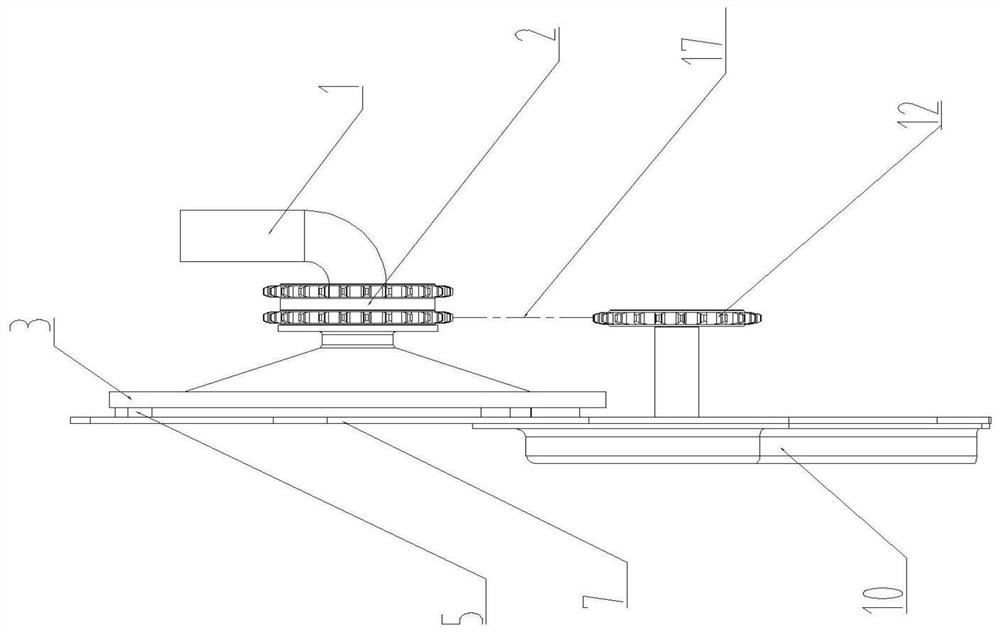

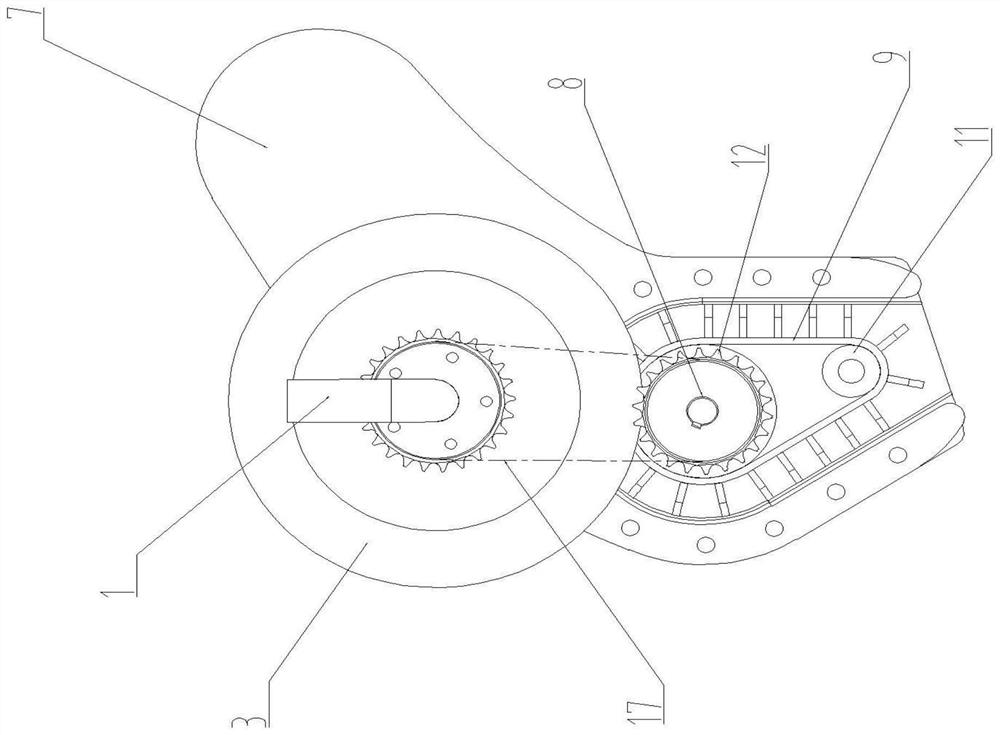

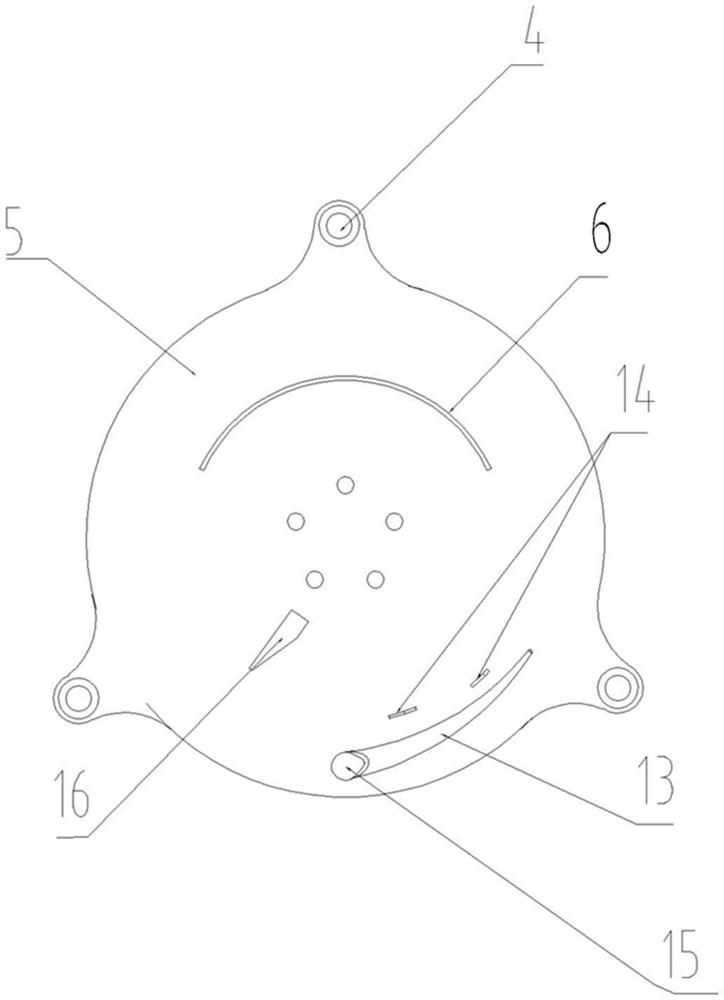

[0014] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A centrifugal cone-disc type high-speed seeding unit, a seeding disc 5 is fixed on one side of a U-shaped notch-type fixed plate 7, and bearings 4 are evenly distributed on the edge of the seeding disc 5 along the circumferential direction. The outer end surface of the seeding disk 5 is respectively fixed with an annular seed protection sheet 6, a blockage removal sheet 14 and a seed block 16, and a slope-shaped arc is arranged on the outer end surface of the seeding disk 5 at the lower side of the blockage removal sheet 14. Shaped seed introduction groove 13, described slope-shaped arc-shaped seed introduction groove 13 communicates with the unloading through-hole 15 on the seed-discharging disc 5; On the fixed seed-filling pipe 1, it is axially and radially positioned and circumferentially rotatable and fits and installs The centrifugal cone 3, the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com