Method of Analysis of Main Error Factors of Belt Scale Based on Multiple Linear Regression Model

A technology of multiple linear regression and factor analysis, which is applied in the fields of control, manufacturing equipment testing, diagnosis and maintenance, can solve problems such as the influence of accuracy, and achieve the effects of compensation accuracy, fast calculation, and accurate calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

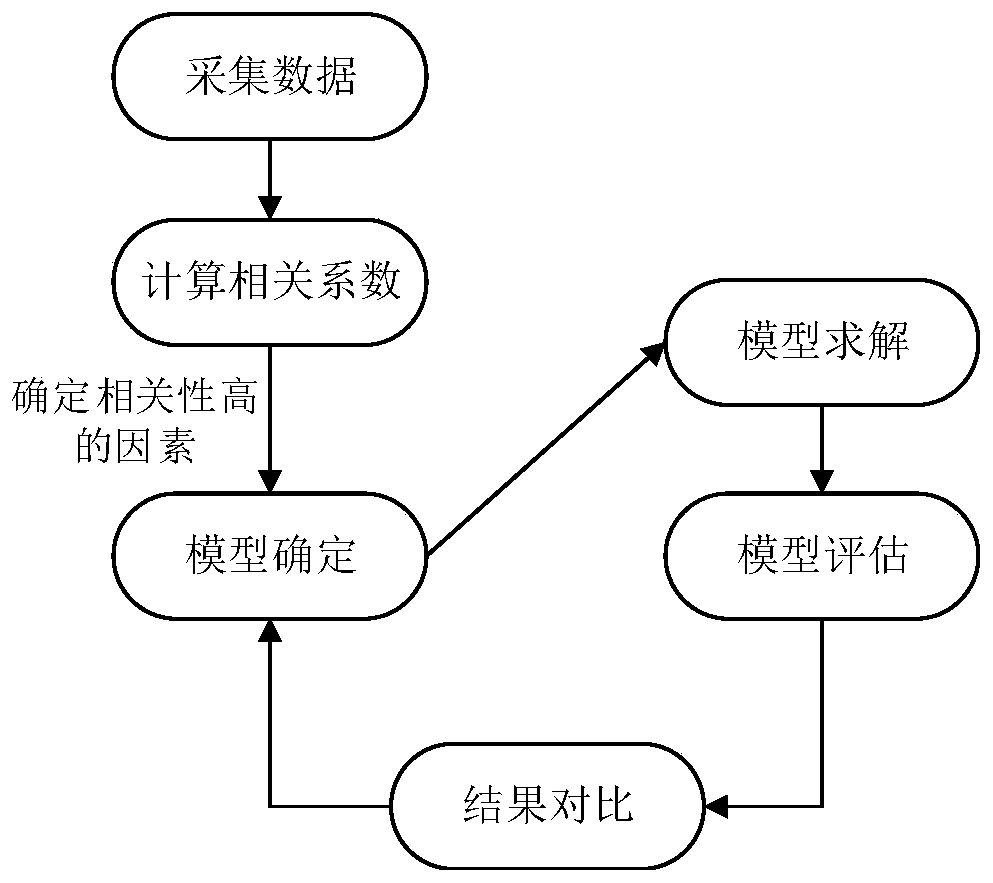

[0014] The technical route of the present invention is further described in conjunction with the accompanying drawings, and the example applied here is applicable to the analysis of the relationship between the error influencing factors of the electronic belt scale.

[0015] refer to figure 1 A method for analyzing the main error factors of a belt scale based on a multiple linear regression model of the present invention comprises the following steps:

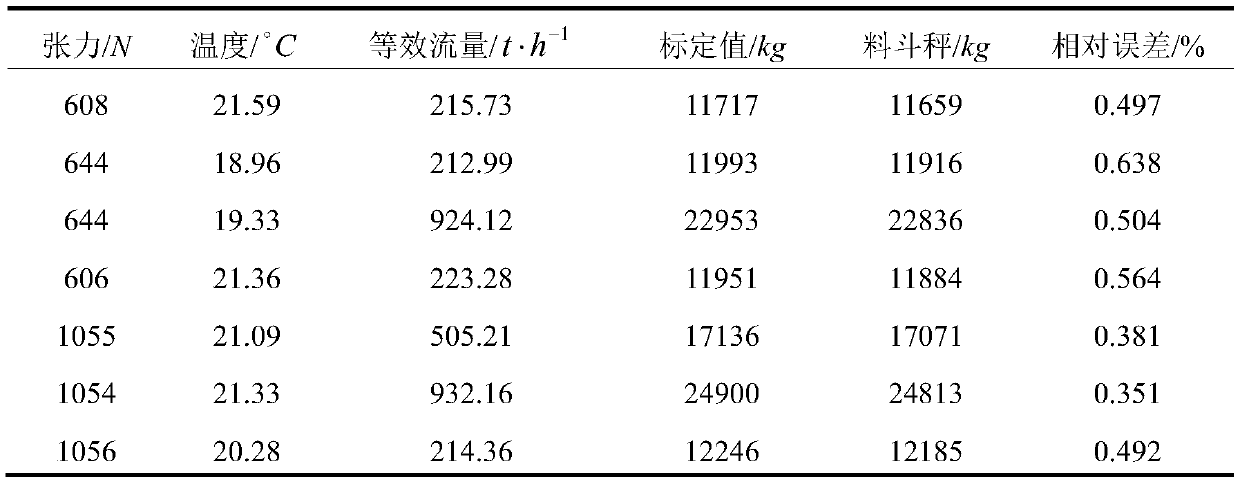

[0016] Step 1. Build a belt scale experimental platform, change the main error factors such as tension, temperature, and equivalent flow according to the actual situation, record the tension, temperature, equivalent flow, calibration value and hopper scale of each test point, and calculate the calibration value and The relative error of the hopper scale, that is, the precision value of the belt scale, the experimental data are shown in Table 1:

[0017] Table 1 Experimental data

[0018]

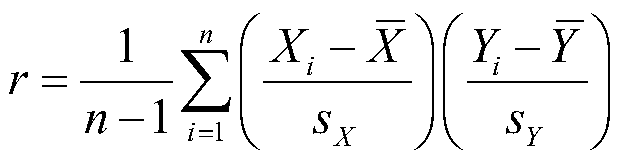

[0019] Step 2, calculating the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com