Automatic disc spring sealing compound ejection die

An automatic ejection and disc spring technology, applied in the field of molds, can solve problems such as inability to assemble, difficult assembly of bolts, easy to overflow into the inner hole of the skeleton, etc., to achieve strong competitiveness, reduce labor costs and risks, reduce labor costs and The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, the technical solution of the present invention will be described in detail through specific examples.

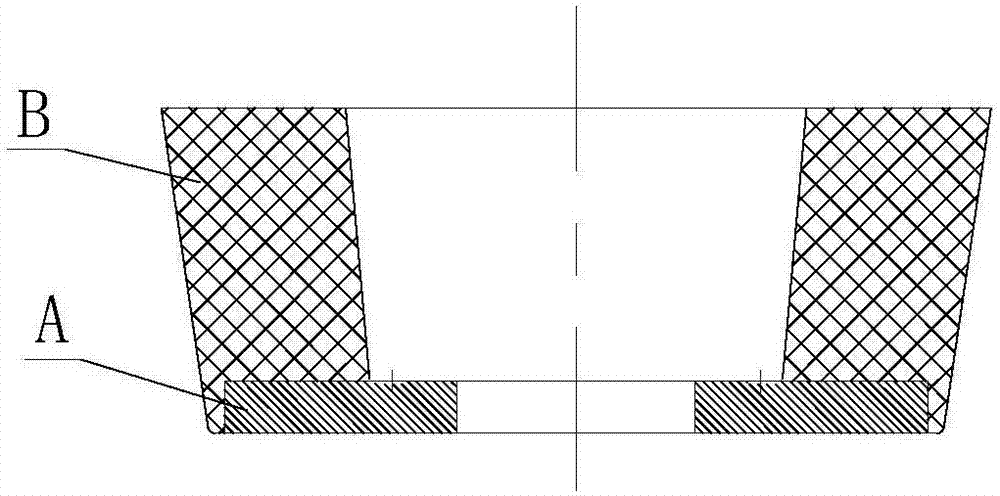

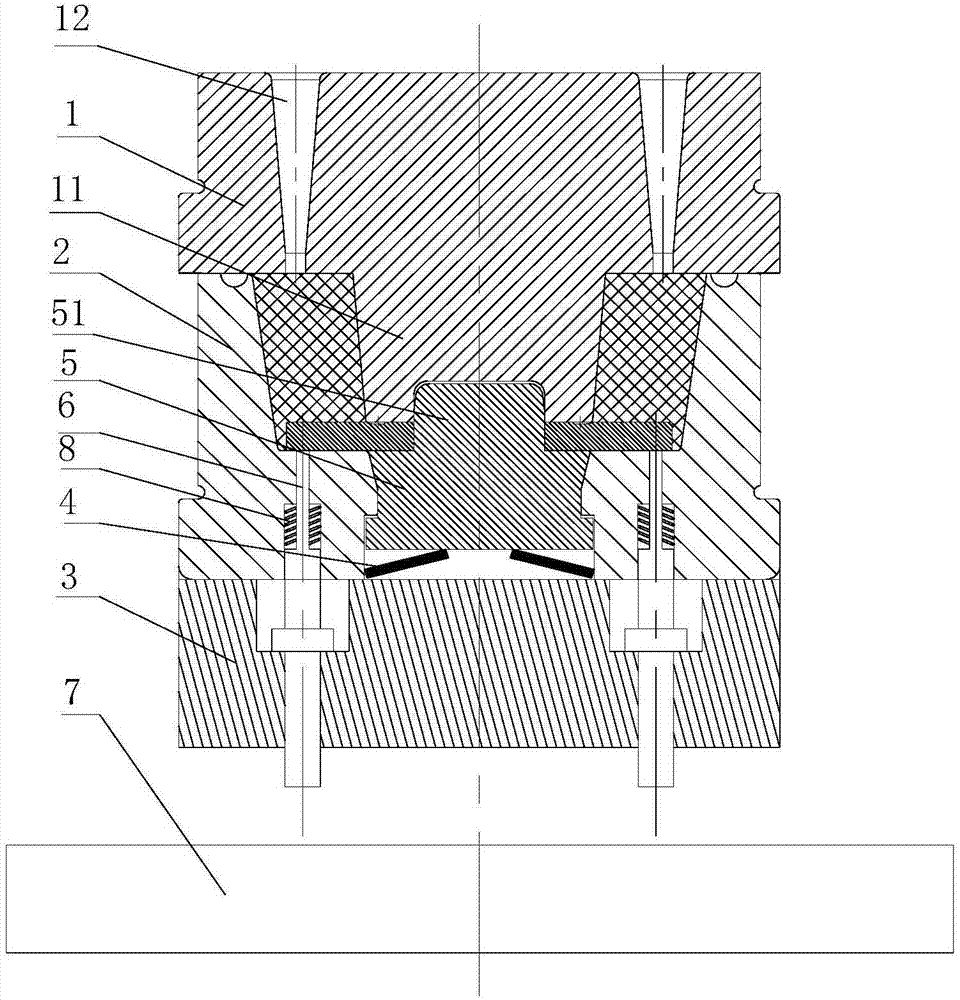

[0022] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of the product shown in the present invention; figure 2 It is a structural schematic diagram of a disc spring sealing automatic ejection mold proposed by the present invention.

[0023] refer to figure 2 , a disc spring sealing automatic ejection mold proposed in the embodiment of the present invention, comprising: an upper mold 1, a middle mold 2, a lower template 3 and an ejection mechanism, wherein:

[0024] The upper mold 1 is located above the middle mold 2, and the upper mold 1 is also provided with a glue injection port 12 that runs through its upper and lower end faces; the end of the upper mold 1 near the middle mold 2 is provided with a first raised portion 11, and the first raised portion 11 The ends have grooves. The middle mold 2 is positioned above the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com