Suspension type drying room structure

A hanging type and drying room technology, applied in the direction of drying, drying machine, progressive drying machine, etc., can solve the problems of reducing the comfort of the operator's working environment, unable to dry the product, and poor sealing of the drying room , to achieve the effect of reducing human workload, improving drying processing efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Embodiment: a kind of suspended drying room structure, as Figure 1-6 As shown, it includes a three-dimensional frame with openings at the front and rear ends consisting of top plate 1, side plates 2 on left and right sides, and bottom plate 3. The inner surface of the top plate 1 is provided with a conveying structure, and the conveying structure includes a drive motor 4, Horizontal circulating conveyor chain 5 and several suspension rods 6, the drive motor 4 is located at both ends of the circular conveyor chain 5 and is fixedly connected with the top plate 1, and the upper ends of all the suspension rods 6 are equidistantly fixed on Move on the circulating conveyor chain 5 and driven by the circulating conveyor chain 5;

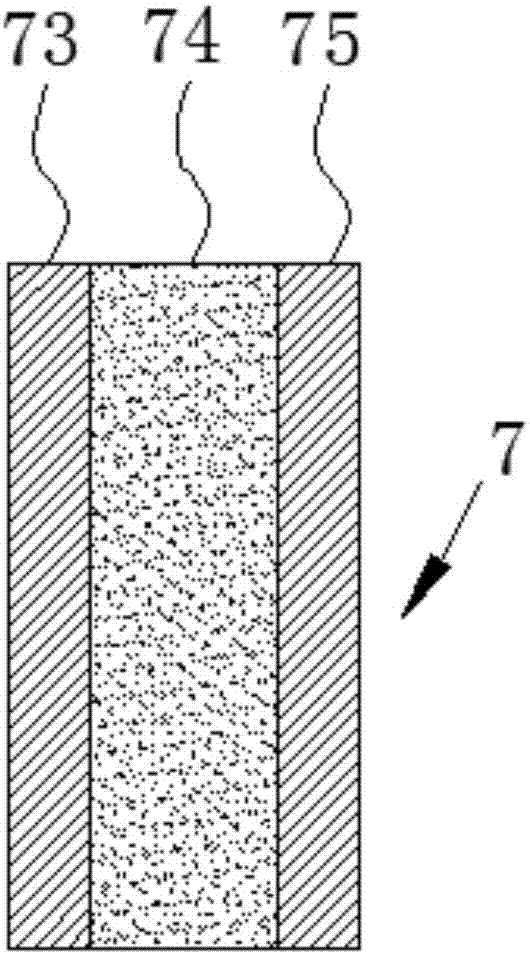

[0038] The top plate 1, the two side plates 2 and the bottom plate 3 are all spliced by several heat insulating plates 7, one end of the heat insulating plate 7 is a male end 71 and the opposite end is a female end 72 , the male end 71 and the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com