Subway tunnel pressure-relief-hole air pressure control method and system

A technology of wind pressure control and pressure relief holes, which is applied in mine/tunnel ventilation, earthwork drilling, mining equipment, etc. It can solve the problems of reducing train speed, increasing construction difficulty, increasing investment, etc., and achieves comfortable urban rail transit , convenient operation and maintenance, and simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

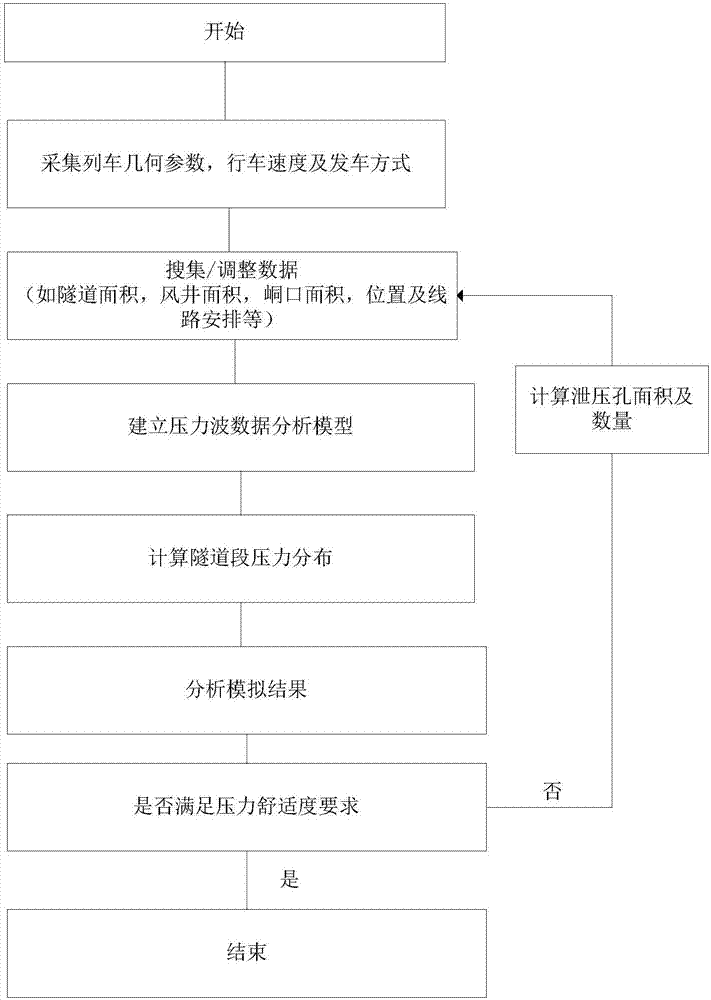

[0034] The invention provides a method for controlling wind pressure at a pressure relief hole of a subway tunnel, comprising the following steps:

[0035] S1, the system collects relevant parameters of the train, and the parameters include driving speed and departure mode;

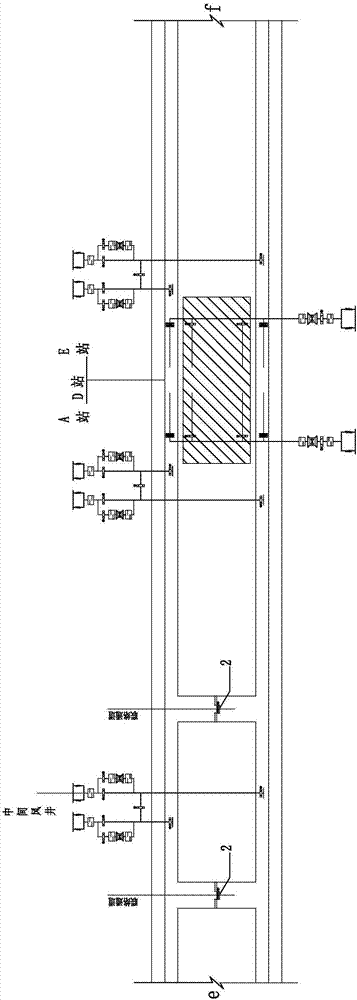

[0036] S2. The system collects and adjusts the data of the working environment, the data includes tunnel area, wind shaft area, cave opening area and line location setting;

[0037] S3. The system establishes a pressure wave data analysis model, and calculates the pressure change threshold distribution of the tunnel section;

[0038] S4. The system judges whether the simulation result meets the pressure comfort requirement, and if so, ends the simulation; if not, calculates the area, quantity and location of the pressure relief holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com