Device for internal mashing for mud mixing

A mud, No. 1 technology, applied in the direction of grain processing, etc., can solve the problems of increasing labor intensity, large amount of use, increasing operation steps, etc., and achieve the effects of convenient walking, convenient breaking and simple operation.

Inactive Publication Date: 2017-08-11

浙江省二建建设集团有限公司

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Usually, when using mud mixture, it is usually operated manually. If the amount of use is relatively large, mechanical assistance is required. However, the traditional mixing is not very uniform. When using the mixture, fine particles will generate air bubbles. For high-rise buildings As far as the material is concerned, the safety factor is reduced. If the particles are encountered during use, they are usually crushed manually, which increases the operation steps, increases the labor intensity, and reduces the work efficiency. The crushing of the existing technology will get the soil There are no effective interception, so in order to solve these situations, it is necessary to design a new type of crushing device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

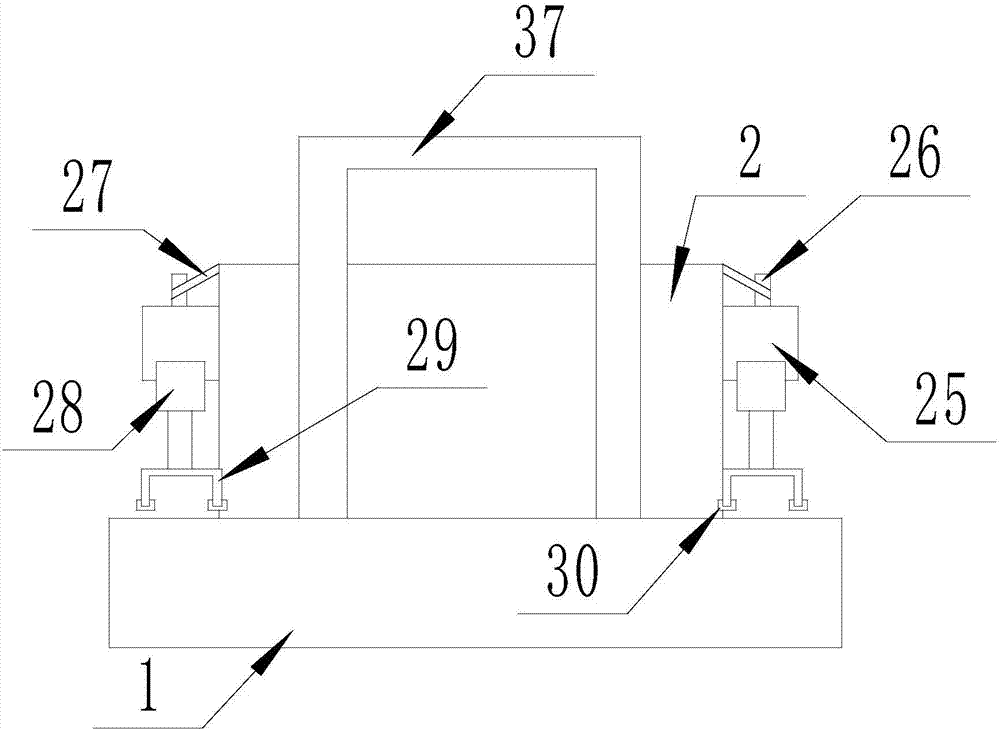

[0025] Embodiment 2: The set screw 5 can be replaced by a folding fastening frame, which can also achieve the effect of fixing, and other structures are the same as in Embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

