Bridge erecting machine for precast segmental beam span by span construction and construction method thereof

A technology for segment beams and bridge erection machines, which is applied in the directions of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as increased labor costs, complex construction conditions, and reduced construction work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

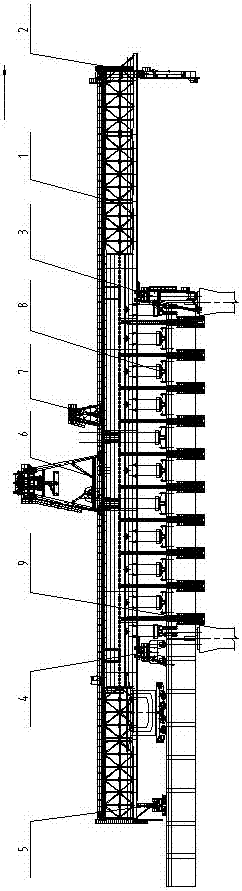

[0118] The direction of the arrow in the accompanying drawings indicates the erection direction of the bridge erecting machine construction method used for the span-by-span construction of the prefabricated segmental beams.

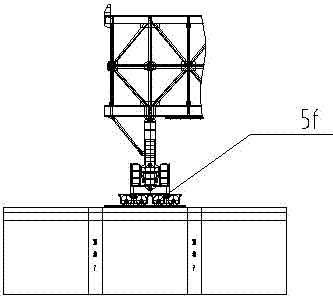

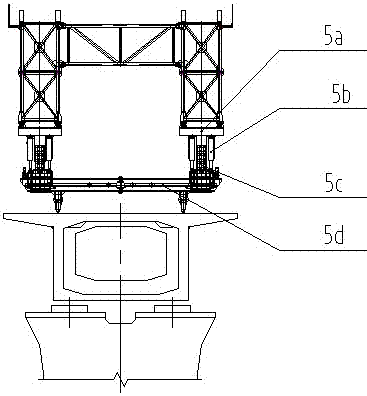

[0119] Such as figure 1 As shown, the bridge erecting machine used for the span-by-span construction of prefabricated segmental beams includes the main frame 1, outrigger system, hanging system, wet joint formwork system and crown block system. The outrigger system includes longitudinal The No. 1 outrigger 2, the No. 2 outrigger 3, the No. 3 outrigger 4 and the No. 4 outrigger 5 are arranged in sequence from front to back, wherein the No. 1 outrigger 2 and the No. 4 outrigger 5 are respectively located on the two sides of the main frame 1 The end is used as an auxiliary support leg, the second leg 3 and the third leg 4 are heavy-duty support legs, the hanging system is connected to the bottom of the main frame 1, and the wet joint formwork system is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com