Multifunctional wiring harness tool plate jig

A wiring harness tooling board, multi-functional technology, applied in the direction of manufacturing wiring harnesses, electrical components, circuits, etc., can solve the problems of unadjustable placement angle of wiring boards, inconvenient for operators to use, and no storage wiring harnesses, etc. The effect of convenient lighting and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

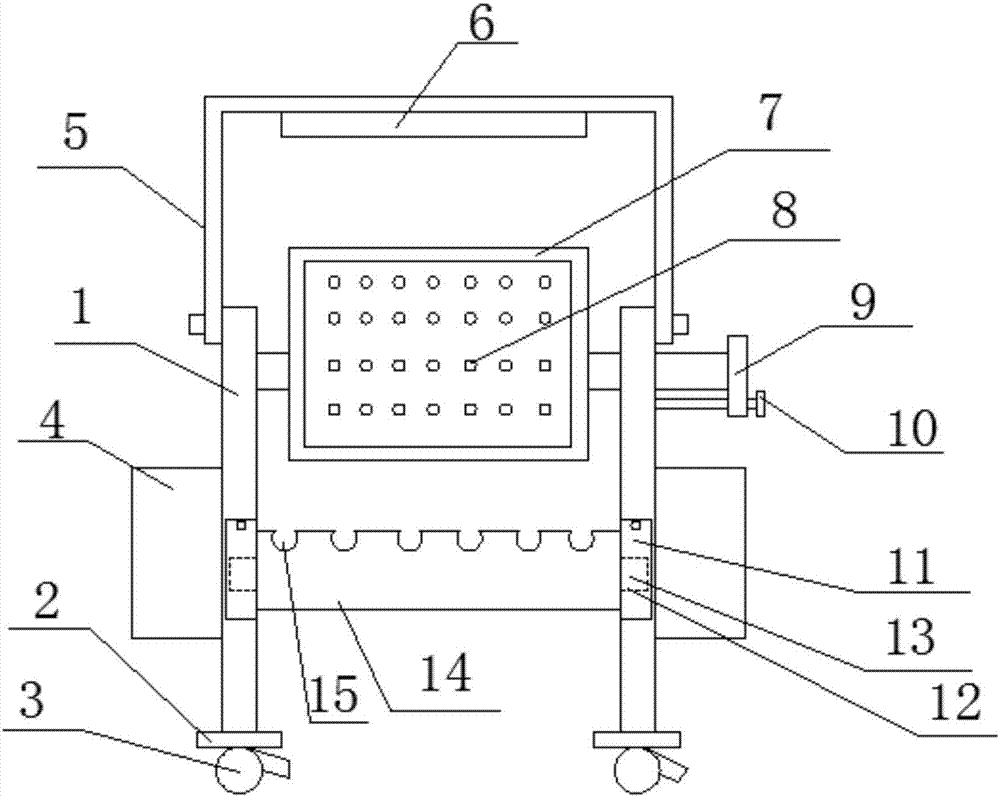

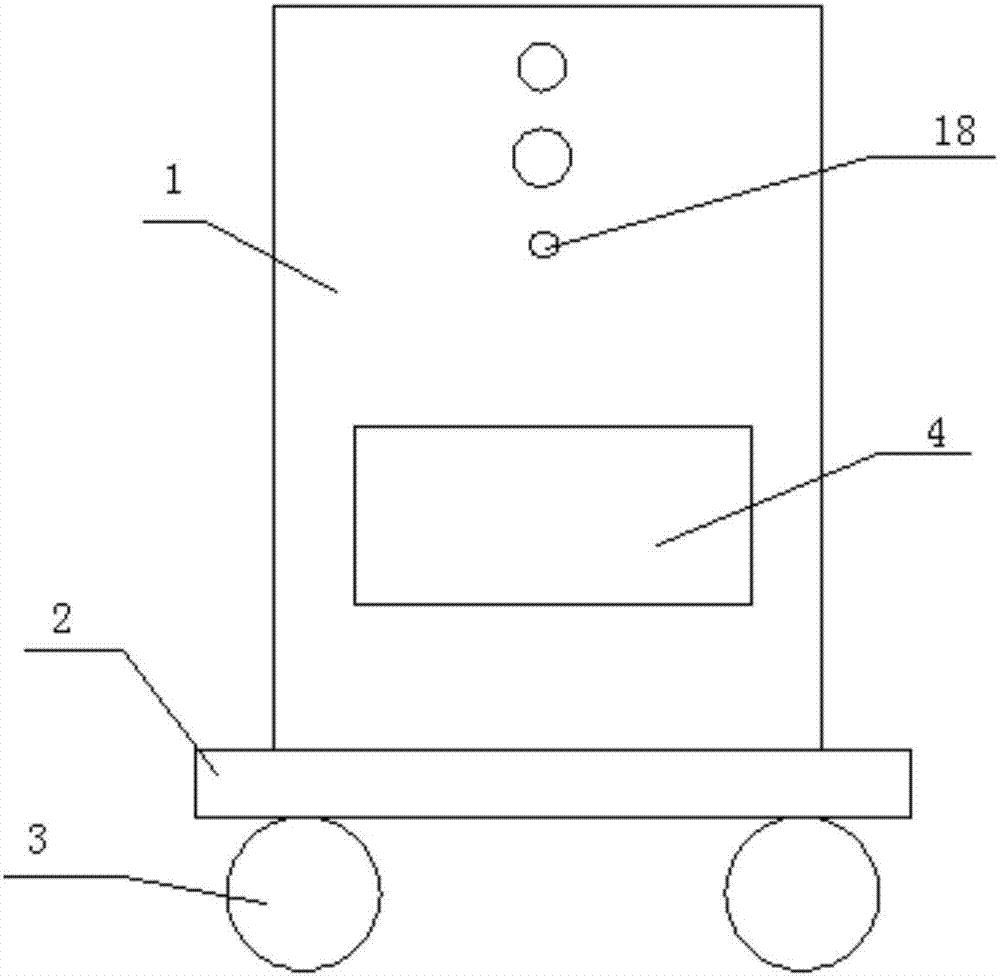

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

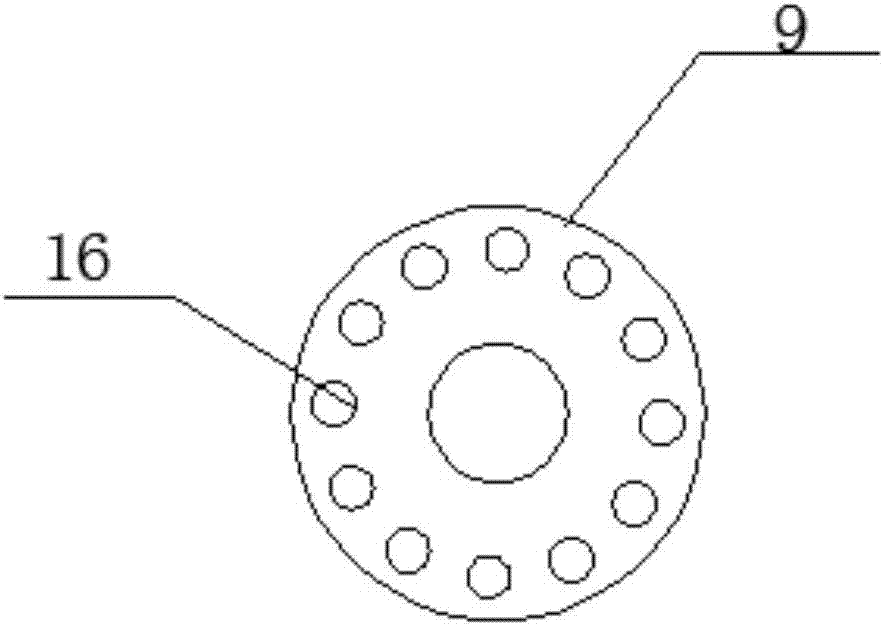

[0019] Figure 1-Figure 4 A specific embodiment of the present invention is shown: a multi-functional wire harness tooling board fixture, including a symmetrical support plate 1 and a wiring board 7, the bottom of the support plate 1 is provided with a mounting plate 2, and the bottom of the mounting plate 2 is provided with There are universal wheels 3, the two side walls of the wiring board 7 are provided with rotating shafts 19, the wiring board 7 is connected to the support plate 1 through the rotating shafts 19, and the side walls of the support plate 1 are provided with runners 9, One end of the runner 9 is connected with the rotating shaft 19, the runner 9 is provided with a plurality of through holes 16 along the circumferential direction of the runner 9, the through holes 16 are provided with positioning pins 10, the support plate 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com