Processing process for rice

A processing technology, rice technology, applied in lighting and heating equipment, filter screens, grills, etc., can solve the problems of damaging the nutritional value of rice, affecting sales and consumption, and easily producing rice worms, etc., to achieve good dehumidification effect and increase Drying and cooling time, the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A rice processing technology, comprising the following steps:

[0030] S1. Impurity removal: Put the harvested rice into the cylindrical sieve for screening to remove rice rhizomes, weeds, stones and other sundries;

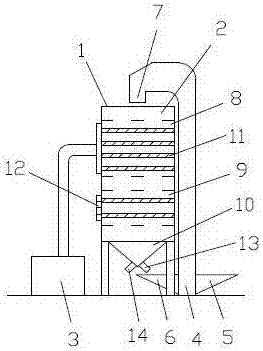

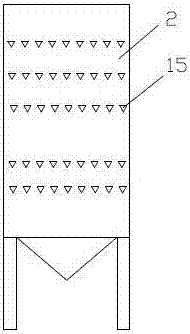

[0031] S2. Drying: the screened rice is dried circularly through a special grain dryer 1, the grain dryer 1 includes a drying cylinder 2 and is arranged on the outside of the drying cylinder 2 and connected to the inside of the drying cylinder 2. The connected hot blast stove 3, the drying cylinder 2 is provided with a lifting device 4, and the lifting device 4 includes a feed port 5 and a material receiving port 6 arranged at the bottom of the lifting device 4, and the top of the lifting device 4 is provided with There is feeding port 7. The interior of the drying cylinder 2 includes a drying section 8, a cold air section 9, and a displacement section 10 from top to bottom. The hot blast stove 3 is connected to the drying section 8, and the temperature g...

Embodiment 2

[0042] A rice processing technology, comprising the following steps:

[0043] S1. Impurity removal: Put the harvested rice into the cylindrical sieve for screening to remove rice rhizomes, weeds, stones and other sundries;

[0044]S2. Drying: the screened rice is dried circularly through a special grain dryer 1, the grain dryer 1 includes a drying cylinder 2 and is arranged on the outside of the drying cylinder 2 and connected to the inside of the drying cylinder 2. The connected hot blast stove 3, the drying cylinder 2 is provided with a lifting device 4, and the lifting device 4 includes a feed port 5 and a material receiving port 6 arranged at the bottom of the lifting device 4, and the top of the lifting device 4 is provided with There is feeding port 7. The interior of the drying cylinder 2 includes a drying section 8, a cold air section 9, and a displacement section 10 from top to bottom. The hot blast stove 3 is connected to the drying section 8, and the temperature ge...

Embodiment 3

[0055] A rice processing technology, comprising the following steps:

[0056] S1. Impurity removal: Put the harvested rice into the cylindrical sieve for screening to remove rice rhizomes, weeds, stones and other sundries;

[0057] S2. Drying: the screened rice is dried circularly through a special grain dryer 1, the grain dryer 1 includes a drying cylinder 2 and is arranged on the outside of the drying cylinder 2 and connected to the inside of the drying cylinder 2. The connected hot blast stove 3, the drying cylinder 2 is provided with a lifting device 4, and the lifting device 4 includes a feed port 5 and a material receiving port 6 arranged at the bottom of the lifting device 4, and the top of the lifting device 4 is provided with There is feeding port 7. The interior of the drying cylinder 2 includes a drying section 8, a cold air section 9, and a displacement section 10 from top to bottom. The hot blast stove 3 is connected to the drying section 8, and the temperature g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com