Application of aminotriazolethione compounds as surface modifiers of metal sulfide minerals

A technology of aminotriazole thione and surface modifier, applied in solid separation, flotation and other directions, to achieve the effect of enhancing hydrophilicity, small dosage, and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

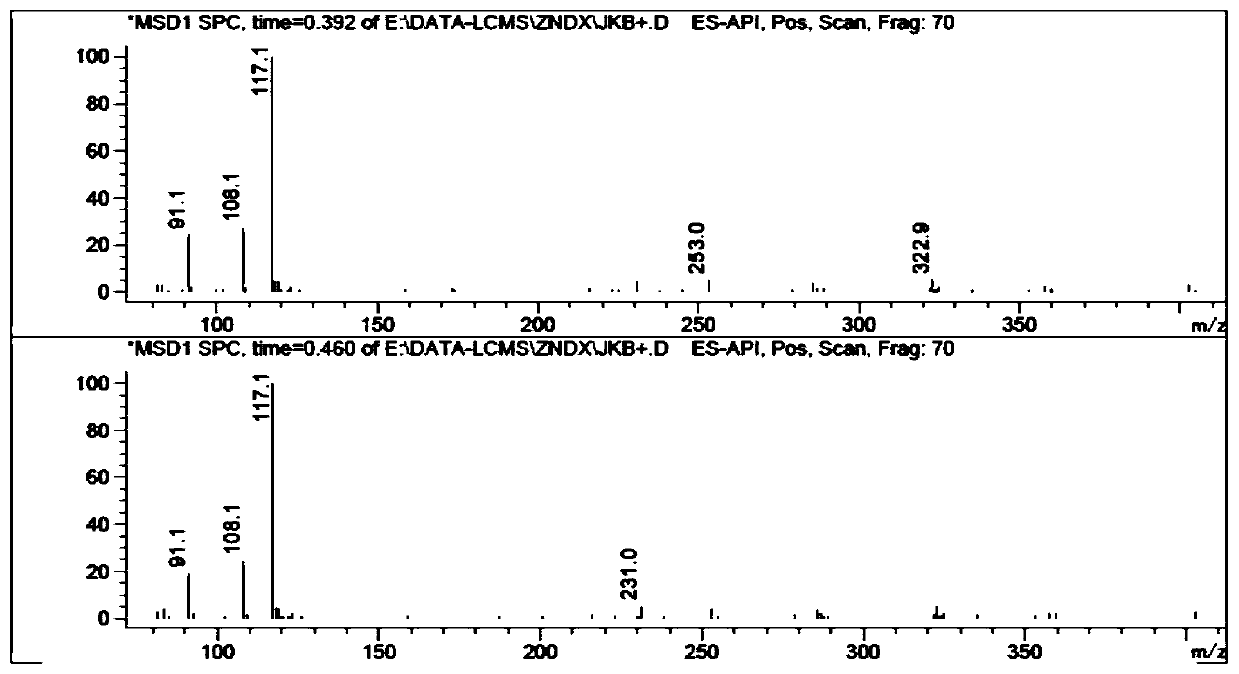

Image

Examples

Embodiment 1

[0028] Preparation of thioformyl dihydrazide

[0029] A certain amount of hydrazine hydrate and 2-chloroethanol were added to the three-necked flask equipped with a stirrer, a thermometer, a dropping funnel and a condenser, and the three-necked flask was placed in a constant temperature water bath at 0-5°C. A certain amount of carbon disulfide was slowly added dropwise, and the dropwise addition was completed within 1 h, and the temperature was controlled not to exceed 20 °C until yellow crystals were precipitated. A certain amount of lye is added, the temperature is raised and refluxed for several hours, and the tail gas is treated with lye. Cool to room temperature to obtain off-white product, which is filtered and dried to obtain thioformyl dihydrazide.

