Coil arrangement and transformer with low inter-winding capacitance

A coil arrangement and transformer technology, applied in discontinuous variable inductors/transformers, transformer/inductor components, coils, etc., can solve problems such as increased power loss, damage to the performance of coil layout structures, and increased winding resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

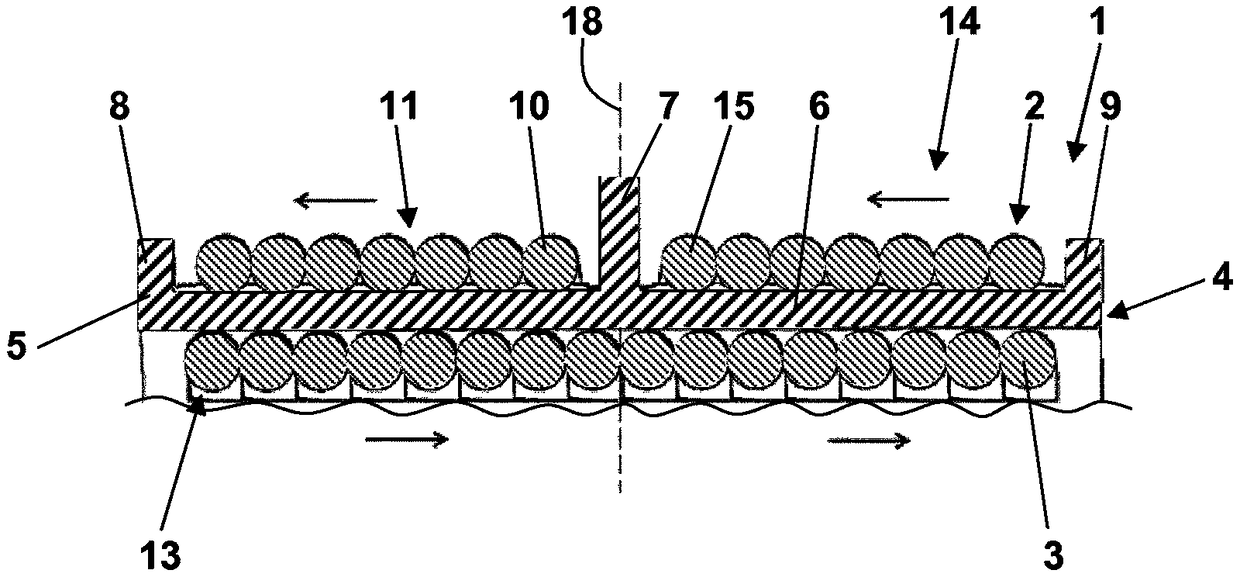

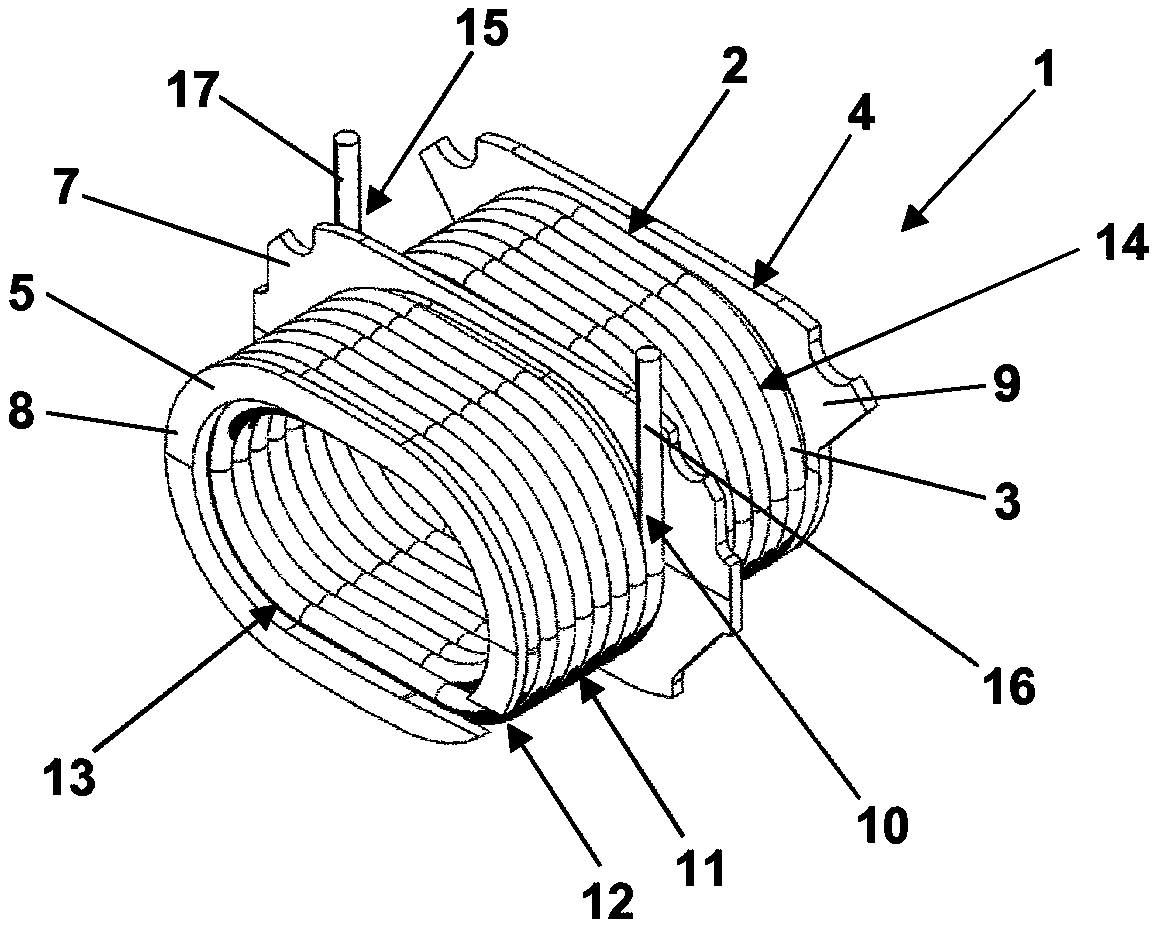

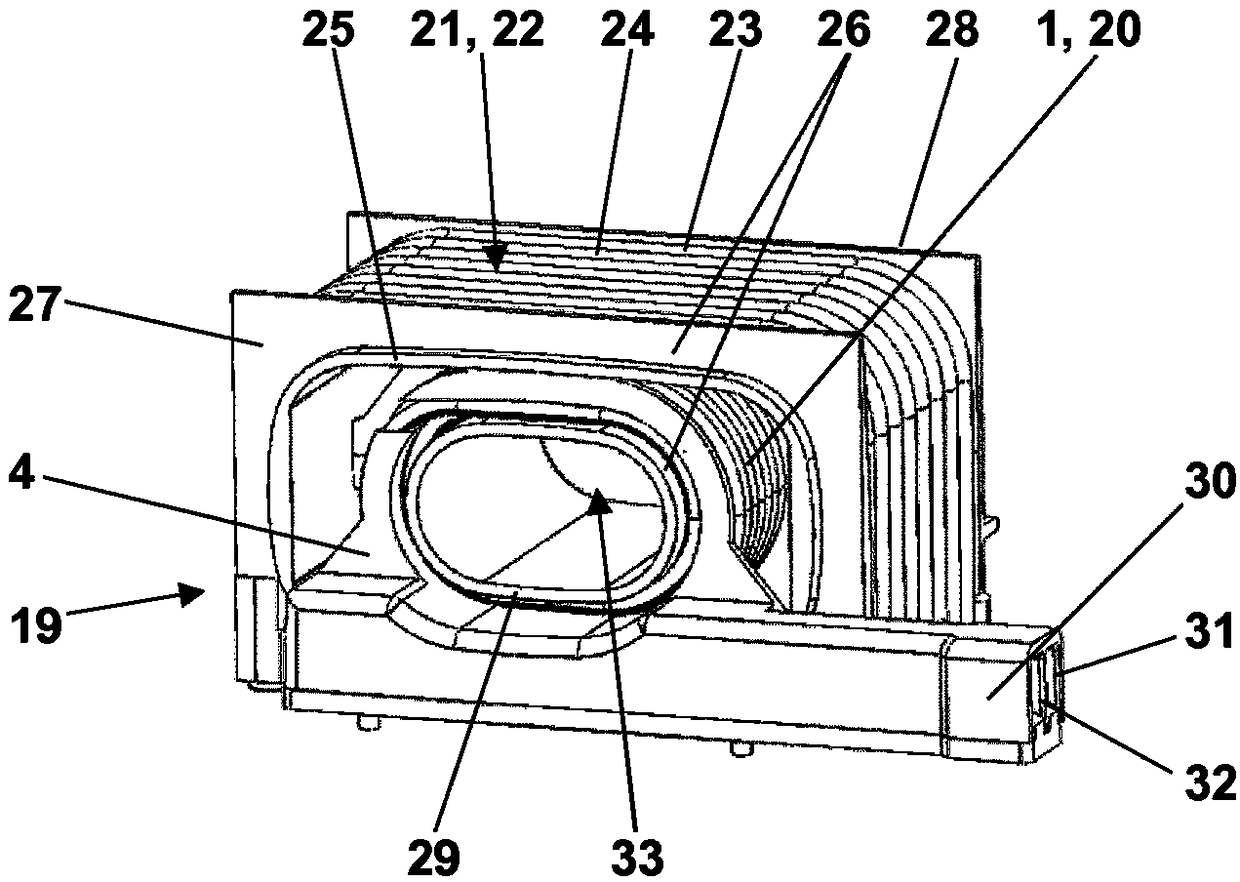

[0050] in accordance with figure 1 with 2 In the coil arrangement of , a single continuous conductor segment 2 formed of a solid wire 3 is wound within and around a bobbin 4 made of electrically insulating material 5 . The spool 4 comprises a tubular wall 6, a central flange 7, made of said material 5 and extending radially from the outside of the wall 6, and two end flanges 8 and 9, said two end flanges 8 and 9. Flanges 8 and 9 are also made of said material 5 and extend radially from the outside of wall 6 . Starting from the start 10 , the successive conductor segments 2 first form a first set of conductor windings 11 on the outside of the wall 6 . The continuous conductor segment 2 then passes through the opening 12 in the end flange 8 . The continuous conductor segments 2 then form a second set of conductor windings 13 at the inner side of the wall 6 . Next, the continuous conductor section 2 passes through the opening in the end flange 9 before it finally forms the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com