An equidistant keel cutting device

A cutting device and equidistant technology, which is applied to shearing devices, accessories of shearing machines, metal processing equipment, etc. Small and medium-sized enterprises, etc., to achieve the effect of strong novelty, low maintenance cost and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

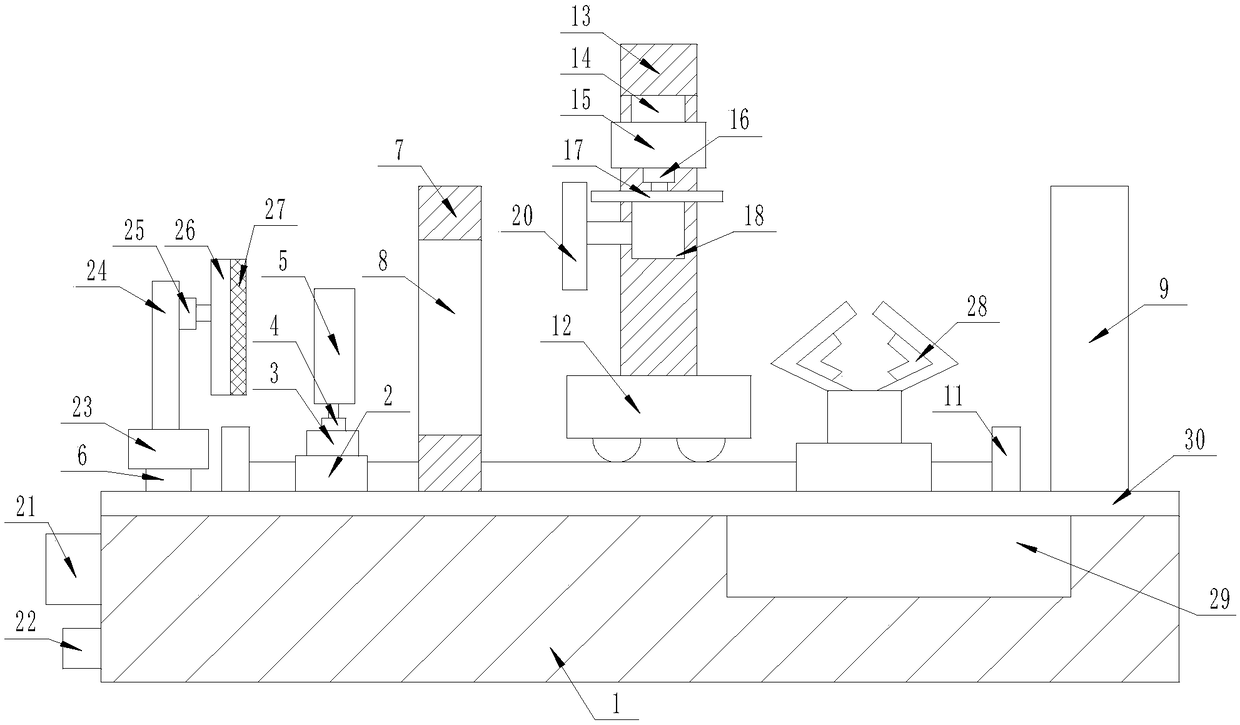

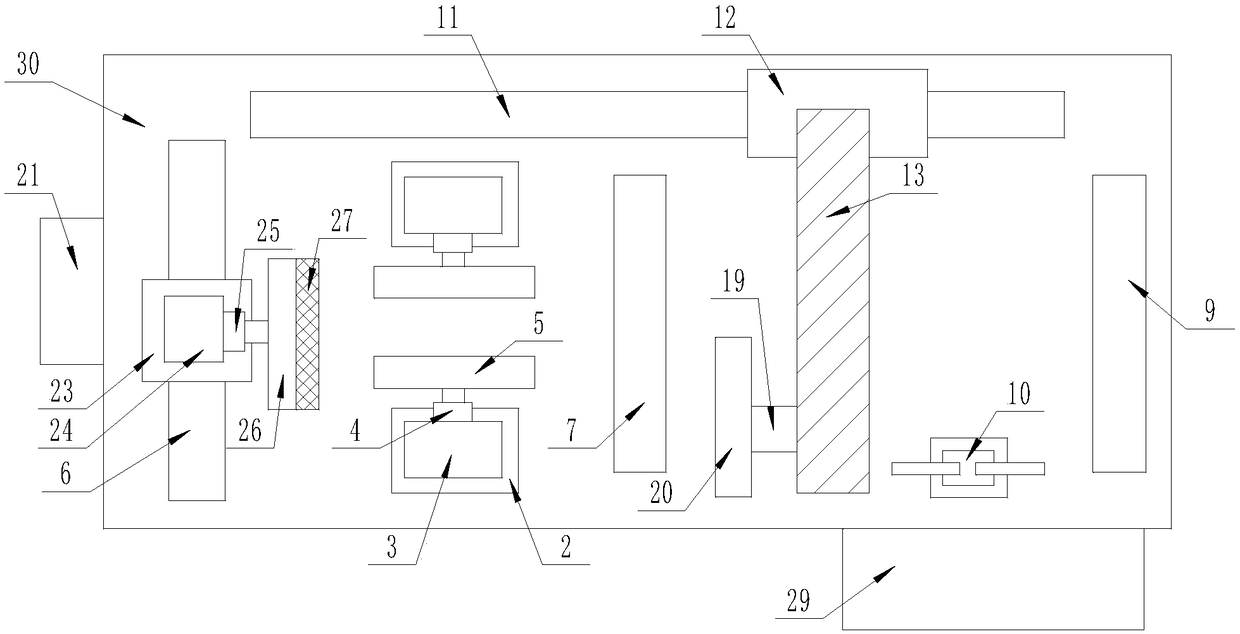

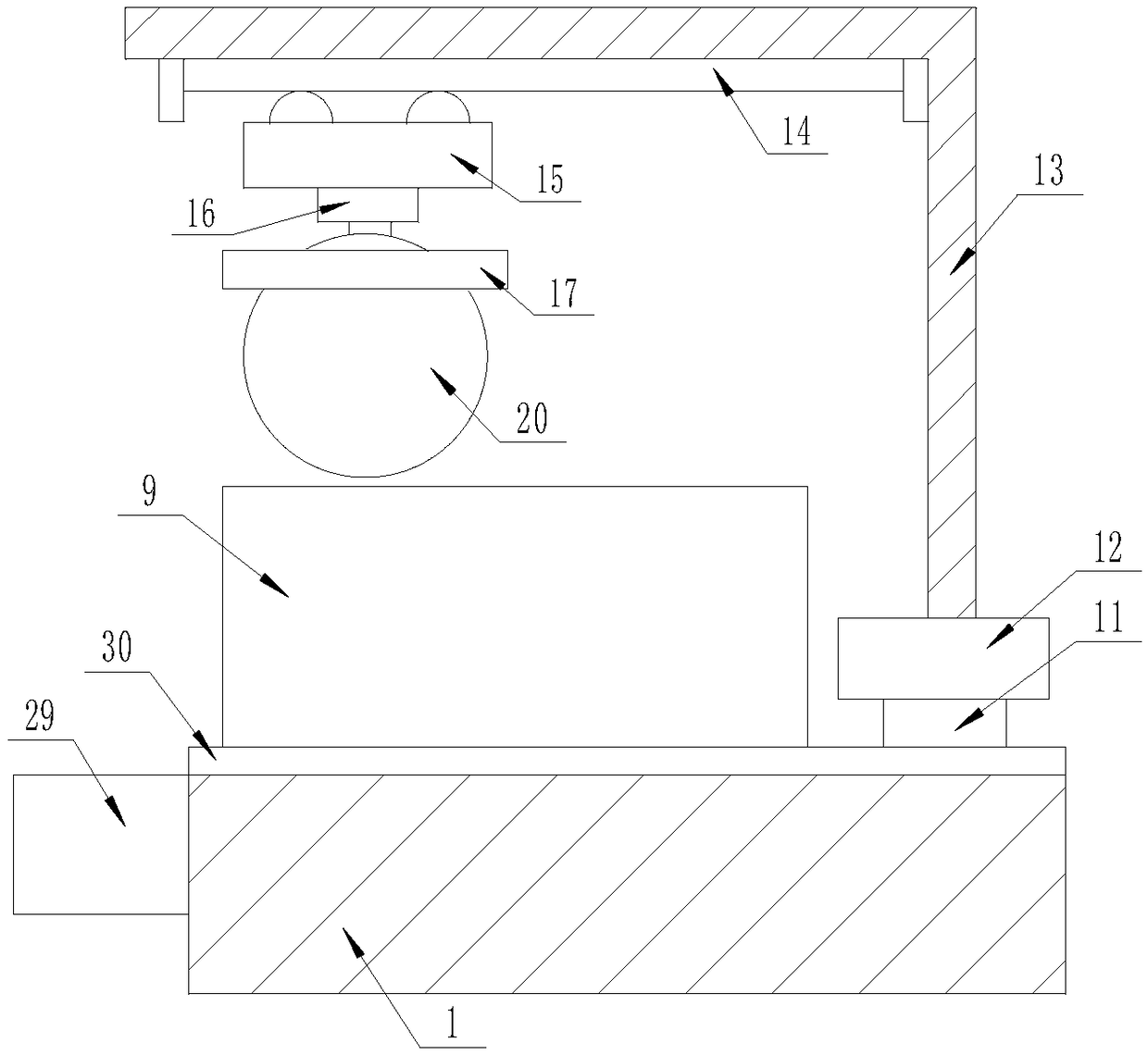

[0017] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, an equidistant keel cutting device includes a workbench 1, a set of installation blocks 2 are arranged at the center of the upper surface of the workbench 1, and a No. 1 installation box 3 is arranged on each of the installation blocks 2, and each The No. 1 installation box 3 is provided with a No. 1 linear motor 4 whose telescopic end is horizontal, and each No. 1 linear motor 4 telescopic end is provided with a splint 5, and one side of the upper surface of the workbench 1 is provided with There is a vertical slide rail 6, and the upper surface of the workbench 1 is provided with a vertical limiting plate 7 on one side of a set of mounting blocks 2, and a rectangular opening 8 is processed on the vertical limiting plate 7. The other side of the upper surface of the workbench 1 is provided with a No. 1 top plate 9. A mechanical gripper 10 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com