An adjustable flextensional transducer

A flextensional transducer and adjustable technology, applied in the direction of instruments, sounding instruments, etc., can solve the problems of non-adjustability, unfavorable flextensional transducer characteristics research and performance optimization, etc., to increase adjustability, The effect of convenient operation and large adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

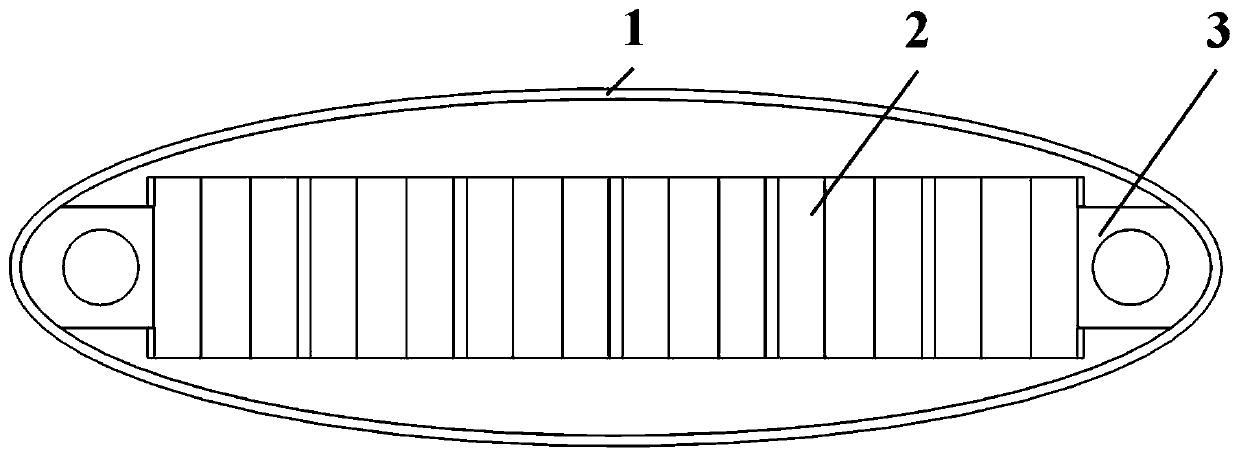

[0032] Such as figure 1 Shown is a schematic structural diagram of an adjustable flextensional transducer, which includes a flextensional housing 1, a drive assembly 2, and an adjustable transition block 3 connecting the two;

