Method for accurately arranging positions and postures of rice seeds

A rice seed and posture technology, which is applied in the field of sowing machinery, can solve the problems of inability to achieve directional sowing, low seeding precision, troublesome operation, etc., and achieve the effects of simple structure, improved seed filling rate, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

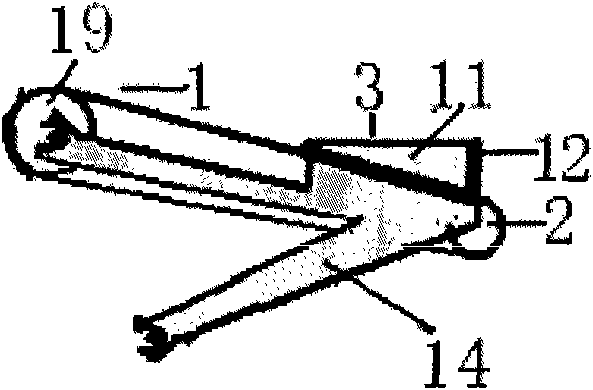

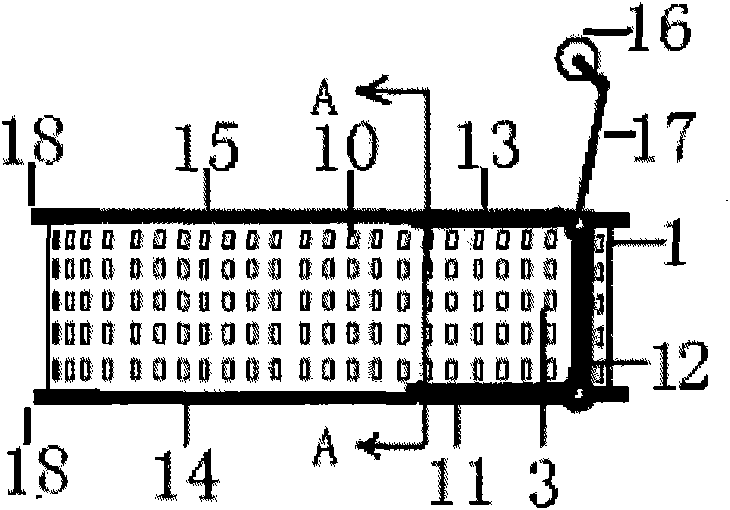

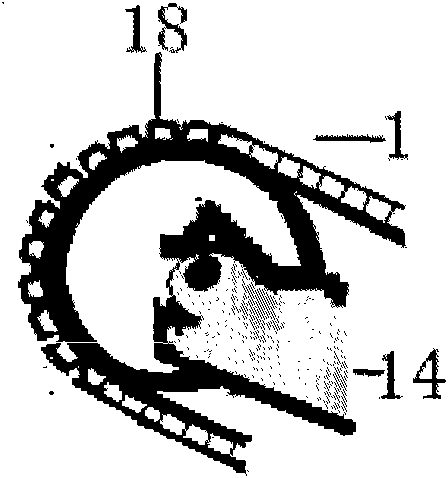

[0023] Method 1 is a device for accurately arranging the position and posture of rice seeds, which consists of a seed supply box, a frame, a seed belt (1), a vibrating wheel (2), a seeding chamber (3), a driving support wheel (19) and a vibrating device constitute.

[0024] The seed-discharging belt (1) is an elastic flexible ring-shaped belt with recesses (10) on the surface, and an upwardly protruding seed protection side weir on the edge of the outer surface. on the wheel (19).

[0025] The axle of driving supporting wheel (19) is installed on the frame, and supporting driving wheel (19) can only rotate relative to the frame, and can not vibrate.

[0026] The two ends of the drive support wheel (19), the vibrating wheel (2) have a seed-discharging belt constraint ring protruding outward from the periphery.

[0027] The axle of vibrating wheel (2) and the axle of driving supporting wheel (19) are installed on the vibrating device that can vibrate along its axial direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com