Novel waste incineration device

A new type of waste incineration technology, which is applied in the field of environmental protection and sanitation treatment, can solve problems such as difficult to deal with if the temperature is not up to standard, and achieve the effects of increasing temperature, high calorific value, and reducing production and emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

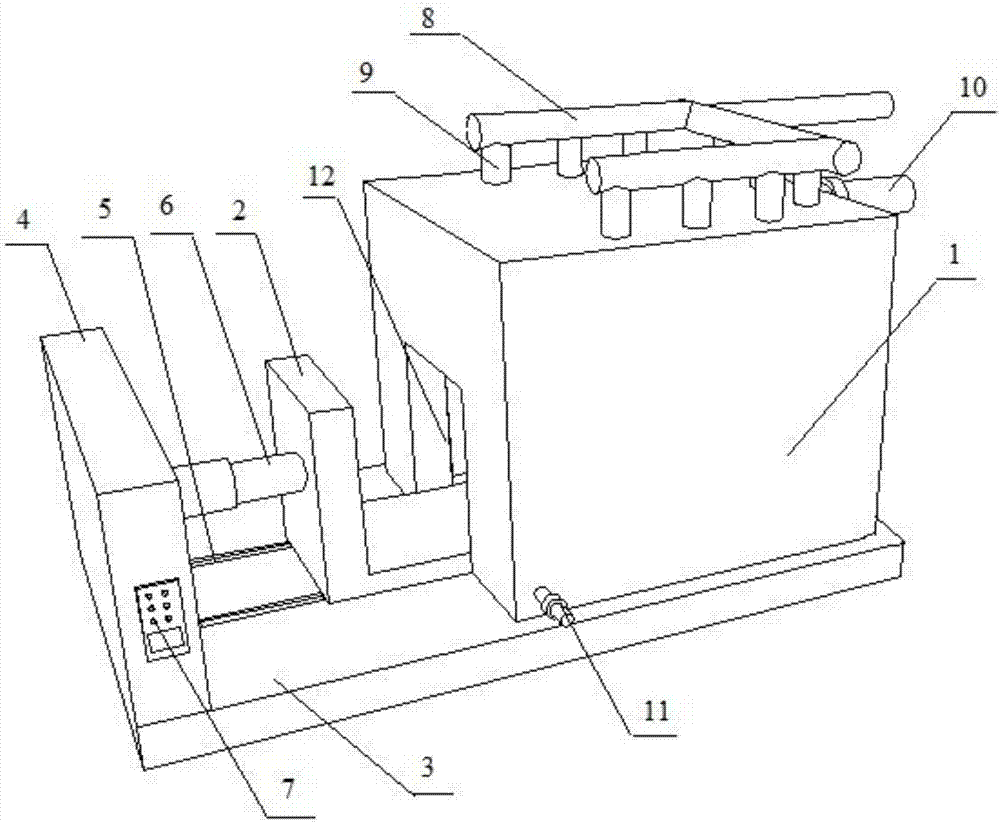

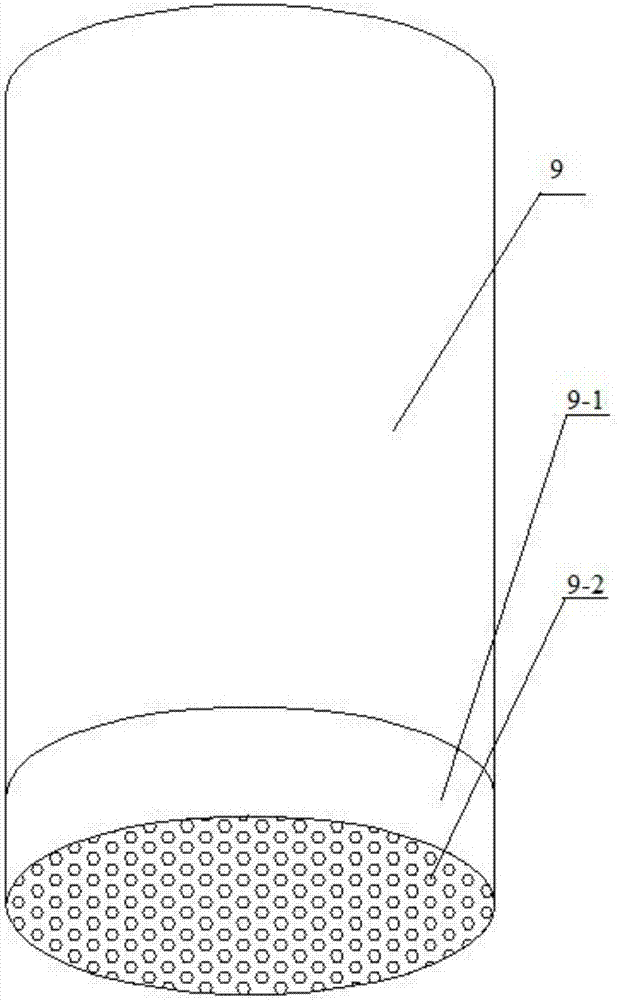

[0024] Such as figure 1 As shown, a new type of garbage incineration device includes an incineration chamber 1 arranged on a foundation 3. The incineration chamber 1 is provided with an inlet 12, an oxygen pipe 11, and an air outlet pipe 10 communicating with the interior of the incineration chamber 1, and the incineration The interior of the chamber 1 is provided with an ignition device, and the outside of the incineration chamber 1 is provided with a control ignition device and a control panel 7 for detecting the internal temperature of the incineration chamber 1, and the inlet 12 is provided with an inlet door 2 covering the inlet 12, It also includes a pressure pump and an oil storage tank. The top of the incineration chamber 1 is provided with a recovery oil injection pipe 8 connected to the pressure pump and the oil storage tank. A number of branch pipes extending into the incineration chamber 1 are evenly distributed on the recovery oil injection pipe 8 9. The recovery oi...

Embodiment 2

[0034] Further optimization is made on the basis of the new type garbage incineration device described in Example 1. The foundation 3 is provided with a slide rail 5 leading to the feed inlet 12, and a slide rail 5 is provided below the feed door 2 Corresponding to the sliding block, the outer end of the slide rail 5 is provided with a vertical fixed wall 4 parallel to the feed door 2, and a drive feed door 2 is provided between the fixed wall 4 and the feed door 2. The inert cylinder 6 sliding along the slide rail 5; in order to ensure the heat preservation effect, the thickness of the inlet door 2 is the same as that of the incineration chamber 1, and its weight often weighs hundreds of kilograms, which is difficult to move manually, and the temperature of the inlet door 2 is higher after incineration Persons approaching the feeding door 2 may be in danger of being scalded. The purpose of this embodiment is to solve the closing problem of the feeding door 2. It is controlled b...

Embodiment 3

[0036] Further optimization is made on the basis of the new type garbage incineration device described in embodiment 2. The control panel 7 is arranged on the fixed wall 4. The arrangement of this embodiment can make the control panel 7 far away from the incineration chamber 1 with higher temperature and avoid High temperature affects the service life of the control panel 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com