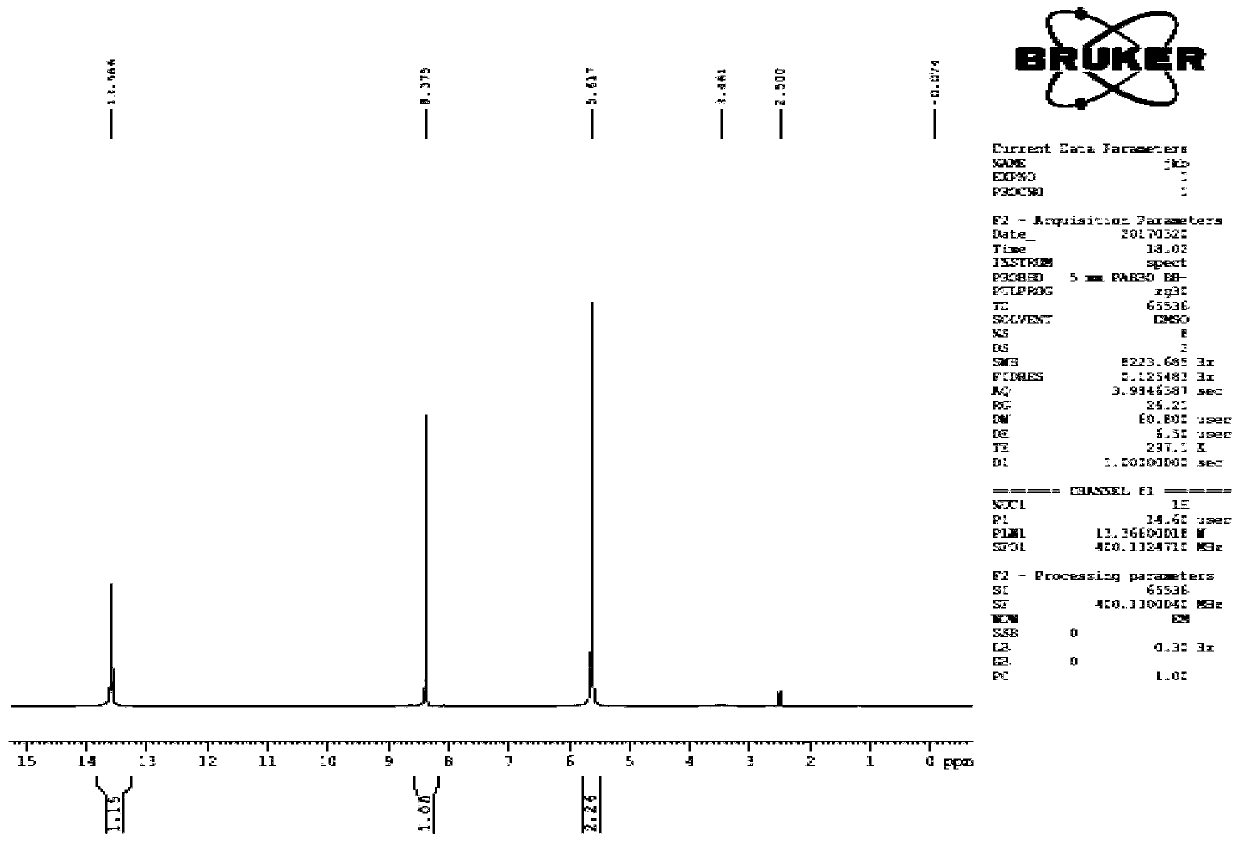

[0030] Preparation of 4-amino-1,2,4-triazole-5-thione

[0031]In a 250mL three-necked flask, add 0.1mol (10.6g) of thioformyl dihydrazide, add a certain amount of deionized water, and add concentrated hydrochloric acid t...

Embodiment 2

[0034] Using 4-amino-1,2,4-triazole-5-thione as an inhibitor, the flotation separation test of copper-molybdenum mixed flotation coarse concentrate in a processing plant in Henan was carried out. Its test procedure is as follows Figure 4 The results are shown in Table 1.

[0035] Table 1. 4-Amino-1,2,4-triazole-5-thione flotation test results

[0036]

Embodiment 3

[0038] Preparation of 4-amino-3-(2-hydroxy-2,3-dicarboxy)propyl-1,2,4-triazole-5-thione

[0039] In a 250mL three-necked flask, add 0.1mol (10.6g) of thioformyl dihydrazide, add a certain amount of deionized water, and add concentrated hydrochloric acid to adjust the pH to 5-7, place the three-necked flask in a water bath and heat to 100 At °C, the dropwise addition of an equivalent amount of an aqueous solution of citric acid (19.2 g) was started. The dropwise addition was completed within 0.5h, and the temperature was refluxed for 2h. After the reaction is completed, the temperature is cooled to separate out crystals, and the product is filtered and washed with cold deionized water,

[0040] Dry to obtain a solid product. Calculated based on thioformyl dihydrazide, the yield is 81%;

[0041] 4-Amino-3-(2-hydroxy-2,3-dicarboxy)propyl-1,2,4-triazole-5-thione Product structural formula:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com