Method of diagnosing fault of thickener during hydrometallurgy process

A technology of hydrometallurgy and fault diagnosis, applied in program control, instrumentation, electrical testing/monitoring, etc., can solve problems such as large time lag, complex process and frequent changes in dense washing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

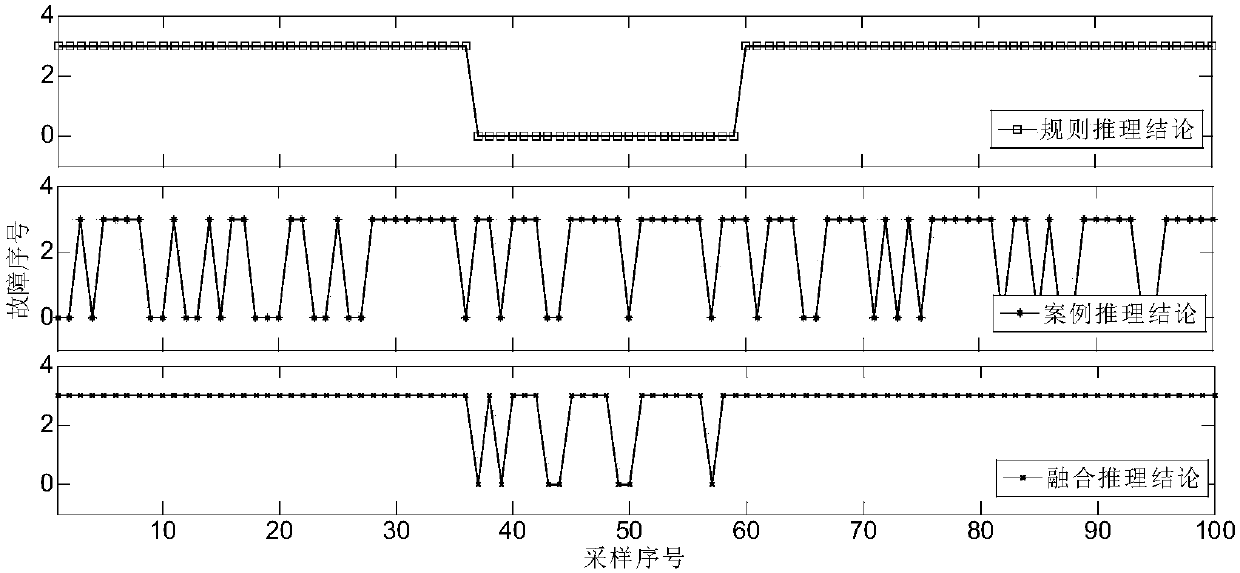

Image

Examples

Embodiment Construction

[0068] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0069] The device involved in the invention includes an intelligent fault diagnosis system for a hydrometallurgical thickener, a host computer, a PLC, an on-site sensing and transmitting part and a human-computer interaction device. Among them, the on-site sensing and transmission part includes detection instruments such as concentration, pressure and flow.

[0070] The detection instrument is installed on-site in the hydrometallurgical process. The detection instrument sends the collected signal to the PLC through the Profibus-DP bus. The PLC transmits the collected signal to the host computer through Ethernet at regular intervals. Machine intelligent fault diagnosis system, to identify process conditions and diagnose faults.

[0071] The functions of each pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com