Multifunctional supporting base

A support base, multi-functional technology, applied in the direction of supporting machines, machines/brackets, mechanical equipment, etc., can solve problems such as unreliable fixation, increased space occupied by equipment, and small contact surface of universal wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

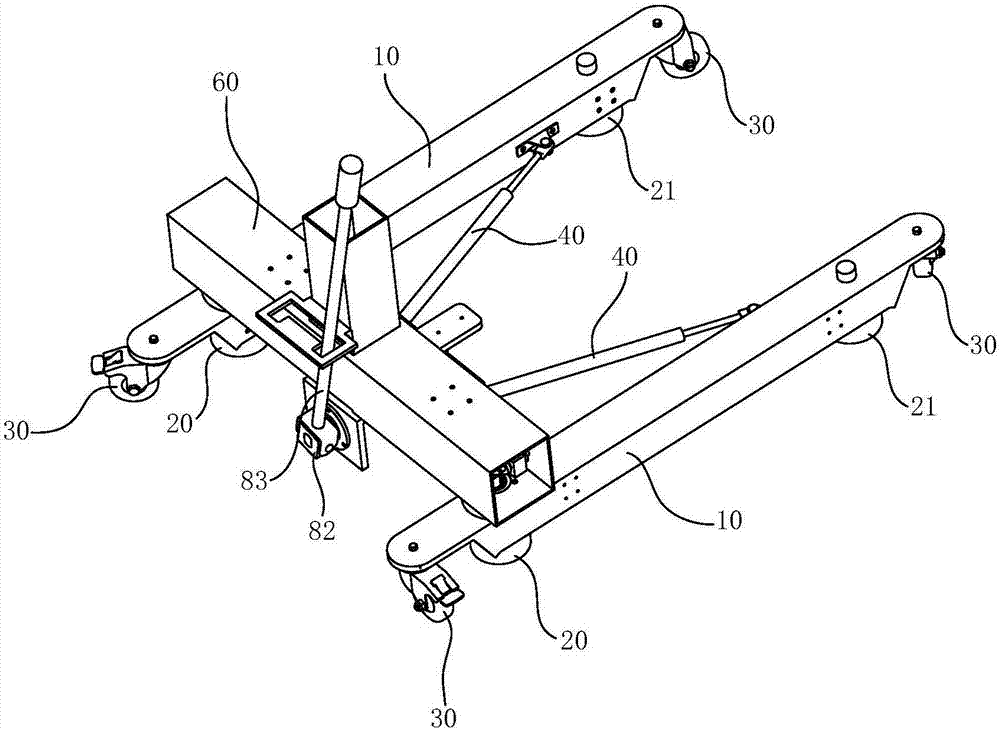

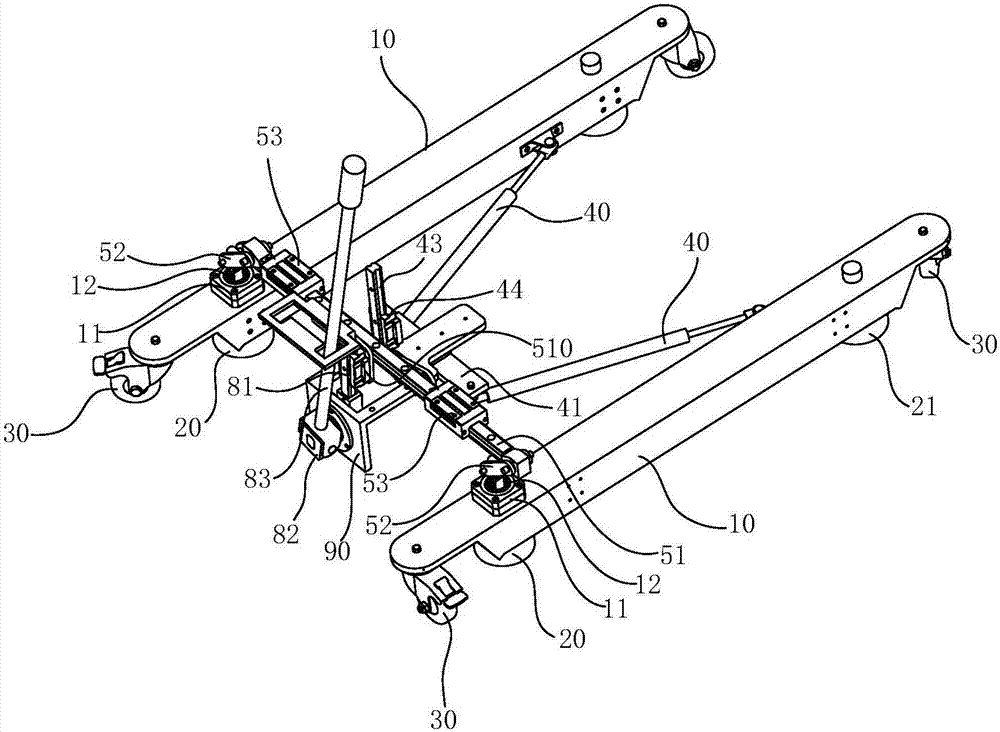

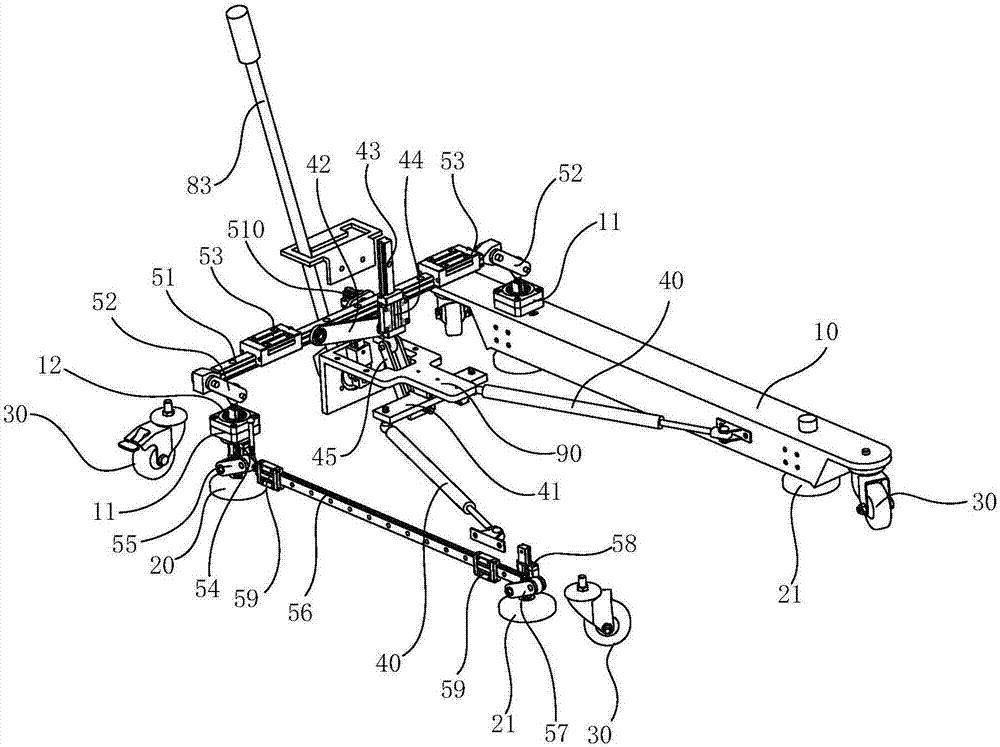

[0024] combine Figure 1 to Figure 6 , the present invention is further described:

[0025] A multifunctional support base, the base is composed of at least two support rods 10, the rod length direction of the support rods 10 is horizontal and in the same horizontal plane, the support rods are provided with proximal support feet 20 and Far-end supporting foot 21, described base is provided with driving mechanism, and driving mechanism drives near-end supporting foot 20 and far-end supporting foot 21 to move up and down and the lower end of near-end supporting foot 20 and far-end supporting foot 21 is separated from the ground or against By the way, the base is also provided with a linkage mechanism, and the linkage mechanism drives the support rods 10 to rotate around the proximal support legs 20 respectively. The vertical movement of the proximal support leg 20 and the distal support leg 21 cooperates with the rotation of the support rod 10 around the proximal support leg 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com