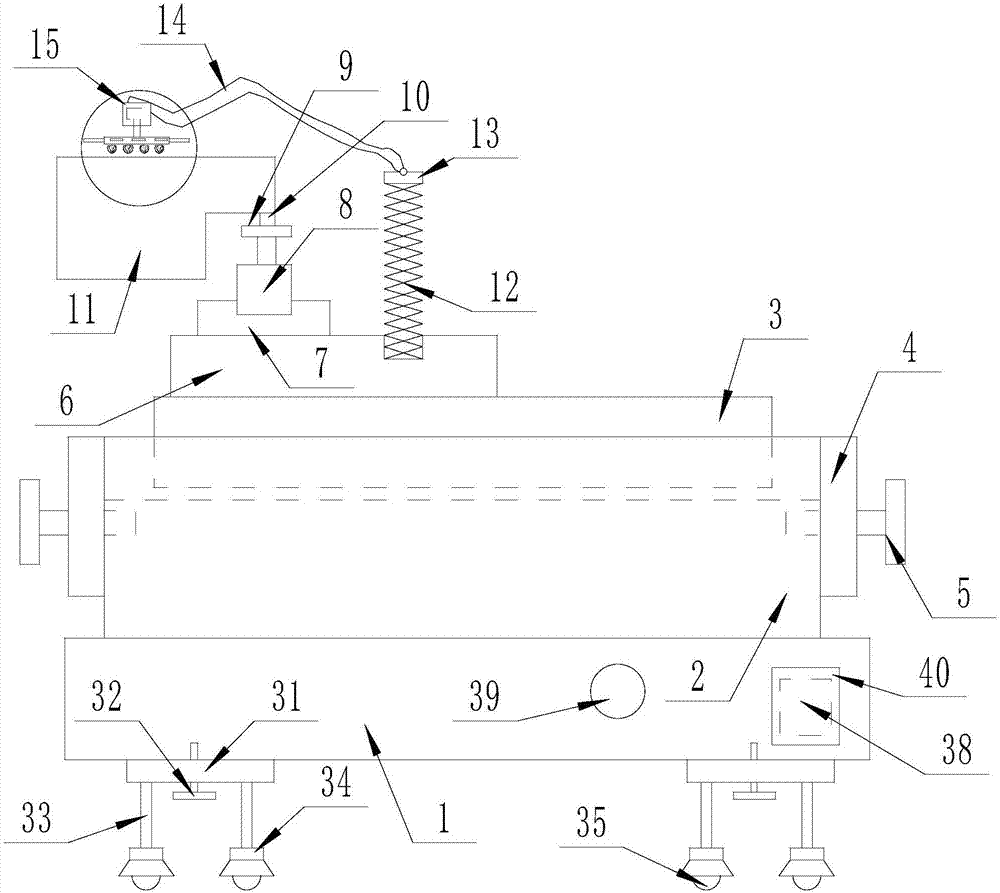

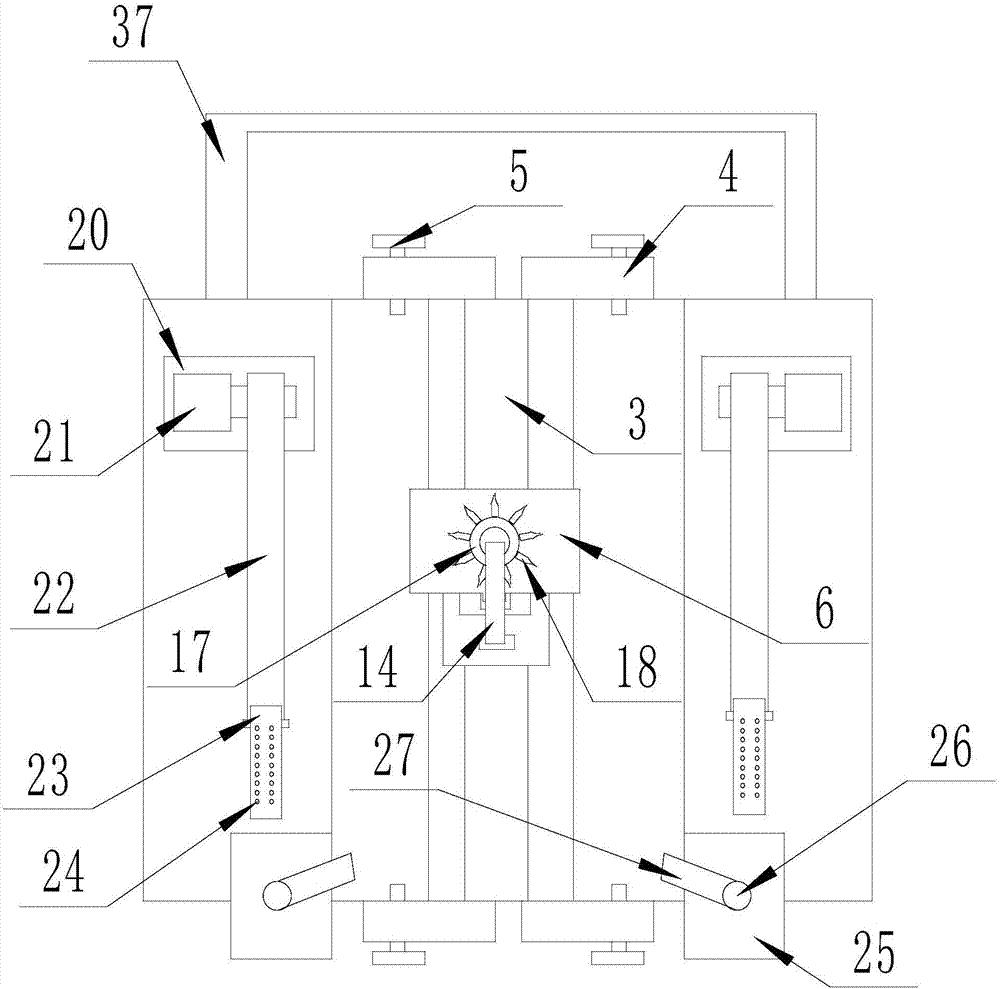

The invention discloses a device for internal mashing for mud mixing. The device comprises a first strip-shaped bearing base, wherein a strip-shaped hollow bearing box is formed in the upper surface of the first strip-shaped bearing base; an internal mashing mechanism is arranged on the upper surface of the strip-shaped hollow bearing box; a movement mechanism is arranged on the lower surface of the first strip-shaped bearing base; a fixation mechanism is arranged on the side surface of the strip-shaped hollow bearing box; and swinging agglomerate removal mechanisms are arranged on the upper surface of the first strip-shaped bearing base and located at the two sides of the strip-shaped hollow bearing box. The device disclosed by the invention has the following beneficial effects: the device is good in internal crushing effect on the encircled soil pile, convenient in crushing for a soil pile outside the encircled soil pile, convenient to travel, simple to operate, and capable of reducing internal particles.

Description

technical field [0001] The invention relates to the field of building appliances, in particular to a device used for mud mixing and internal crushing. Background technique [0002] Mud is the material used to build houses by mixing soil and water evenly. Due to the different soil conditions, there are usually crusted particles in the mixed mixture that are not uniformly mixed with it. [0003] Usually, when using mud mixture, it is usually operated manually. If the amount of use is relatively large, mechanical assistance is required. However, the traditional mixing is not very uniform. When using the mixture, fine particles will generate air bubbles. For high-rise buildings As far as the material is concerned, the safety factor is reduced. If the particles are encountered during use, they are usually crushed manually, which increases the operation steps, increases the labor intensity, and reduces the work efficiency. The crushing of the existing technology will get the soil ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B02C21/02B02C18/14B02C18/16B02C19/00B02C23/00

CPCB02C18/143B02C18/16B02C19/00B02C21/02B02C23/00

Inventor 余文煜

Owner 浙江省二建建设集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com