Immersive man-machine environment interactive positioning measurement method

A technology for positioning measurement and environment, applied in measurement devices, radio wave measurement systems, satellite radio beacon positioning systems, etc., can solve problems such as reducing work efficiency, restricting work efficiency and product quality improvement, poor flexibility, etc. The effect of efficiency and quality, good human-computer interaction experience, and good portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

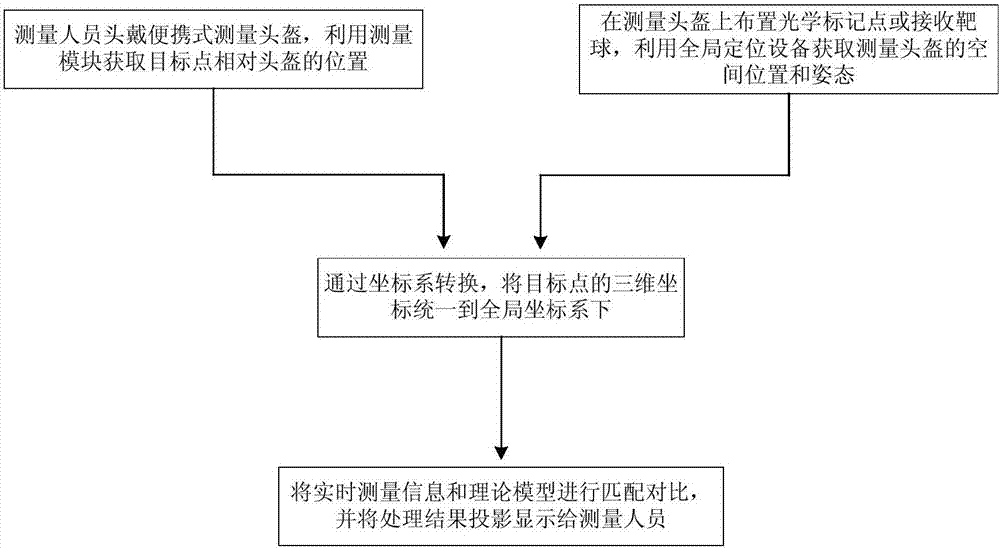

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

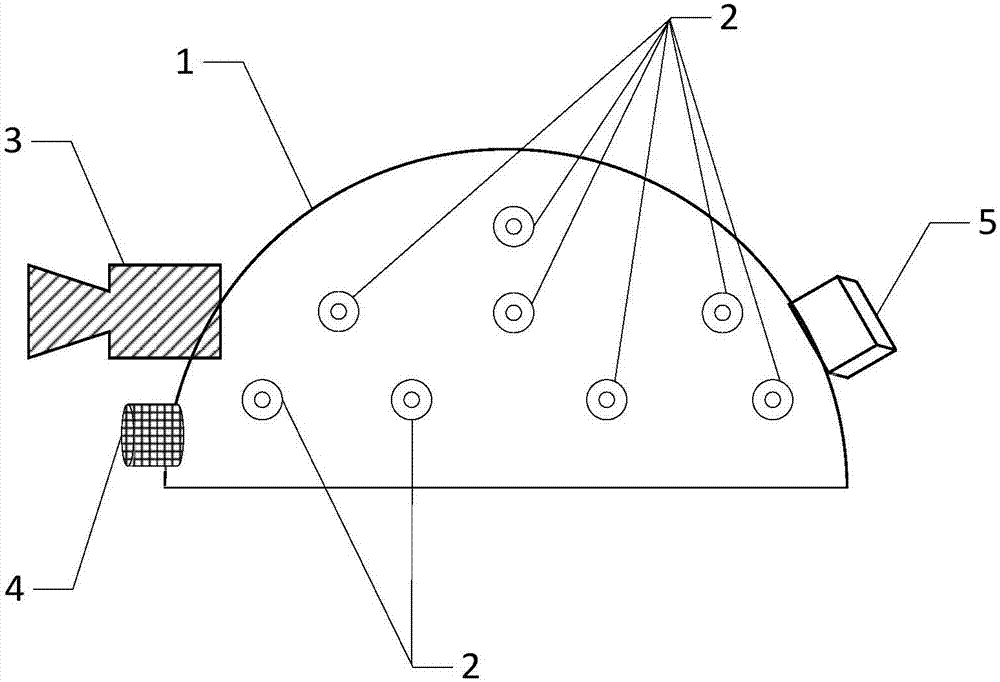

[0019] The integrated human-computer environment interactive positioning measurement method proposed by the present invention first needs to build a portable measurement helmet that can be worn by the measurement personnel. Its basic structure is as follows: figure 1 shown. In this embodiment, the measurement helmet mainly includes a helmet shell 1, a measurement module 3, a projection module 4, and a communication and power supply module 5,

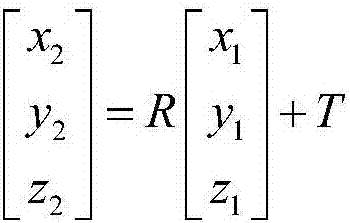

[0020] Among them, the measurement module is used to obtain the spatial coordinates of the target point, and the coordinate system conversion relationship between the measurement module 3 and the measurement helmet needs to be calibrated in advance before use; the projection module 4 projects the information to the front of the measurement personnel, so that the measurement personnel can obtain an intuitive Graphical display; the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com