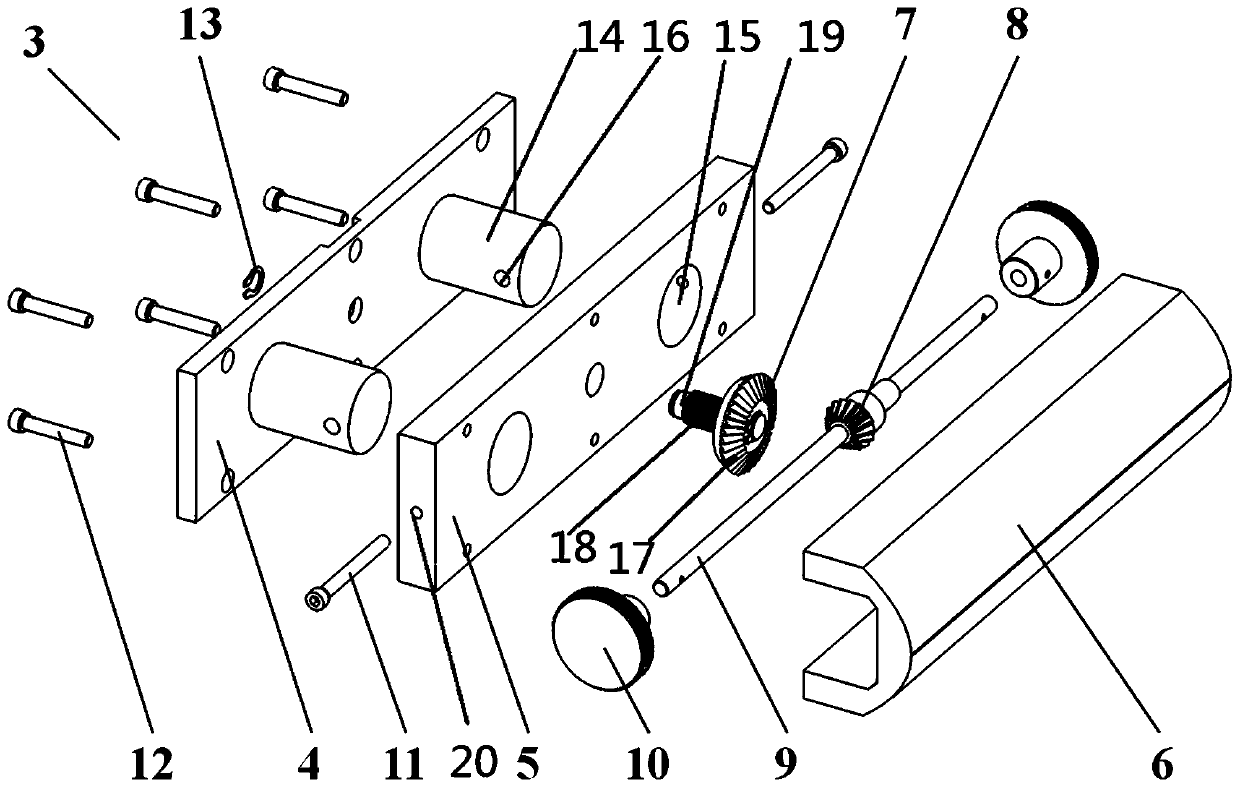

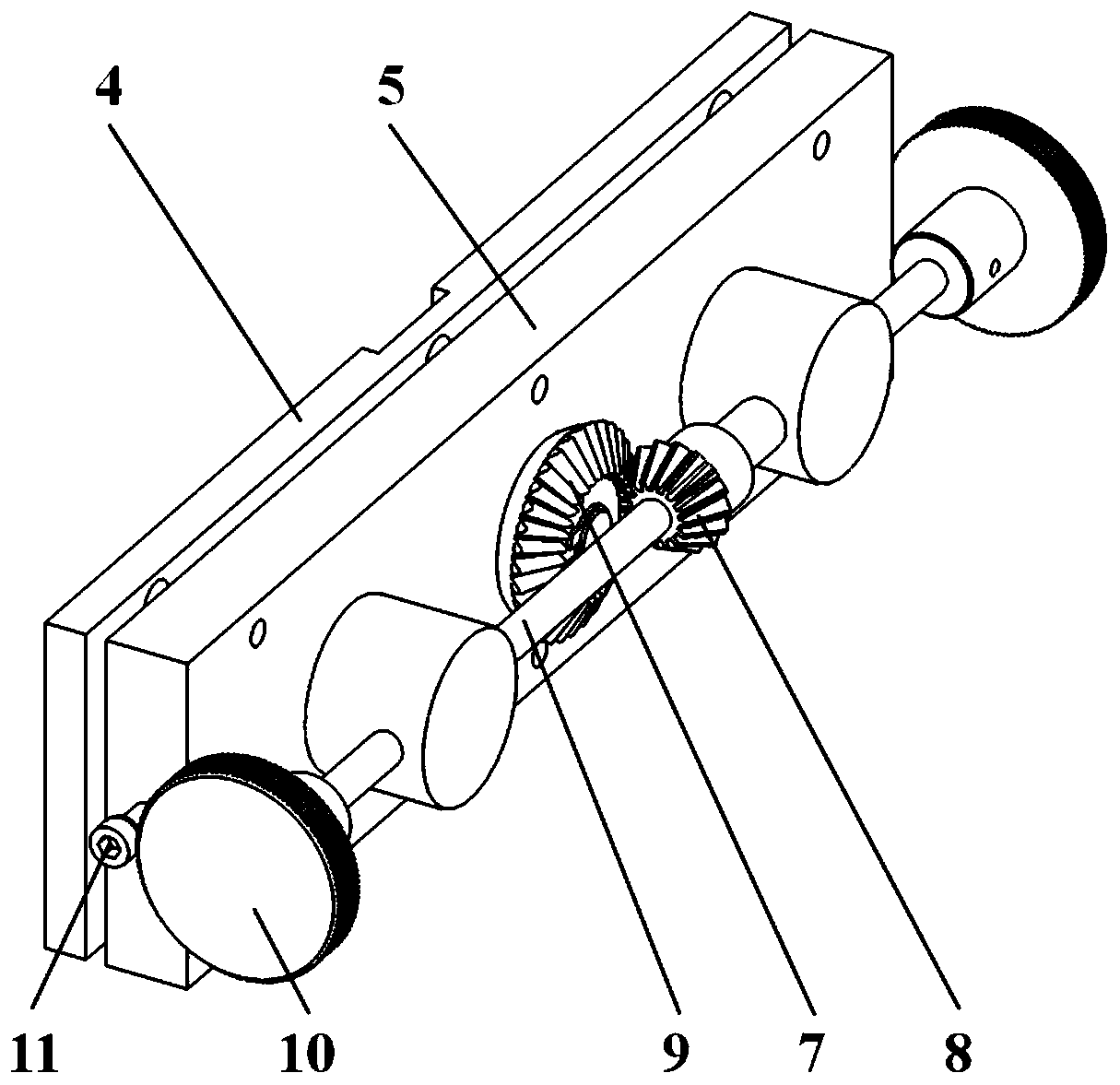

[0033] exist figure 2 and image 3 In the shown embodiment of the present invention, an adjustable transition block of an adjustable flextensional transducer includes a moving plate 4, a fixed plate 5, an outer curved surface cover 6, a large bevel gear 7, a small bevel gear 8, a transmission Shaft 9, handwheel 10, adjusting bolt 11, set bolt 12, elastic retaining ring 13.

[0034] One side of the motion plate 4 is provided with a groove matching the protrusion of the drive assembly 2, the other side of the motion plate 4 is designed with a motion guide post 14, and the corresponding fixed plate 5 is designed with a motion guide hole 15, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com