Sealing structure

A technology of sealing structure and sealing ring, which is applied to the sealing device of piston pump, machine/engine, pump components, etc., can solve problems such as failure, and achieve the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment takes a scroll compressor as an example to illustrate the implementation of the sealing structure according to the present invention. In addition to the scroll compressor, the present invention can be applied between relatively stationary shells, covers, plates and other parts. , especially on instruments with high sealing requirements due to the pressure difference between the cavity and the atmosphere.

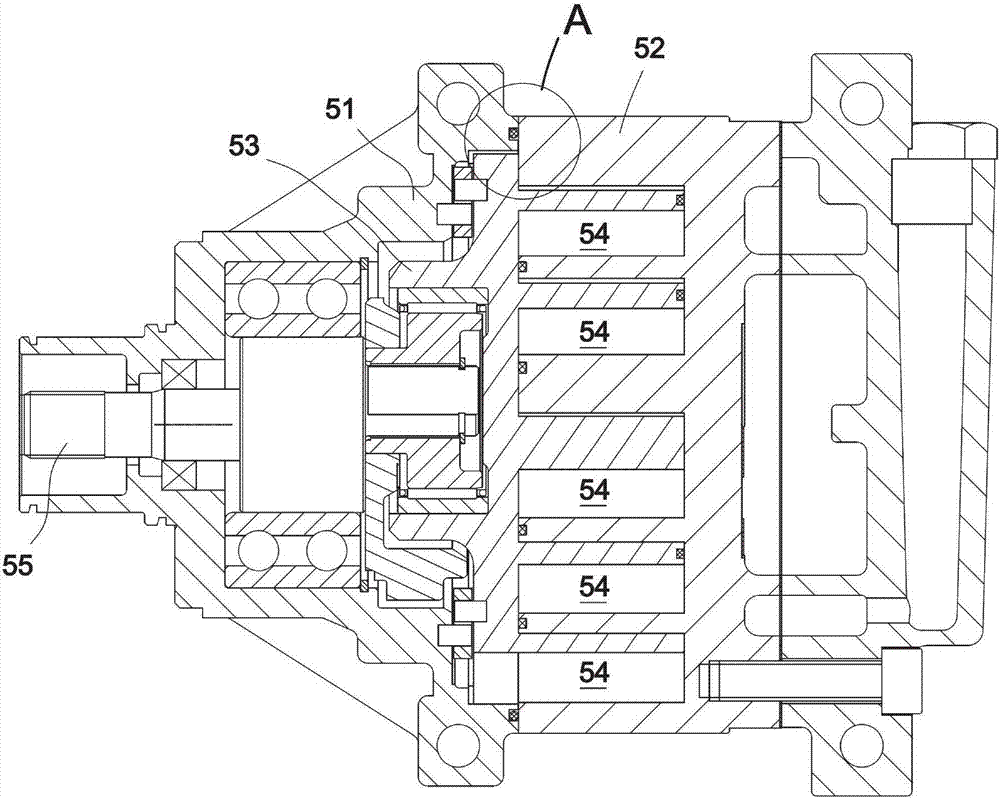

