Proportional pressure solenoid valve

A solenoid valve and pressure technology, which is applied in the field of proportional pressure valves, can solve problems such as slow response and increased difficulty in precise control of liquid pressure, and achieve the effects of fast response, stable pressure control, and stable output pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

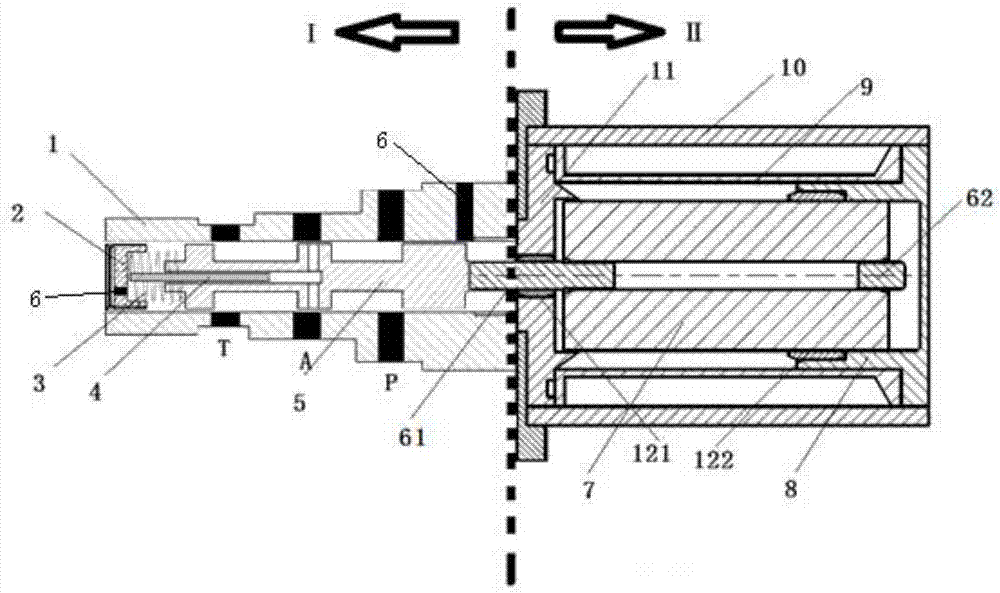

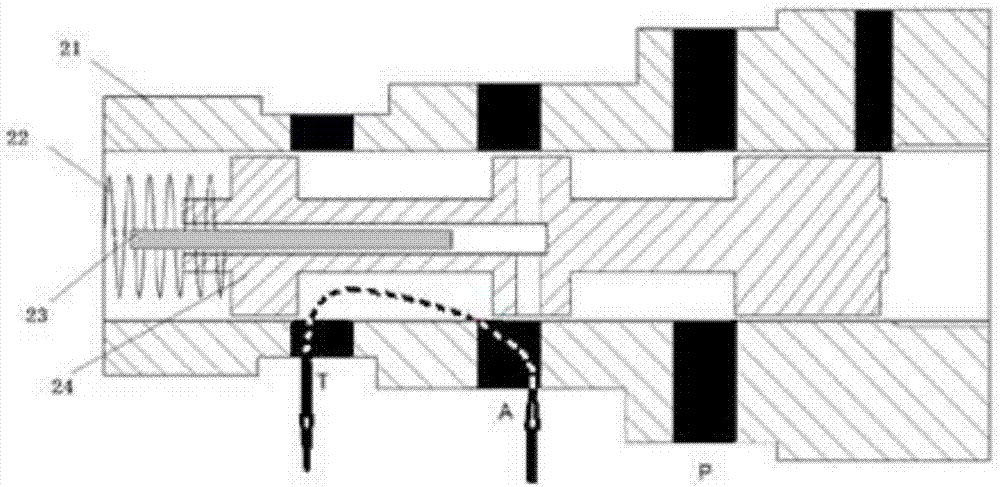

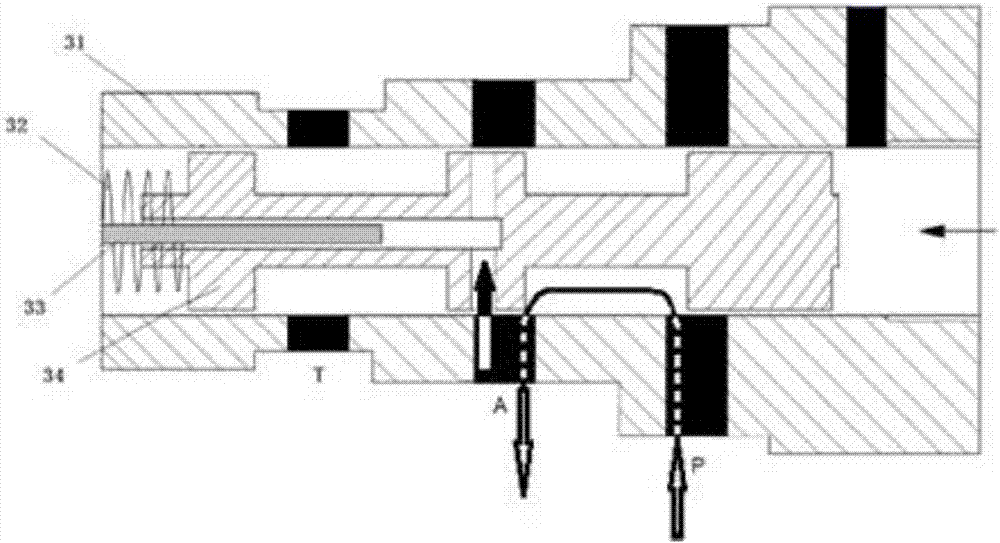

[0016] Such as figure 1 As shown, a proportional pressure solenoid valve with a feedback lever is divided into hydraulic part Ⅰ and electromagnetic part Ⅱ. Hydraulic part I includes valve body 1 , plug 2 , balance spring 3 , feedback rod 4 and spool 5 . The valve body 1 of the hydraulic part I is provided with a pressure fluid input port P, an output port A and a pressure relief port T, which are respectively connected to a pressure source, a pressure load and an oil storage container during operation. The T port leakage 6 is respectively arranged on the valve body 1 and the plug 2, and communicates with the pressure relief port T under different working conditions. The spool 5 is installed in the cavity of the valve body 1, one end of the spool 5 is sealed and the other end opens the cavity, the sealing end is offset against the large ejector rod 61 of the electromagnetic part, and the cavity end forms a feedback with the feedback rod 4 freely floating in the cavity. cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com