Novel fracturing chemical supporting coal bed gas mining method

A coalbed methane and chemical technology, applied in the fields of mining fluid, earth square drilling, climate sustainability, etc., can solve the problems of increasing coal permeability and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

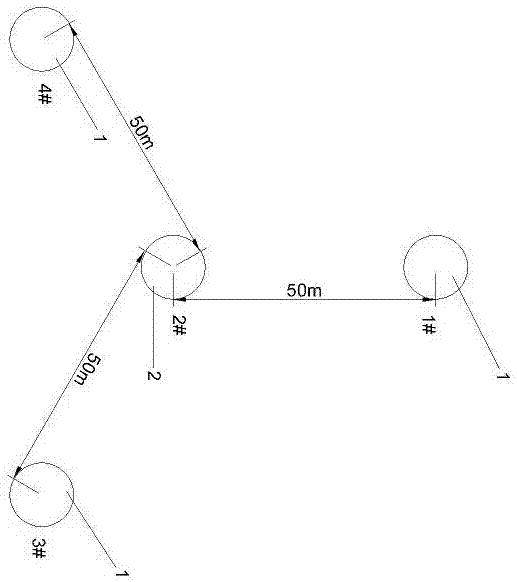

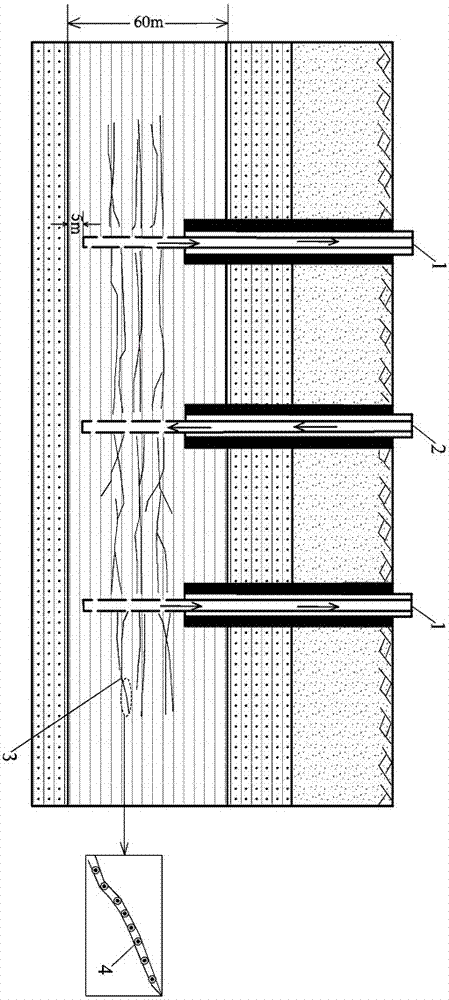

[0025] Embodiment 1: as figure 1 , 3 As shown, in a single coal seam with a thickness of 60m, the present invention is used to arrange 4 wells, and the distance between the surrounding wells and the central well is 50m, and they are distributed in an equilateral triangle with a center. Each well was drilled to the lower part of the target coal seam, and the bottom of the well was 5m away from the bottom of the ore seam. The target coal seam was divided into 6 sections according to the segmental height of 5m. saturated Ca(OH) 2 The solution is used as a fracturing fluid, and the fracturing is connected from the central well to the surrounding wells in each section from bottom to top; when all sections are fully fractured and connected, no pressure relief is performed, and the central well is used as the injection well to flow to the fracturing channel. Injection of high pressure CO 2 , to generate calcareous nodule proppant; after the fracturing and chemical support are comp...

Embodiment 2

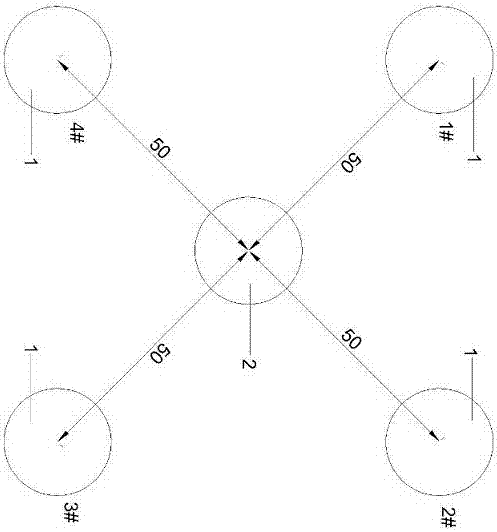

[0035] Embodiment 2: as figure 1 , 3 As shown, in a single coal seam with a thickness of 60m, 5 wells are arranged by the present invention, and the distance between the surrounding wells and the central well is 50m, which is distributed in the shape of a square. Each well was drilled to the lower part of the target coal seam, and the bottom of the well was 5m away from the bottom of the ore seam. The target coal seam was divided into 6 sections according to the segmental height of 5m. saturated Ca(OH) 2 The solution is used as a fracturing fluid, and the fracturing is connected from the central well to the surrounding wells in each section from bottom to top; when all sections are fully fractured and connected, no pressure relief is performed, and the central well is used as the injection well to flow to the fracturing channel. Injection of high pressure CO 2 , to generate calcareous nodule proppant; after the fracturing and chemical support are completed, the pressure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com