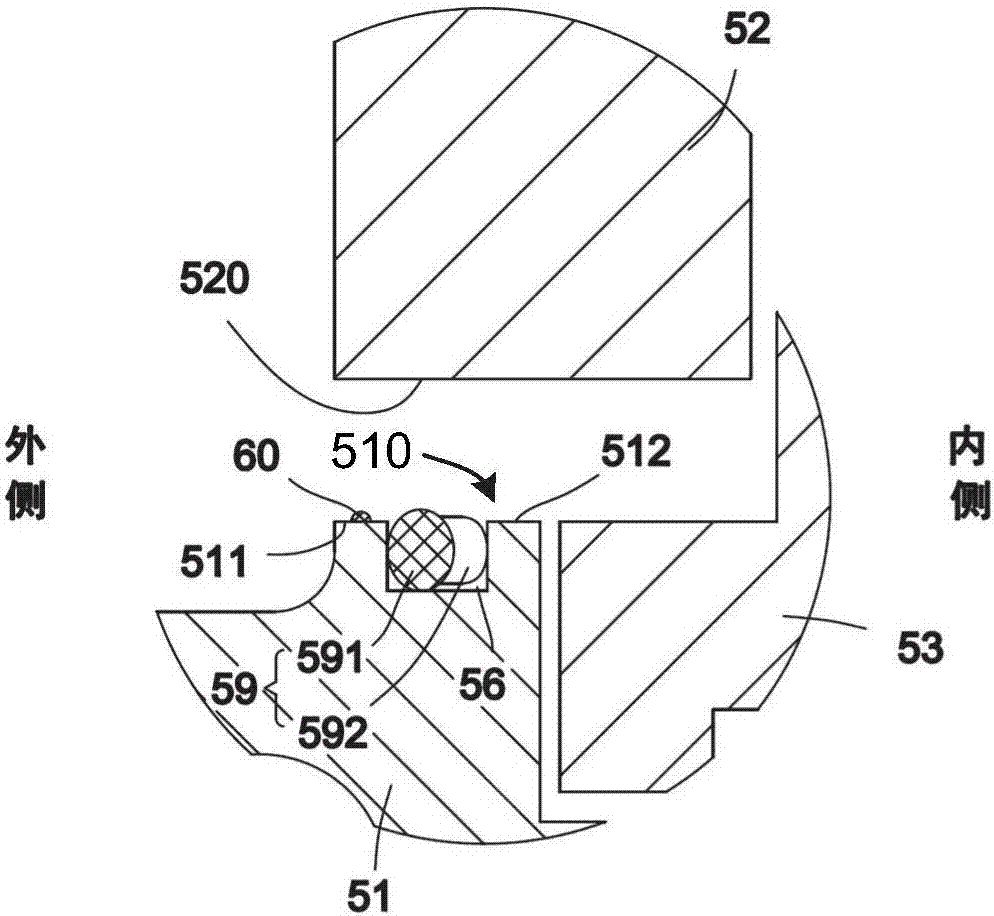

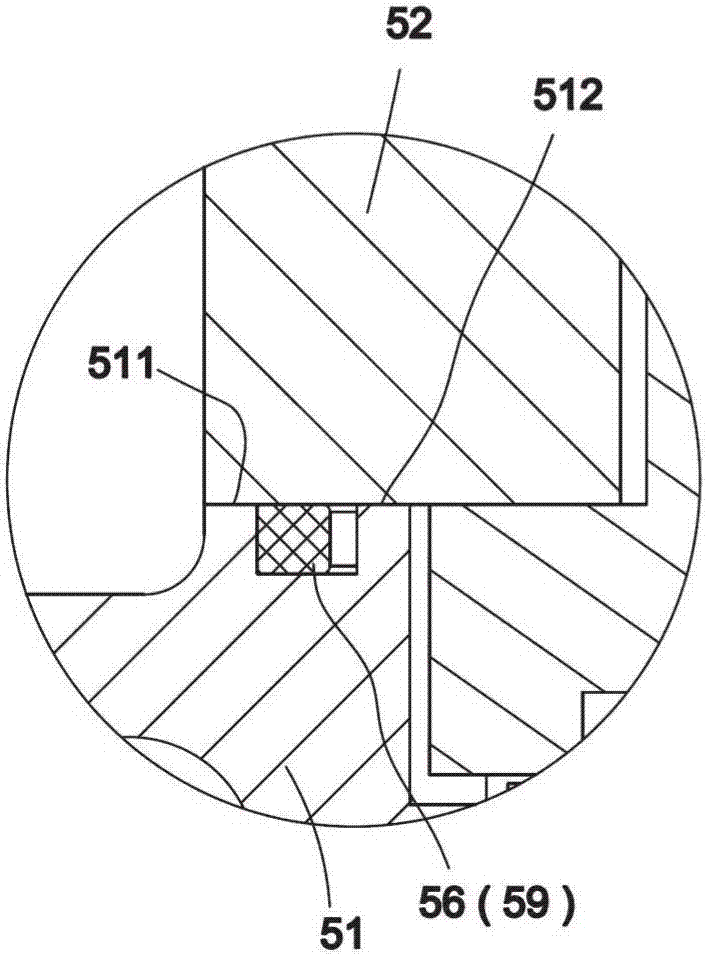

[0034] Such as picture 1 As shown, the compression assembly of the scroll compressor includes a movable scroll 53 and a fixed scroll 52 , which mesh with each other to enclose a plurality of compression chambers 54 . The fixed scroll 52 remains stationary, and the movable scroll 53 is driven by the crankshaft 55 to rotate eccentrically. The peripheral compression chamber 54 sucks the refrigerant, and the compression chamber 54 gradually moves to the center while shrinking in size. When it moves to the center, the refrigerant is discharged, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com